Novel high-pressure plunger pump fluid end structure

A high-pressure plunger pump and hydraulic end technology, which is applied in the field of the hydraulic end structure of the new high-pressure plunger pump, can solve the problem that the discharge check valve cannot be closed in time, the service life of the high-pressure reciprocating pump is affected, and the response of the discharge valve plate is inconsistent. Timely and other issues, to achieve the effect of sufficient opening and closing characteristics, saving materials, and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

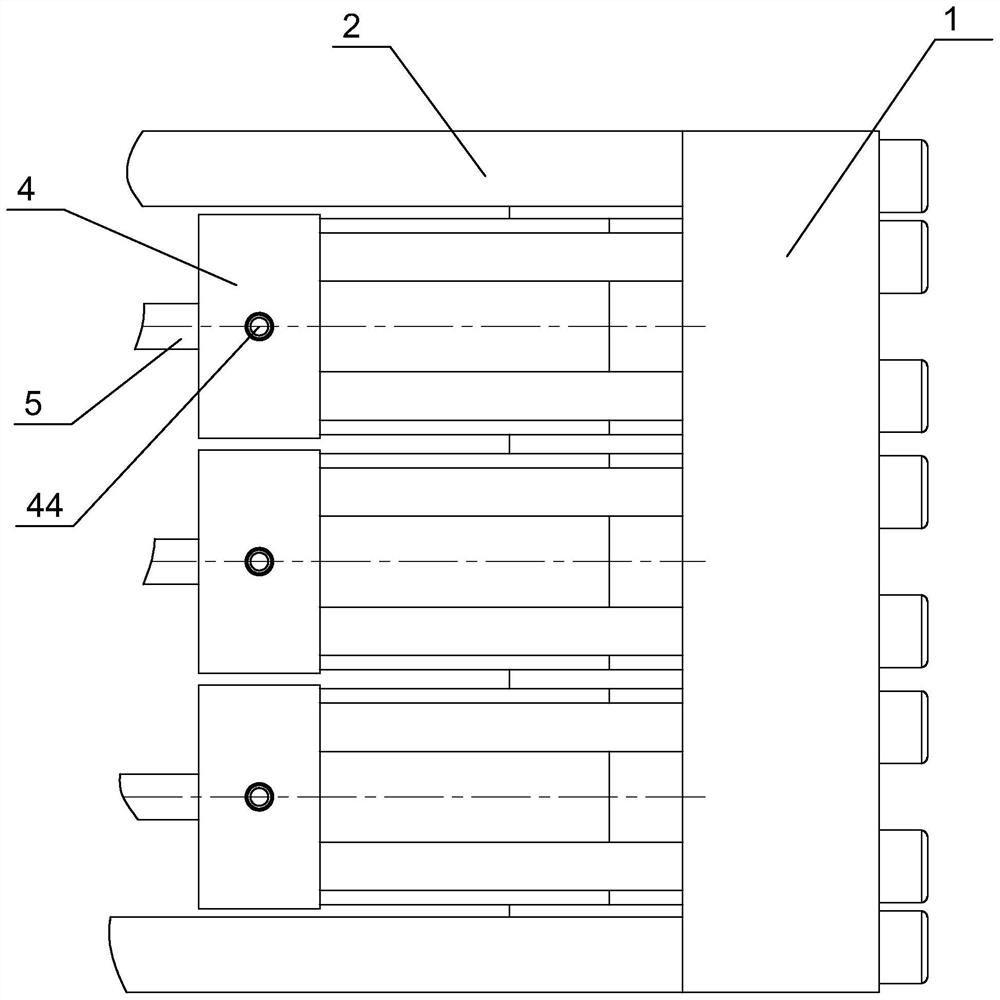

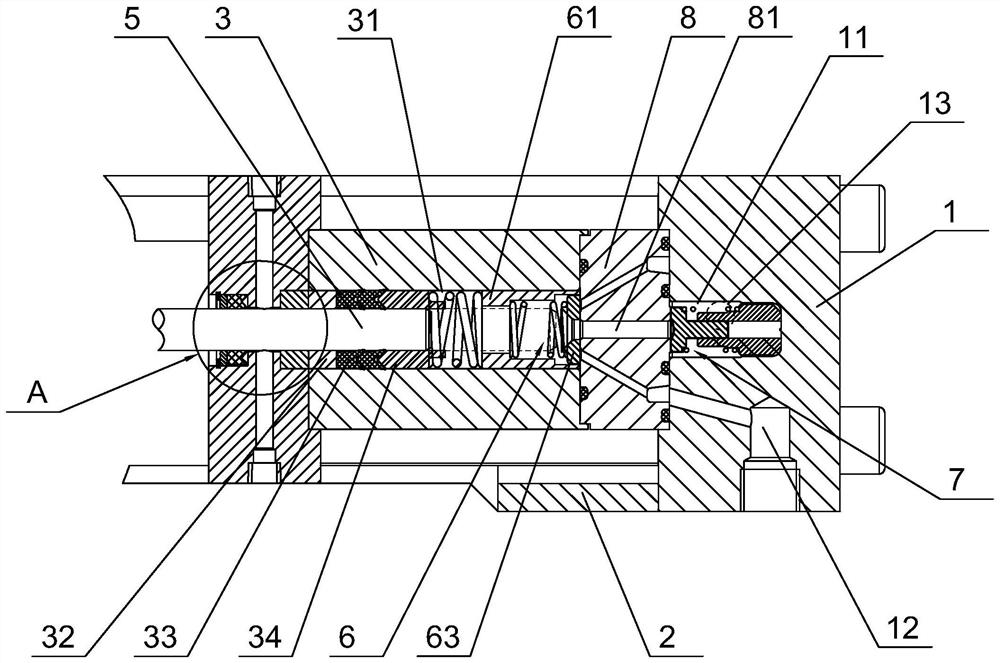

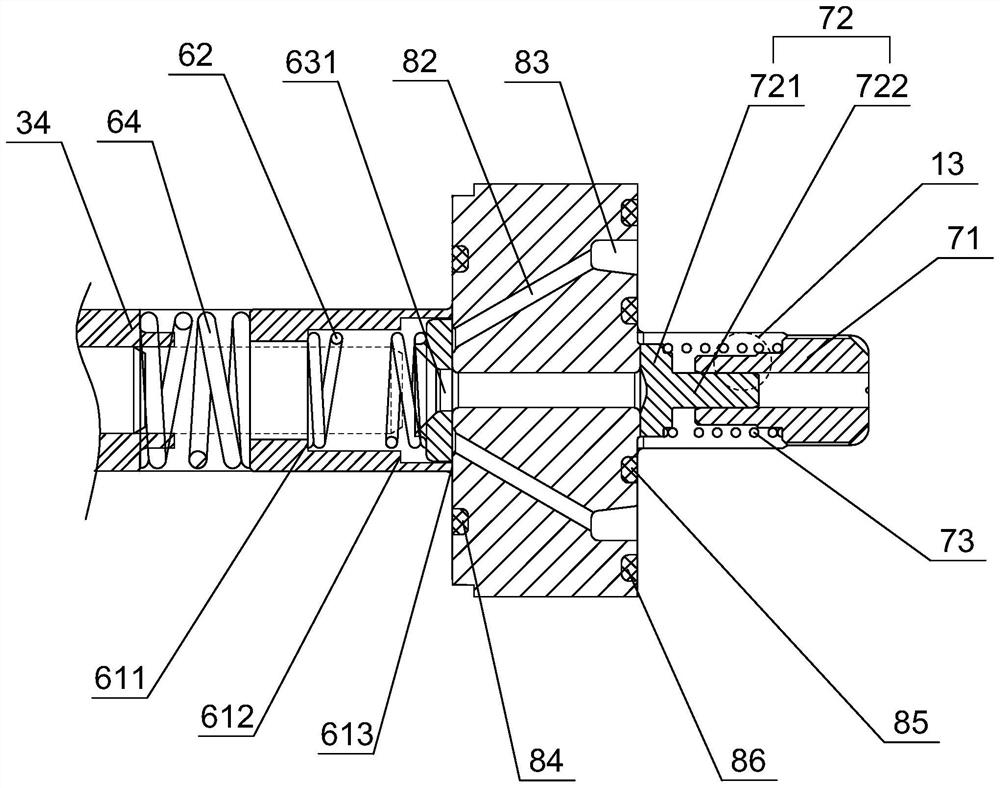

[0058] refer to figure 1 and figure 2 , including a bracket 2, a pump head 1, a plunger 5 and a low-pressure water seal 4, the pump head 1 and the low-pressure water seal 4 are respectively fixed at both ends of the bracket 2. The bracket 2 is an integral bracket, and the bracket 2 is provided with three sets of stuffing boxes 3 and three sets of valve group assemblies. The valve group assembly includes a liquid inlet check valve 6, a liquid discharge check valve 7, and a liquid inlet and discharge valve body 8. The pump head 1 is provided with a liquid discharge chamber 11, and the liquid discharge check valve 7 is located in the liquid discharge chamber 11. Inside, the stuffing box 3 is provided with a liquid inlet chamber 31, and the liquid inlet check valve 6 is arranged in the liquid inlet chamber 31, and the liquid inlet check valve 6 and the liquid discharge check valve 7 are located on the same axis. The liquid inlet and discharge valve body is arranged between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com