Operation method of washing machine and washing machine

An operation method and washing machine technology, which are applied in the control device, washing device, textile and paper making of washing machines, etc., can solve the problems of eccentricity of the inner tub and impact on the shell of the washing machine, and achieve the purpose of prolonging the service life, reducing the time of dehydration, and improving the user experience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0128] Most of the inner tubs of existing washing machines are perforated, and the inner tub and the outer tub are connected, and dehydration can be realized by detecting the water level through a water level sensor.

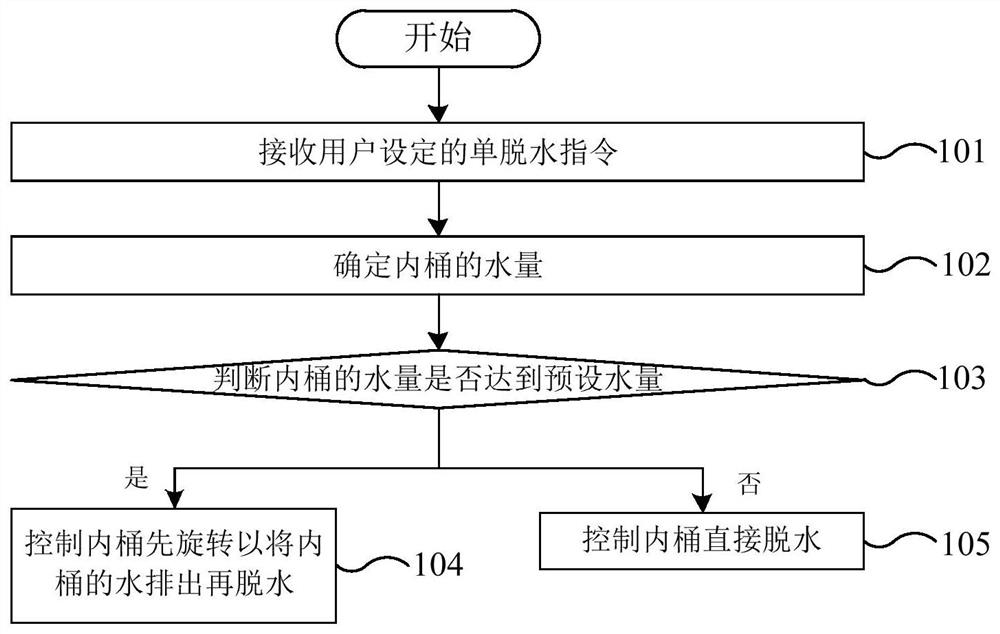

[0129] However, the non-porous inner tub (that is, the inner tub as a water bucket) cannot communicate with the outer tub. When the user chooses single dehydration, it is impossible to judge whether the user uses the washing machine for separate dehydration after hand-washing clothes, or whether the user wants to dehydrate during the washing process. Power outage or water accumulation in the barrel caused by power outage is drained. Based on this, the present invention proposes a dehydration control method for the non-porous inner barrel.

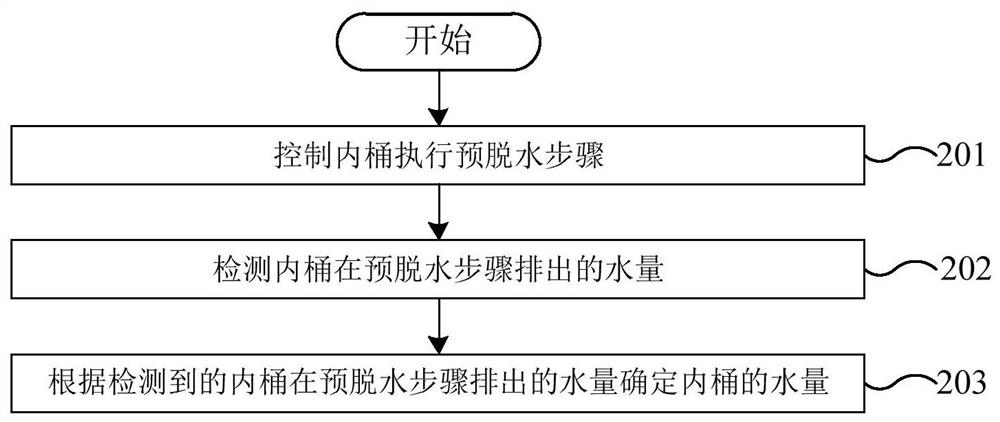

[0130] Specifically, when the user selects single dehydration, the frequency value of the water level in the outer tub of the washing machine is detected first, if it is detected that the water level is above the water level o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com