Toilet flushing control method and flushing toilet

A control method and toilet technology, applied in the field of bathroom, can solve the problems of increasing the manufacturing difficulty and cost of a ceramic seat, the effect of pre-wetting is not large, and the flow of pre-wetting is large, so as to ensure the integrity, the structure is diverse, and the flushing area is increased. and strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

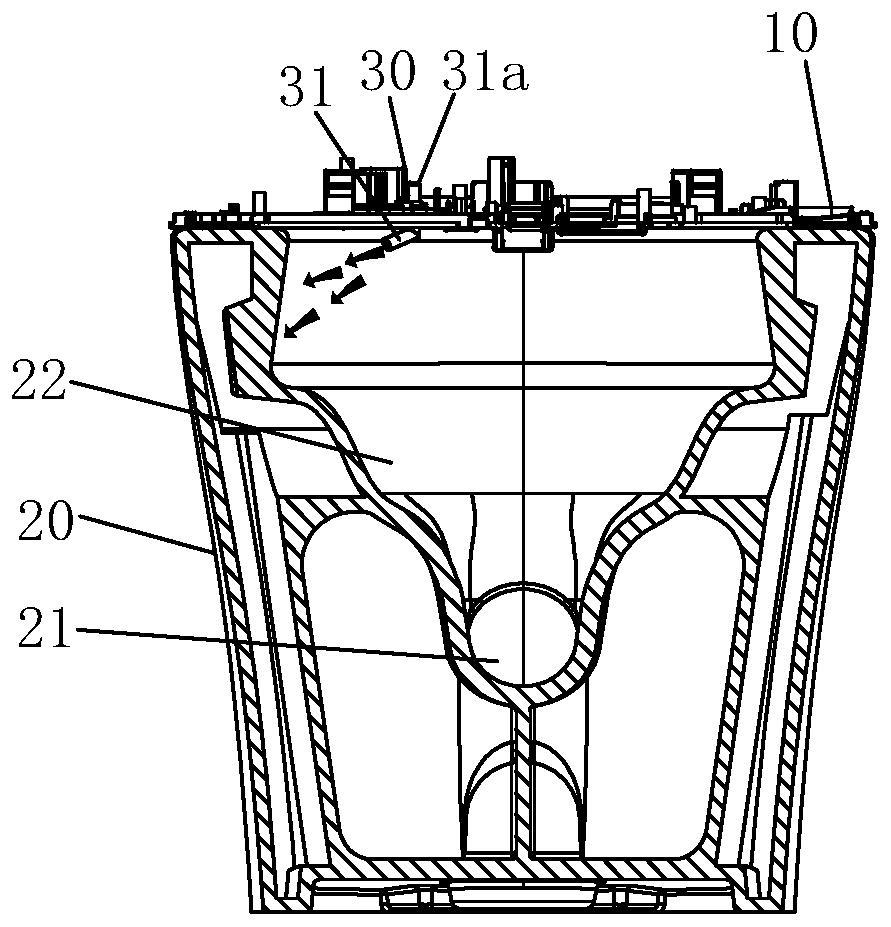

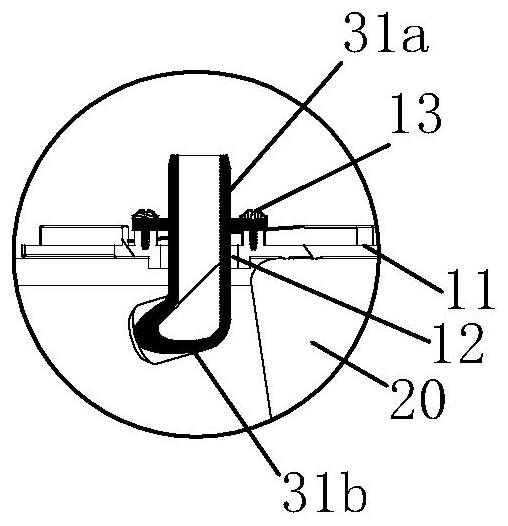

[0046]A method for controlling flushing of a toilet, in which a pressure regulating module 40 and at least one injection assembly 30 are arranged on a cover body 10 . The jetting end of the jetting assembly 30 is facing the side wall of the urinal 21 . The pressure regulating module 40 communicates with the water inlet end of the spray head 31 to adjust the water pressure, that is, the pressure regulating module 40 can adjust the pressure and flow rate of the water sprayed by the spray assembly 30 .

