Composite filling material for exciting curing of coal gangue, and preparation method thereof

A technology for filling materials and coal gangue, which is applied in the field of composite filling materials that stimulate coal gangue solidification and its preparation, can solve the problems of low utilization rate of gangue, labor-intensive cleaning, high pumping resistance, etc., and achieve adjustable and controllable filling parameters , improve utilization efficiency, and achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

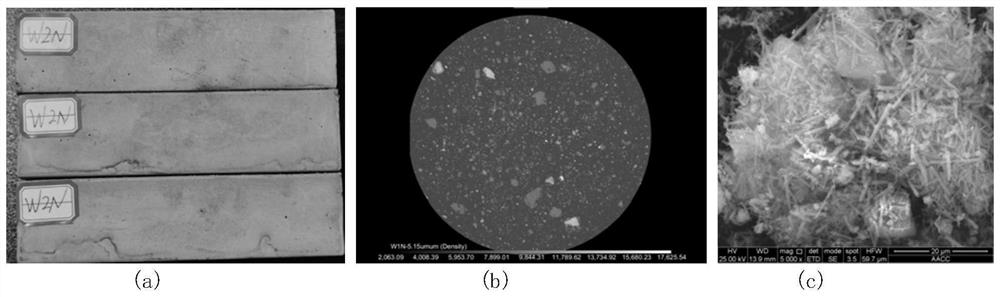

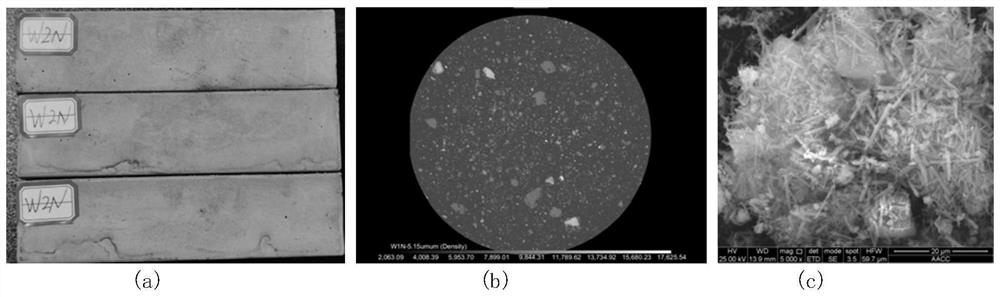

Image

Examples

Embodiment 1

[0039] The composite filling material that stimulates coal gangue solidification described in this example has a water-solid ratio of 1:1+powder-solid ratio of 2:1+powder-particle ratio of 1:1. Mass composition, wherein in parts by mass, material A gangue slurry: 2 parts of gangue particles, 2 parts of gangue powder, 1 part of composite excitation curing agent A, 1 part of water; material B gangue slurry: 2 parts of gangue particles, 2 parts of

[0040] Gangue powder, 1 part of compound excitation curing agent B, 1 part of water.

[0041] Based on the preparation method of the composite filling material that stimulates coal gangue solidification, the steps are as follows:

[0042] (1) Coal gangue is crushed in two stages to generate gangue particles with a particle size of 0.5-10mm;

[0043] (2) Get part of the gangue particles and further generate gangue powder through ball mill grinding;

[0044] (3) Get 2 parts of gangue granules, 2 parts of gangue powder, 1 part of compo...

Embodiment 2

[0048] The composite filling material that stimulates coal gangue solidification described in this embodiment has a water-solid ratio of 2:1+powder-solid ratio of 1:1+powder-to-particle ratio of 2:1, and the formula is as follows: first material gangue slurry and second material gangue slurry Mass composition, wherein in parts by mass, material A gangue slurry: 1 part of gangue particles, 2 parts of gangue powder, 2 parts of composite excitation curing agent A, 4 parts of water; material B gangue slurry: 1 part of gangue particles, 2 parts of

[0049] Gangue powder, 2 parts of compound excitation curing agent B, 4 parts of water.

[0050] Based on the preparation method of the composite filling material that stimulates coal gangue solidification, the steps are as follows:

[0051] (1) Coal gangue is crushed in two stages to generate gangue particles with a particle size of 0.5-10mm;

[0052] (2) Get part of the gangue particles and further generate gangue powder through ball ...

Embodiment 3

[0057] The composite filling material that stimulates coal gangue solidification described in this embodiment has a water-solid ratio of 4:1+powder-solid ratio of 1:1+powder-particle ratio of 3:1, and the formula is as follows: Composition, wherein in terms of parts by mass, A material gangue slurry: 1 part of gangue particles, 3 parts of gangue powder, 3 parts of composite excitation curing agent A, 12 parts of water; B material gangue slurry: 1 part of gangue particles, 3 parts of gangue powder , 3 parts of compound excitation curing agent B material, 12 parts of water.

[0058] Based on the preparation method of the composite filling material that stimulates coal gangue solidification, the steps are as follows:

[0059] (1) Coal gangue is crushed in two stages to generate gangue particles with a particle size of 0.5-10mm;

[0060] (2) Get part of the gangue particles and further generate gangue powder through ball mill grinding;

[0061] (3) Get 1 part of gangue granules,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com