Vacuum transmitter monitoring and management method

A technology for monitoring and management of transmitters, applied in the field of transmitters, can solve problems such as waste of resources, and achieve the effect of improving use efficiency and achieving reliability prediction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

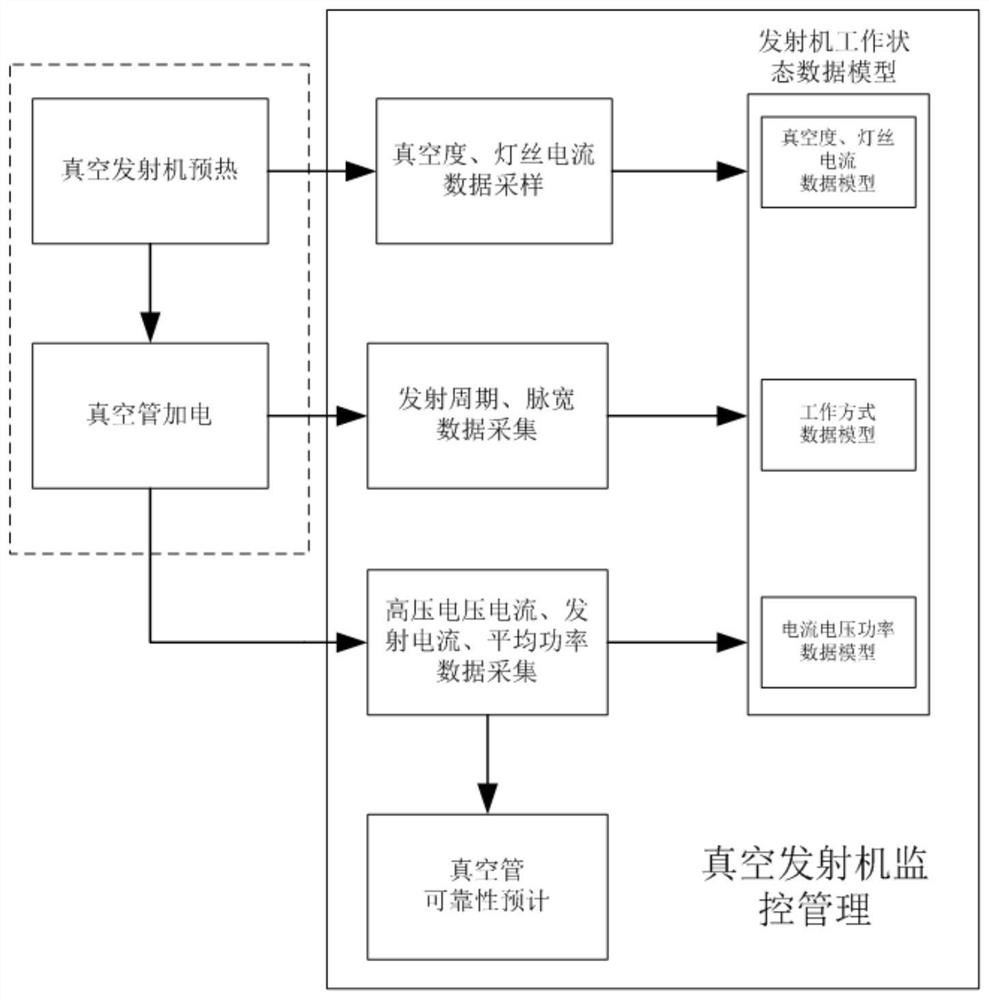

[0021] In order to verify the feasibility of the vacuum tube transmitter monitoring and management method, a radar vacuum tube transmitter is taken as an example to build a transmitter working data model.

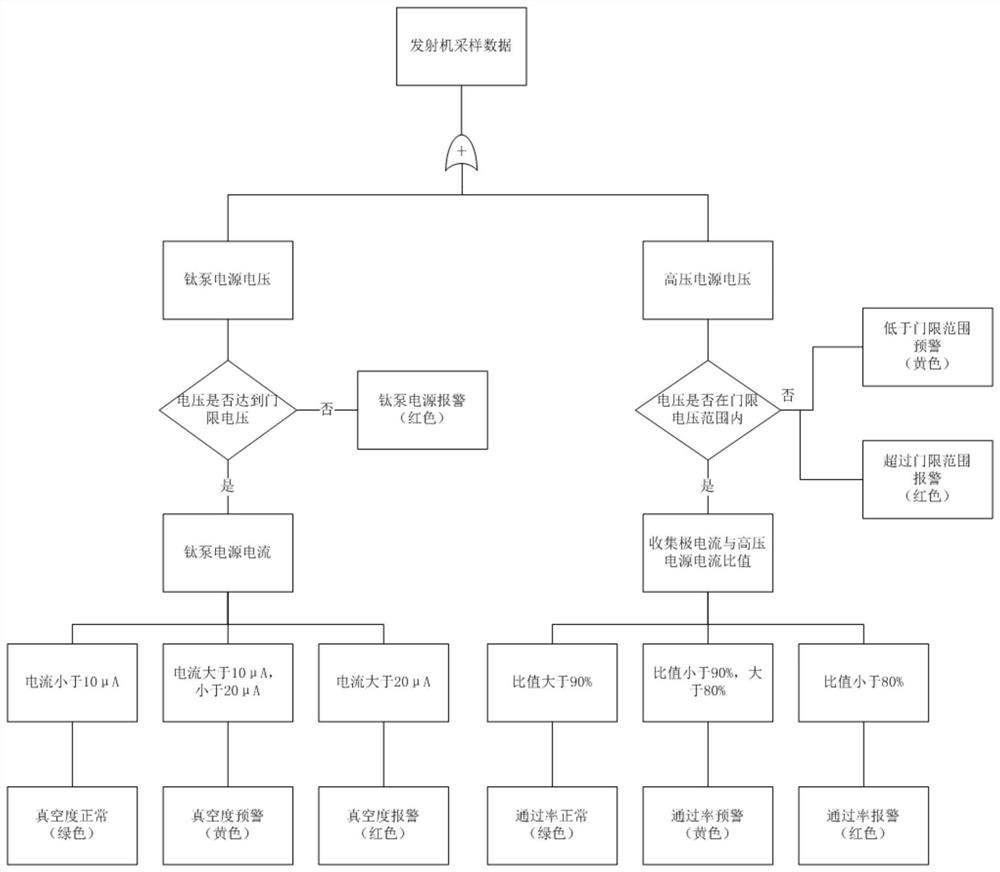

[0022] Step 1. Construct the data model of the normal working state of the vacuum tube transmitter. The vacuum tube of the transmitter requires a titanium pump voltage of 3kV, a titanium pump current of 0, and a filament current of 2.80A (determined by the vacuum tube itself). The typical working mode of the transmitter: the period is XμS, the pulse width is YμS, and the duty cycle is Y / X=δ. The transmitter voltage and current parameters corresponding to this working mode are as follows: high voltage power supply voltage 27.5kV, high voltage power supply current (I 总 )200mA, collector current (I 收 )180mA, tube body current (I 管 ) 20mA, average output power 900W.

[0023] So the transmitter working data model:

[0024] Vacuum degree of vacuum tube: Titanium pump voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com