Continuous vacuum heating equipment

A technology of vacuum heating and equipment, applied in lighting and heating equipment, furnace types, furnaces, etc., can solve the problems of prolonged process time and unable to improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

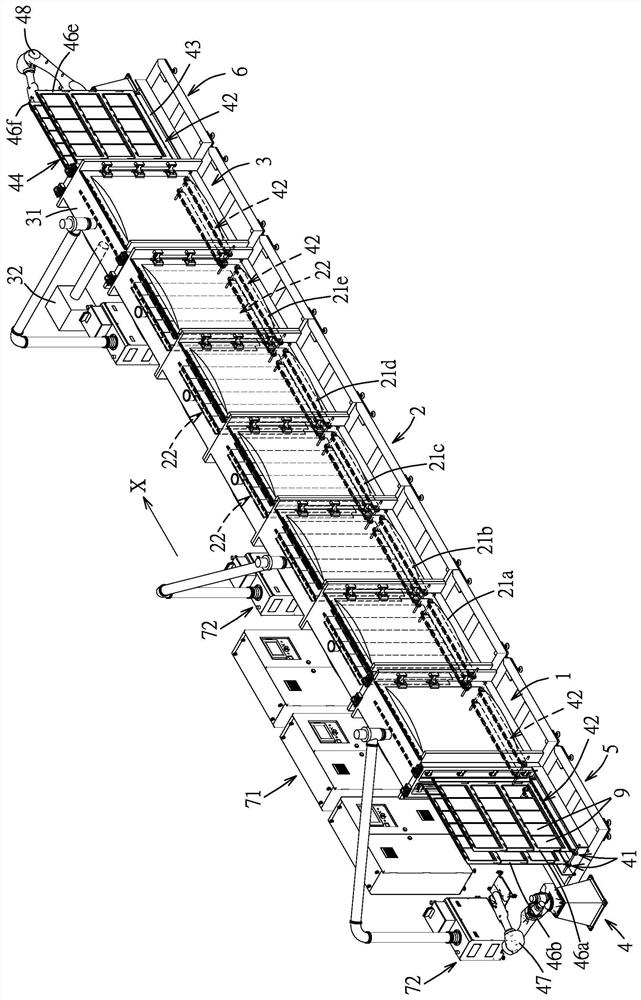

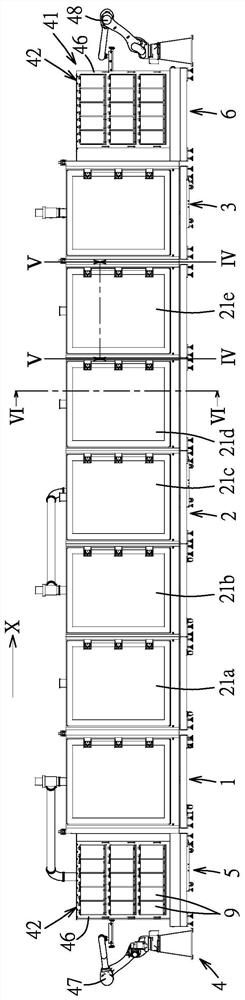

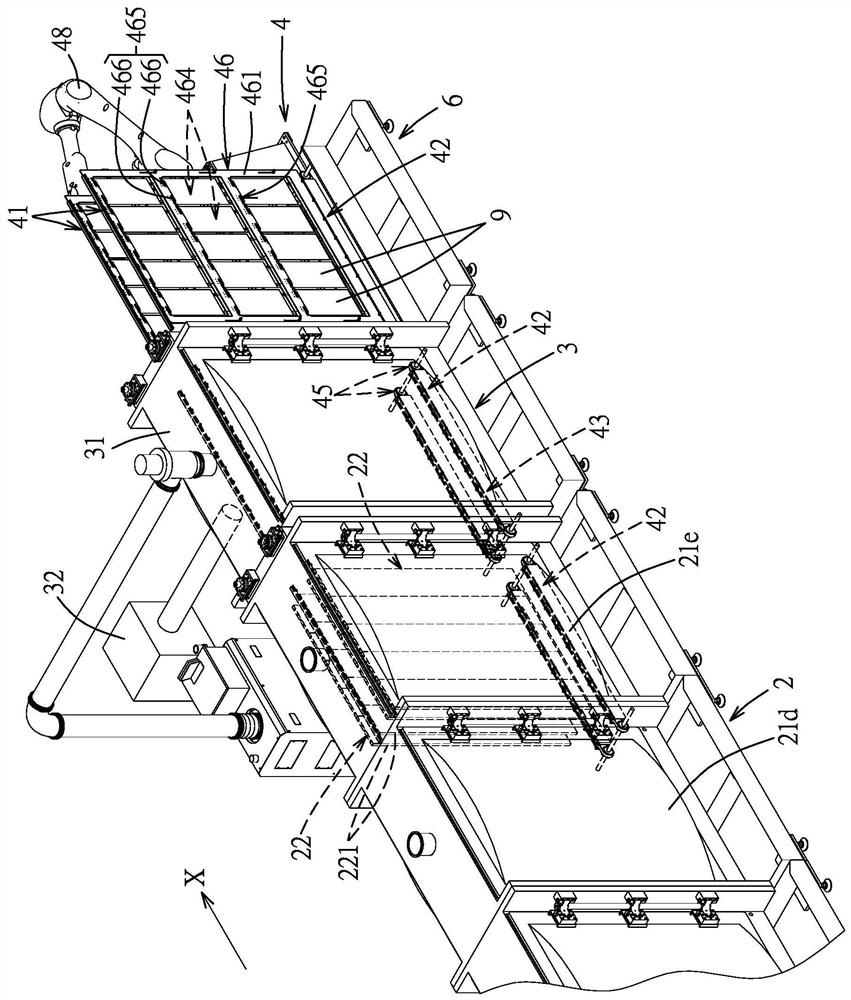

[0023] refer to Figure 1 to Figure 3 , is an embodiment of the continuous vacuum heating equipment of the present invention. The continuous vacuum heating device is suitable for heat treatment of at least one circuit board 9 . The circuit board 9 can be coated with a circuit layer on one or both sides. In this embodiment, the number of the circuit boards 9 is taken as an example to express that the circuit boards 9 can be heated in batches. However, the number of the circuit boards 9 may also be only one, and is not limited to a specific number. The continuous vacuum heating equipment includes a feed cabin 1 , a vacuum heating cabin 2 , a discharge cabin 3 , a conveying system 4 , a feed temporary storage area 5 and a discharge temporary storage area 6 .

[0024] The feed compartment 1 is suitable for the circuit board 9 to be moved into it from the outside, and the internal pressure value can be controlled and adjusted. The vacuum heating cabin 2 communicates with the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com