An environment-friendly two-for-one twisted yarn to produce s-shaped conductor structure

An environmentally friendly, twisting technology, used in textiles and papermaking, continuous winding spinning machines, spinning machines, etc., can solve the problems of position deviation, affecting normal operation, yarn instability, etc., to improve the tightness The effect of high degree, avoid flying around, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

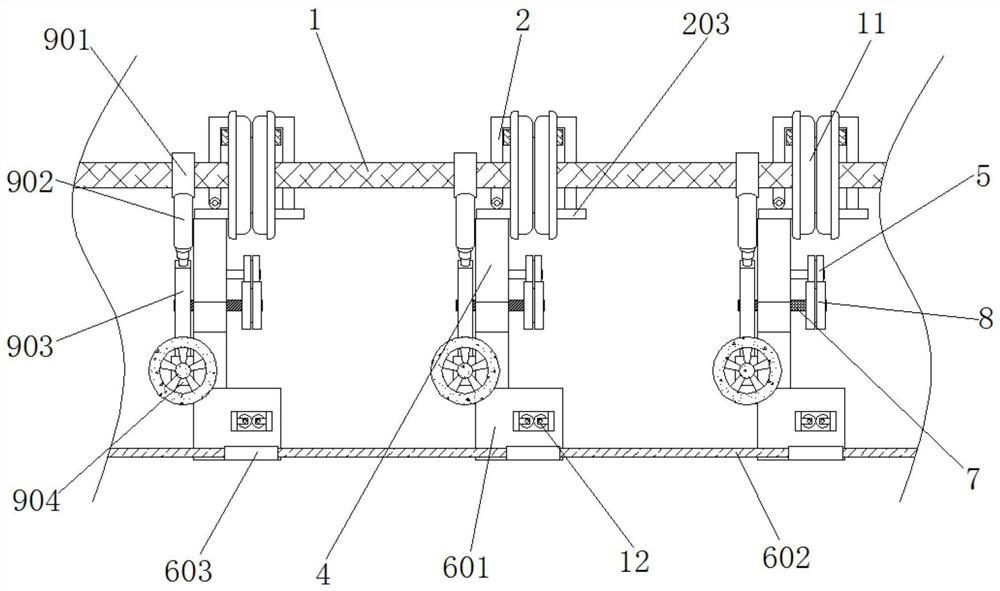

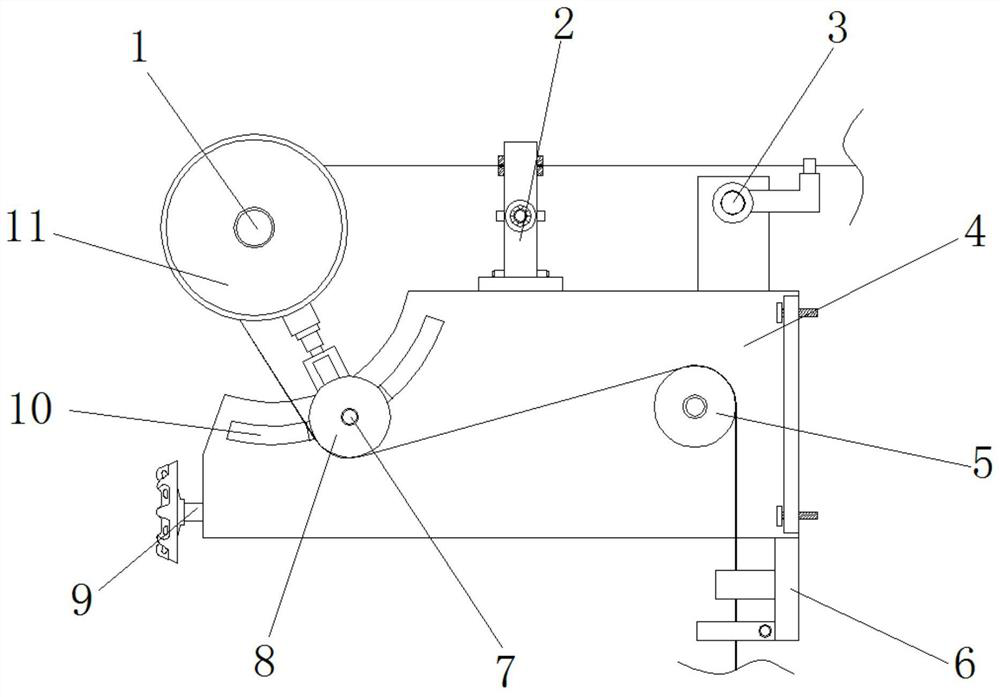

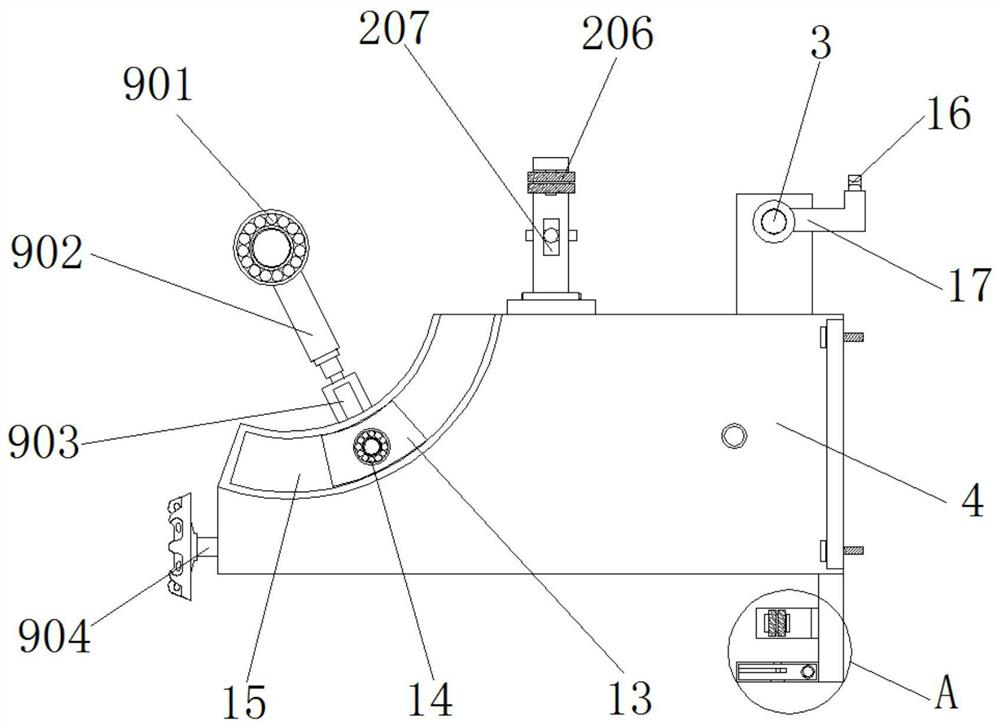

[0038] Example 1, as Figure 1-7 As shown in the figure, when the double twister starts to operate, the spool continuously winds the yarn, and the moving shaft 3 continuously moves left and right with the third thread inlet 16 and the L-shaped mounting frame 17, so that the yarn can be evenly It is wound on the outside of the reel, and during the left and right reciprocating movement of the moving shaft 3, the yarn located between the two sets of fourth wire pulleys 206 is constantly in close contact with the grooves of the two sets of fourth wire pulleys 206, and drives the The four wire pulleys 206 rotate, and when the textile thread enters the inside of the dedusting bin 603 and is twisted into a yarn, the textile thread is constantly rubbed against the bottom of the inner wall of the second thread inlet hole 606 due to the force generated by the rotation. At the same time, the inside of the suction pipe 602 is in a negative pressure state through an external suction device...

Embodiment 2

[0039] Example 2, as Figure 1-4 As shown, when the tightness of the yarn needs to be adjusted, the long threaded rod 904 is manually rotated to force the female threaded block 905 to move on the long threaded rod 904. If the female threaded block 905 moves to the end away from the arc-shaped chute 15, Then the limit bar frame 903 pushes the rotating shaft 7 and the arc slider 13 to move in the same direction, the rotating shaft 7 slides inside the limit bar frame 903, and the lift rod 902 is gradually extended, and the arc slider 13 Moving inside the arc-shaped chute 15 will also bring the third wire pulley 8 closer to the end of the second wire pulley 5, so that the actual distance of the yarn between the second wire pulley 5 and the guide plate 11 is shortened, and vice versa. The actual distance of the yarn between the second guide wheel 5 and the guide disc 11 also improves the tightness of the yarn, the operation is simple, and the tightness of the yarn after adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com