Performance detection equipment of motor controller and detection method thereof

A motor controller and detection equipment technology, applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve the problems of single function of detection equipment, affecting detection effect and accuracy, and low efficiency, so as to improve detection effect and accuracy, Replacement and wiring are simple and convenient, and the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

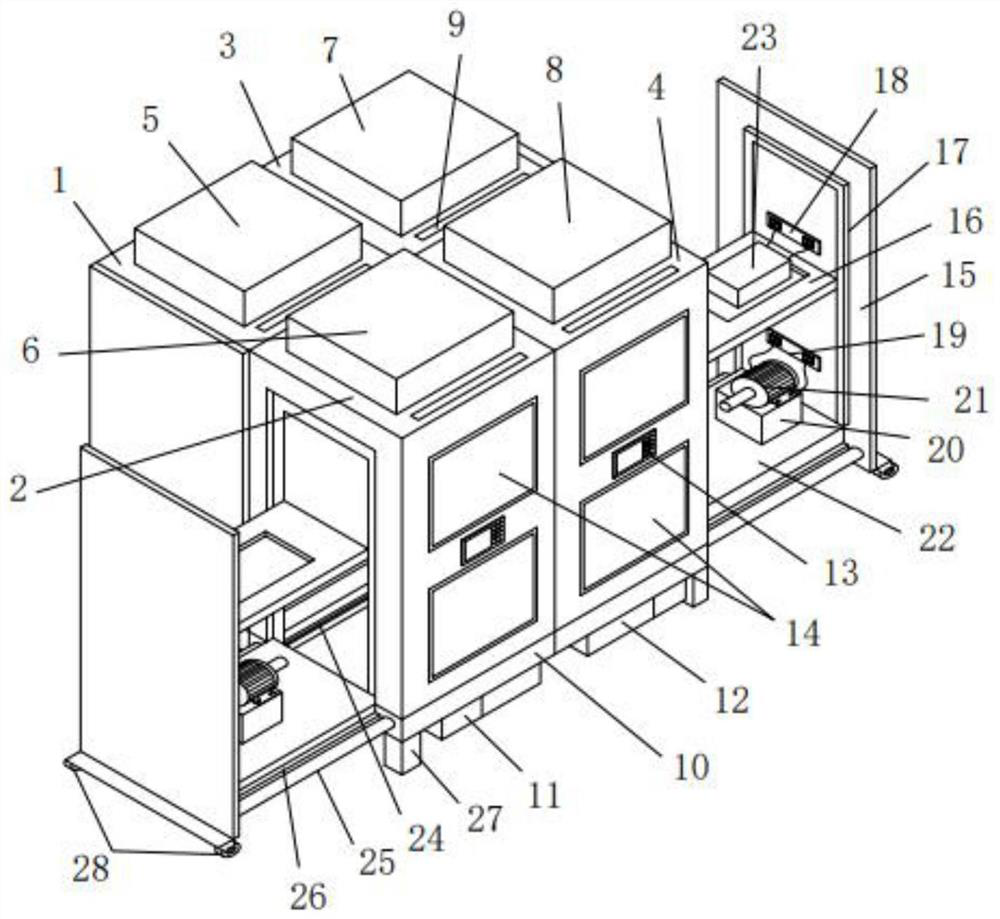

[0025] Example: see figure 1 , the present invention provides a technical solution: an electromagnetic compatibility performance testing device for a motor controller, including a detection box A1, a detection box B2, a detection box C3 and a detection box D4, and a harmonic current tester is installed on the top of the detection box A1 5. The lightning surge tester 6 is installed on the top of the test box B2, the electrical fast transient burst tester 7 is installed on the top of the test box C3, the damped oscillatory wave tester 8 is installed on the top of the test box D4, and the test box A1 , detection box B2, detection box C3 and both sides of the bottom of the detection box D4 are equipped with a base 10, the inside of the base 10 is equipped with a hydraulic cylinder 25, one end of the hydraulic cylinder 25 is equipped with a detection box door 15, and one side of the detection box door 15 A motor controller detection board 16 is installed, and the top of the motor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com