Tobacco dryer, operation control method and system thereof and readable storage medium

A technology of operation control and drying system, applied in dryers, tobacco drying, tobacco and other directions, can solve the problem of frequent start and stop of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

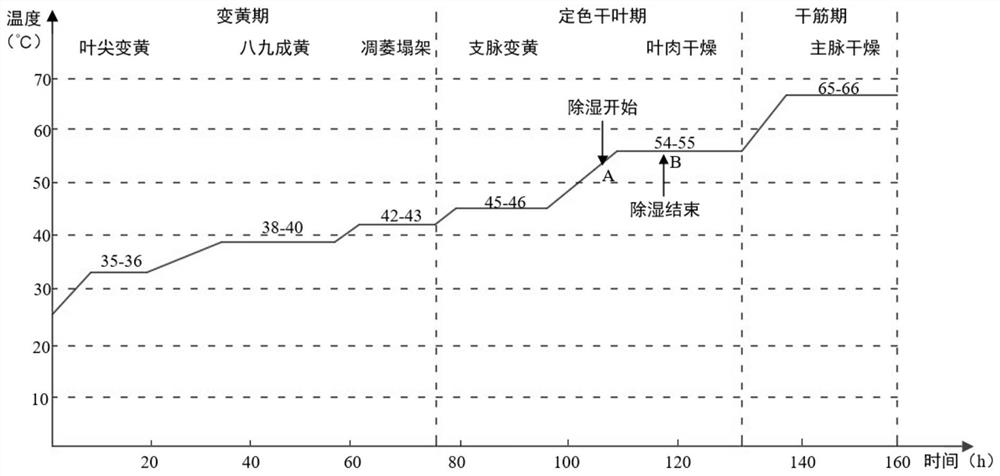

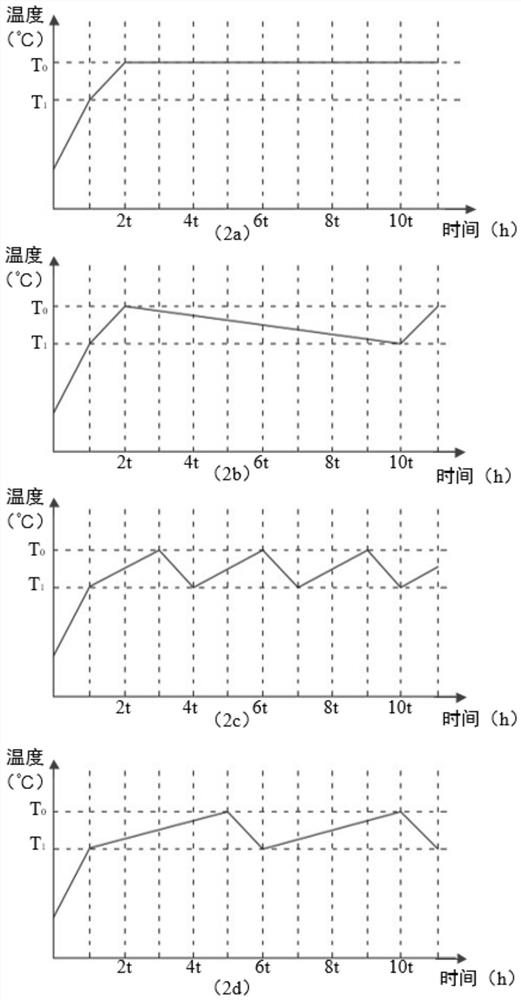

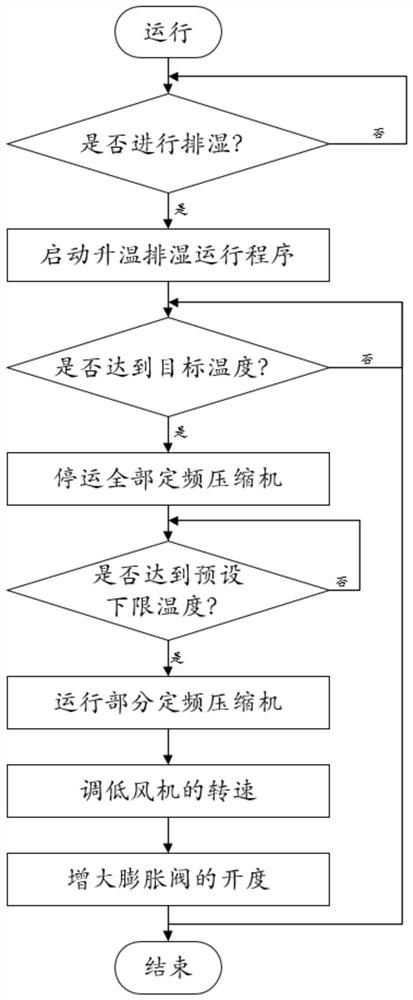

Examples

Embodiment Construction

[0039] First, it is to be noted that the following embodiments are intended to illustrate the technical principles of the present invention, and are not intended to limit the scope of the invention. In order to better illustrate the invention, numerous specific details are given in the specific embodiments below. Those skilled in the art will appreciate that there is no specific details, and the present invention can also be implemented.

[0040] In the description of the invention, the term "first", "second" is used only for the purpose, and cannot be understood as an indication or implies relative importance.

[0041] The tobacco dryer provided in the embodiment of the present invention is a dual-fixed frequency compressor system, which is configured with two independently running fixed frequency compressors for a baking room. The input roast room can be adjusted by adjusting the number of fixed-frequency compressors. The heat. Each fixed frequency compressor is connected to a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com