Few-harmonic consequent-pole hub motor

An in-wheel motor, alternating pole technology, applied in electromechanical devices, electrical components, electric components, etc., can solve the problem of asymmetric air gap magnetic density of alternating pole permanent magnet motor, save the amount of permanent magnet, wide application prospect, simplify Effects of machining and assembly processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

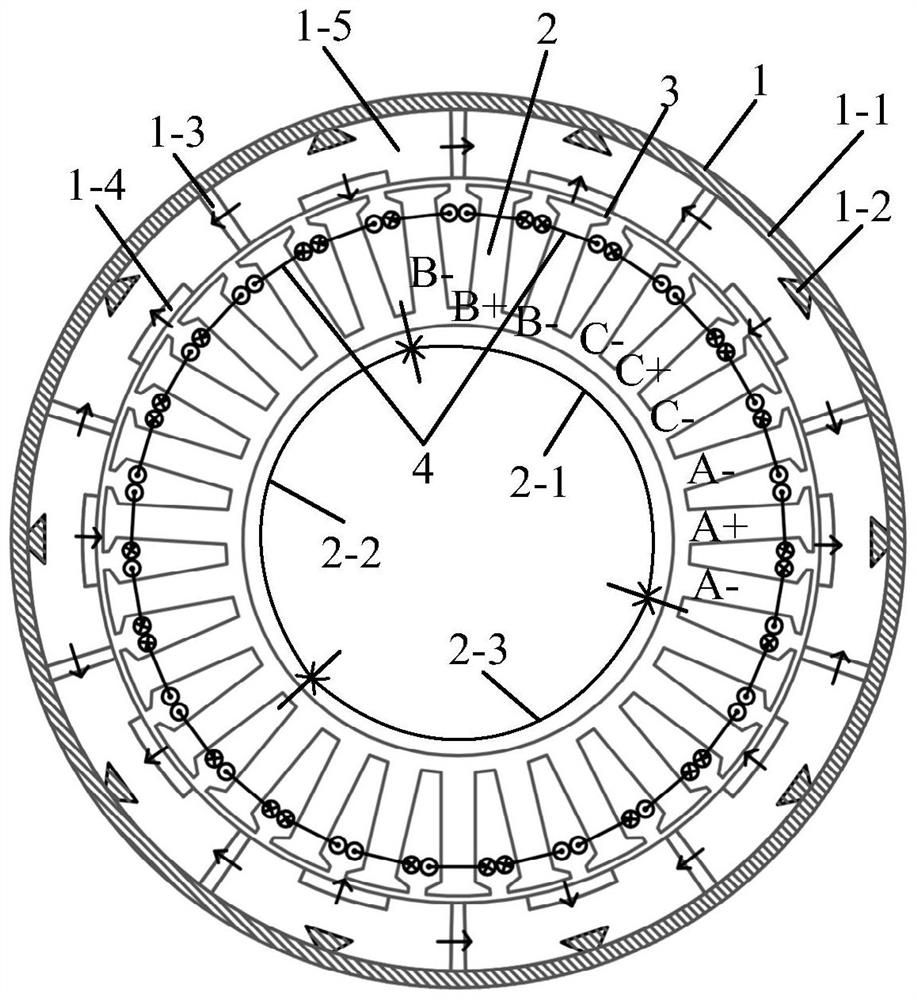

[0021] The present invention designs a hub motor with less harmonics alternating poles, such as figure 1 As shown, it includes an inner stator 2 composed of three 9-tooth stator modules 2-1, 2-2 and 2-3, and an outer permanent magnet rotor 1, and the three 9-tooth stator modules are evenly distributed in the circumferential direction. The outer permanent magnet rotor 1 includes a non-magnetically conductive component 1-1, a magnetically permeable component 1-5, a circumferentially magnetized permanent magnet 1-3 and a radially magnetized permanent magnet 1-4. The non-magnetically conductive component 1-1 and the magnetically permeable component 1-5 are fastened together through dovetail grooves / dovetail teeth 1-2. An independent air gap 3 is formed between the inner stator 2 and the outer permanent magnet rotor 1 . Circumferentially magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com