Method for calibrating optical axis and pupil of light beam tracking and pointing equipment

An optical axis and pupil technology, applied in the field of photoelectric tracking and aiming imaging, can solve the problems of large detection system space, high cost, real-time equipment aiming accuracy, poor stability, etc., achieve high beam reduction ratio, long focal length, and ensure tracking Effect of Accuracy and Aiming Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] All features disclosed in all embodiments in this specification, or steps in all implicitly disclosed methods or processes, except for mutually exclusive features and / or steps, can be combined and / or extended and replaced in any way.

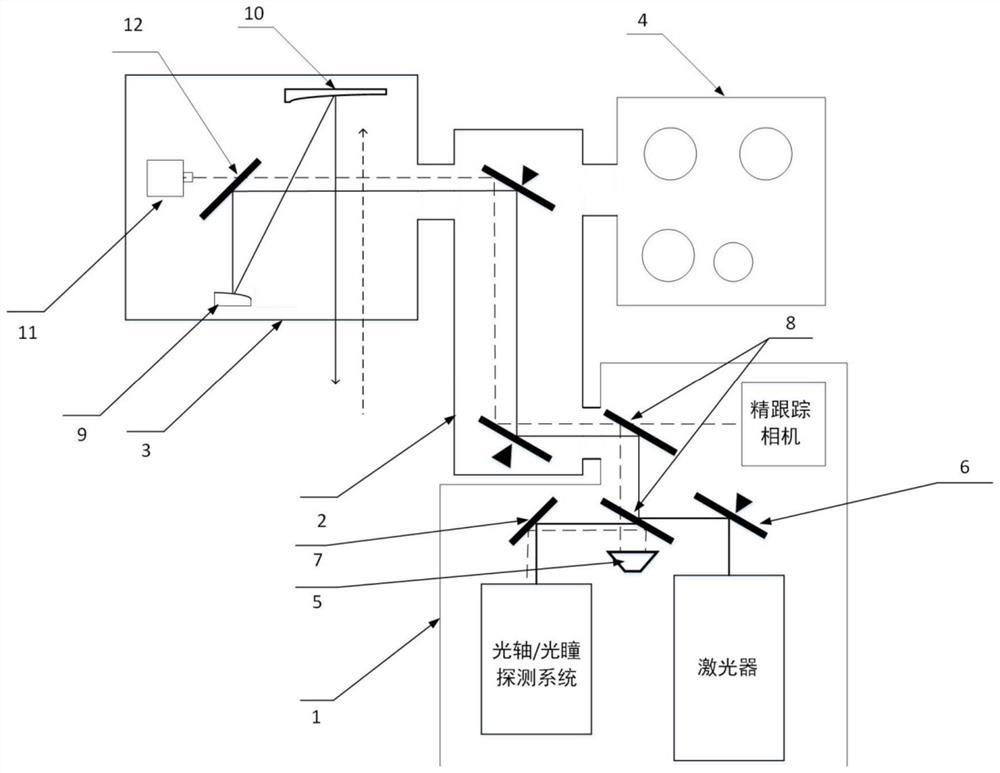

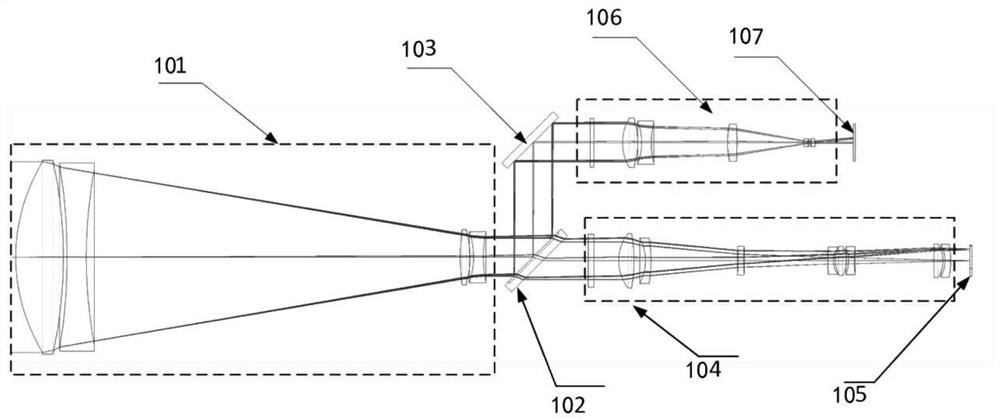

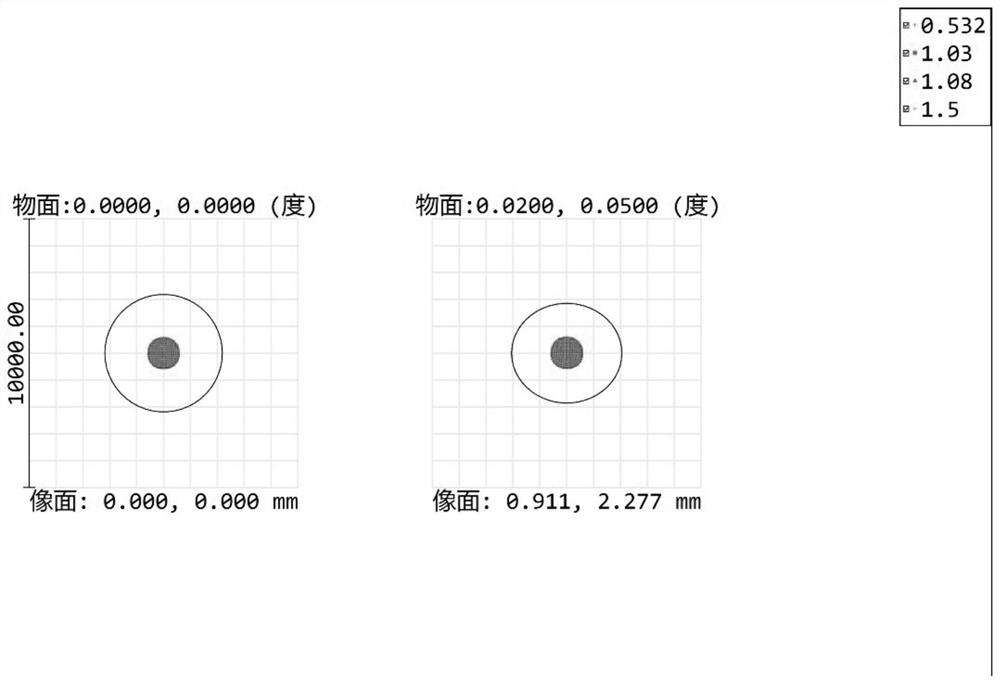

[0038] Such as Figure 1 to Figure 6 As shown, a method for optical axis pupil calibration of beam tracking equipment includes the steps of: imaging on the optical axis and pupil camera with reference light, making differences with the calibrated position and angle after imaging, and then controlling the adjustment The attitude of the fast mirror realizes the calibration of the imaging optical axis, the emitting optical axis and the mechanical axis of the turntable.

[0039] In an optional embodiment, substeps are included:

[0040] S1, control the rotation of the photoelectric turntable of the beam tracking equipment, and calibrate the optical axis and the mechanical axis of the photoelectric turntable;

[0041] S2, through the rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com