[0047] The concrete steps of the inventive method are as follows:

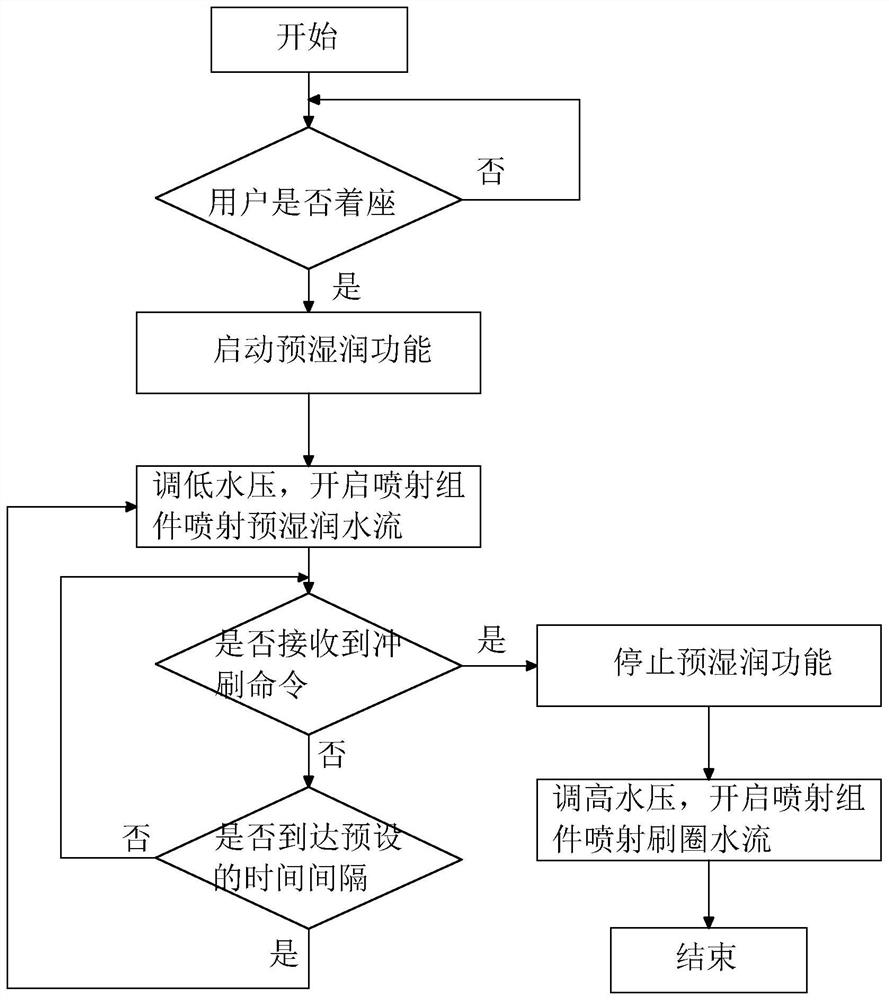

[0048] see figure 1 , detect whether the user is seated, when it is detected that the user is seated, start the pre-humidification function, control the pressure regulating module 40 to lower the water pressure, and at the same time turn on the spray assembly 30 to spray at least one pre-wet water flow according to the preset time interval. The duration of each pre-wet water flow can also be set according to ne...

Embodiment 2

[0062] see figure 1 , Figure 5-Figure 6 , a toilet flushing control method and a flushing toilet, its main features are the same as the first embodiment, the difference is: the spray head 31 and the base 11 are rotatably connected. Specifically, the spray assembly 30 is further provided with an adapter 31c, through which the spray head 31 is connected. The adapter 31c is fixed on the cover 10 and one end thereof is connected to the connecting pipe 33; the spray head 31 is rotatably connected and communicated with the adapter 31c. That is, the connecting portion 31a of the injection head 31 is inserted into the adapter 31c, and it can rotate relative to the adapter 31c within a certain angle range, and its angle relative to the inner wall of the seat body 20 can be adjusted to meet the requirements of different injection angles. In order to ensure the sealing performance between the spray head 31 and the adapter 31c, at least one sealing ring is provided between the spray he...

Embodiment 3

[0067] see figure 1 , Figure 7-Figure 9 , a toilet flushing control method and a flushing toilet, its main features are the same as the first embodiment, the difference is: the spray head 31 and the base 11 are rotatably connected. Specifically, the spraying assembly 30 also includes a casing 34 and a rotating drive assembly 35; the casing 34 is fixed on the base 11 and is provided with a water inlet 36c. One end of the spray head 31 is rotatably connected to the base 11 and communicated with the water inlet 36c, and the other end is a spray end facing the side wall of the urinal 21 .

[0068] The rotation driving assembly 35 is connected to drive the spray head 31 to rotate so that the spray end sprays water towards the side wall of the urinal 21 . The rotating drive assembly 35 can be driven by gears, and includes a motor 35a, a driving wheel 35b and a driven wheel 35c. The motor 35a is connected to drive the driving wheel 35b to rotate. Wherein, the motor 35 a is fixed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap