Filling valve for filling machine

A filling valve and filling machine technology, applied in packaging, valve details, valve devices, etc., can solve the problems of freezing the filling valve, liquid is prone to freezing, and the valve body does not have anti-freezing function, so as to prevent Frozen effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

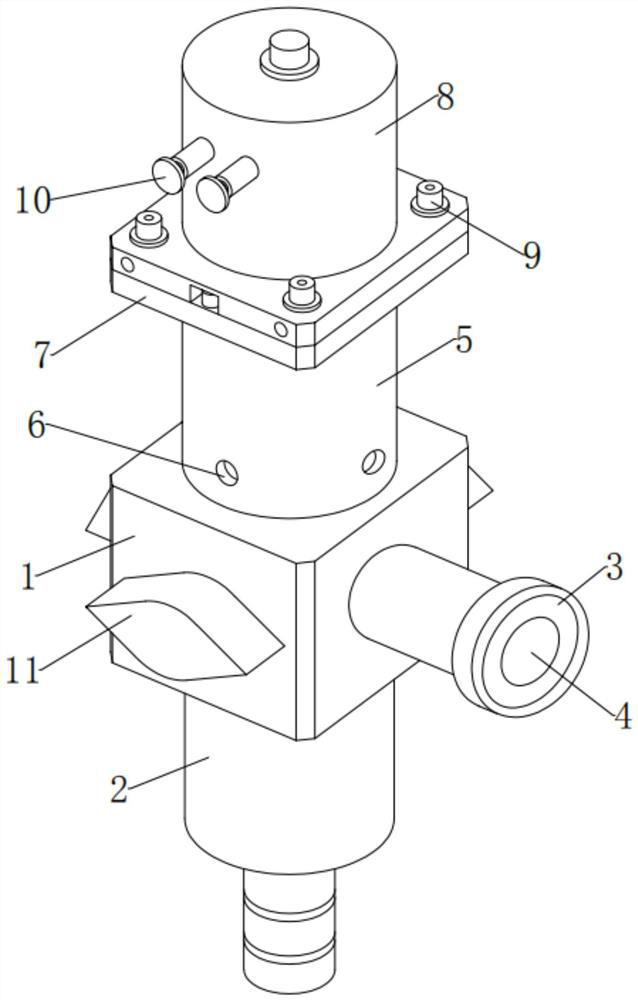

[0046] see Figure 1-2 , in an embodiment of the present invention, a filling valve for a filling machine, comprising:

[0047] Valve body 1, the central position of the bottom end of the valve body 1 is fixedly installed with the filling nozzle 2, the central position of the outer surface on the right side of the valve body 1 is fixedly installed with the input connecting pipe 3, and the central position of the right side of the input connecting pipe 3 is provided with a valve Inlet 4, the top central position of the valve body 1 is fixedly installed with a connecting seat 5, the four corners of the lower end of the connecting seat 5 are movable and installed with set screws 6, and the top position of the connecting seat 5 is fixedly installed with an end plate 7, an end plate 7 A cylinder 8 is fixedly installed at the central position of the top end, bolt assemblies 9 are movably installed at the top four corners of the end plate 7, and two interface pieces 10 are fixedly in...

Embodiment 2

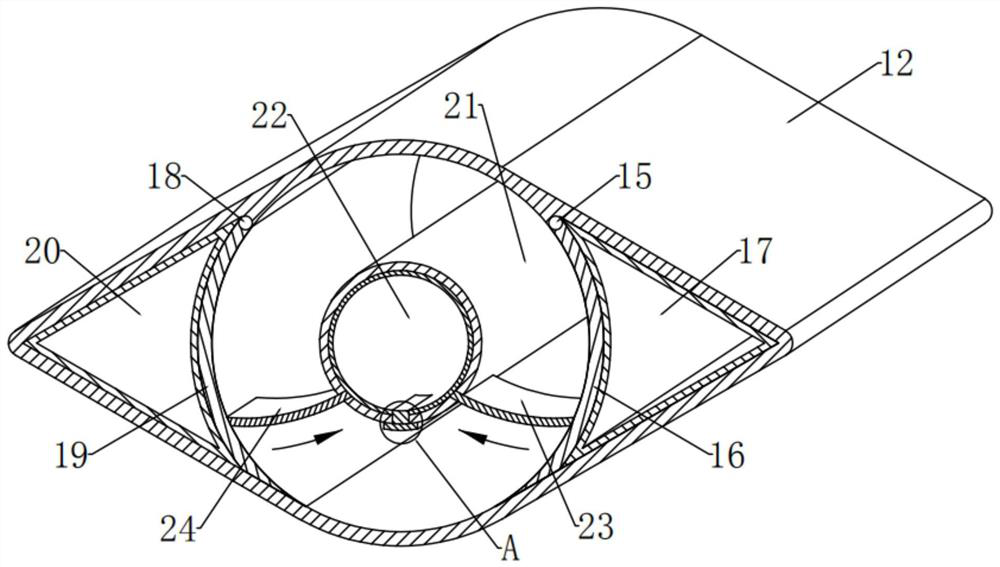

[0058] see figure 2 , Figure 4-5 Compared with Embodiment 1, the embodiment of the present invention differs in that: the preprocessing component 13 includes:

[0059] Right shaft 15, the upper end of the right inner wall of the housing 12 is rotated in the front and rear horizontal direction, and the right shaft 15 is installed, and the front and rear ends of the right shaft 15 are rotatably installed at the upper right end of the front and rear inner walls of the housing 12;

[0060] Right rotating plate 16, the outer surface of the bottom side of right rotating shaft 15 is surrounded and fixedly installed with right rotating plate 16. It has a magnetic property different from that of the housing 12, and the bottom outer surface of the right rotating plate 16 is magnetically attracted to the lower surface of the right inner wall of the housing 12 under normal conditions;

[0061] Here, the right turning plate 16 has an outward appearance on a longitudinal section in the ...

Embodiment 3

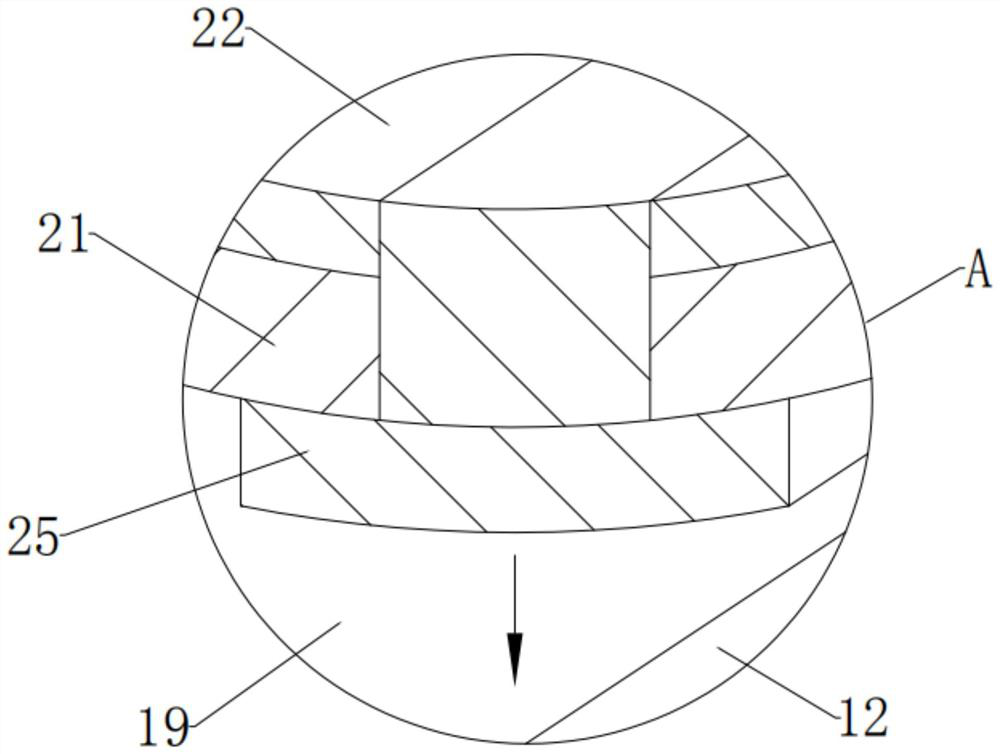

[0074] see Figure 2-4 and Image 6 Compared with Embodiment 1, the embodiment of the present invention differs in that: the heating assembly 14 includes:

[0075] Inner shell 21, the inner shell 21 is fixedly installed in the central position of the shell 12, the appearance of the inner shell 21 is a hollow circular shape on a longitudinal section, and the outer surfaces of the front and rear sides of the inner shell 21 are fixedly mounted on the shell 12 The inner diameter of the inner shell 21 is 2 / 3 of the inner diameter of the housing 12, and the right lower end and the lower left end of the inner shell 21 are obliquely penetrated with a right chute and a left chute, and the bottom end of the inner shell 21 There is a through groove through the upper and lower ends at the middle end of the front part;

[0076] Here, the inner casing 21 and its appearance are set as a hollow circular shape on a longitudinal section, and its inner diameter is 2 / 3 of the inner diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com