Full-automatic real-time sampling system and method for calorific value instrument in coking industry

A technology of real-time sampling and calorific value meter, which is applied in the direction of sampling device and material thermal development, can solve the problems of unable to meet the real-time control requirements, high installation site requirements, and affecting coking production, etc., to achieve automatic switching and automatic control, Realize fully automatic unmanned control and ensure the effect of safe and fully automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

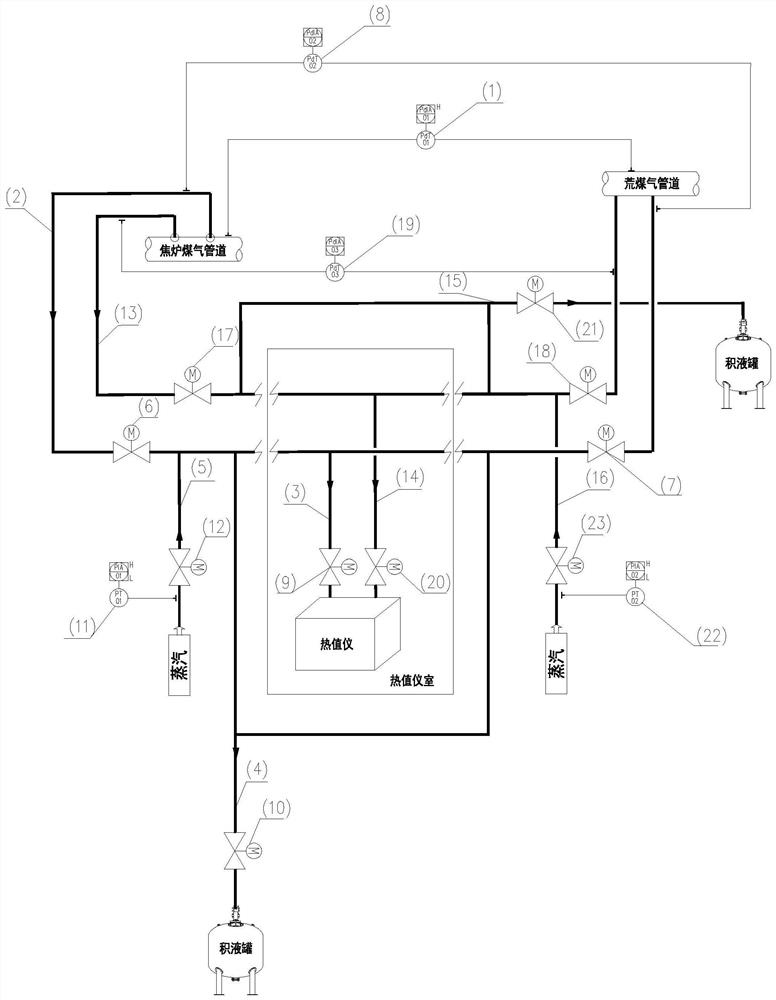

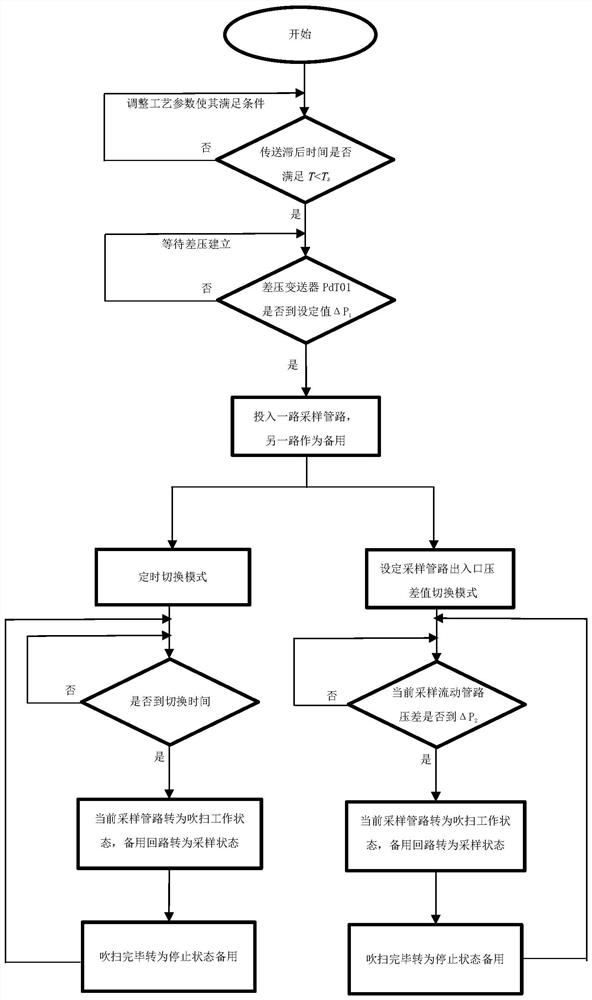

[0039] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] like figure 1 As shown, a real-time sampling system for a calorific value instrument in the coking industry includes a coke oven gas pipeline, a raw gas pipeline, a calorific value instrument, a sampling pipeline, and the first differential pressure transmitter PdT01 (1); the first differential pressure transmitter The device PdT01 (1) is installed on the differential pressure detection pipeline between the coke oven gas pipeline and the raw gas pipeline, and is used to detect the pressure difference between the coke oven gas pipeline and the raw gas pipeline.

[0041] The sampling pipeline includes two sampling pipelines: sampling pipeline A and sampling pipeline B. The two sampling pipelines have the same structure and are redundant with each other. One is in the sampling working state and the other is in the purging stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com