Gas turbine compressor blade field in-situ ultrasonic detection tool

An ultrasonic testing and gas turbine technology, which is applied to measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis, etc., can solve the complex shape of compressor blades, poor probe coupling, and detection problems and other problems to achieve the effect of improving probe coupling conditions and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

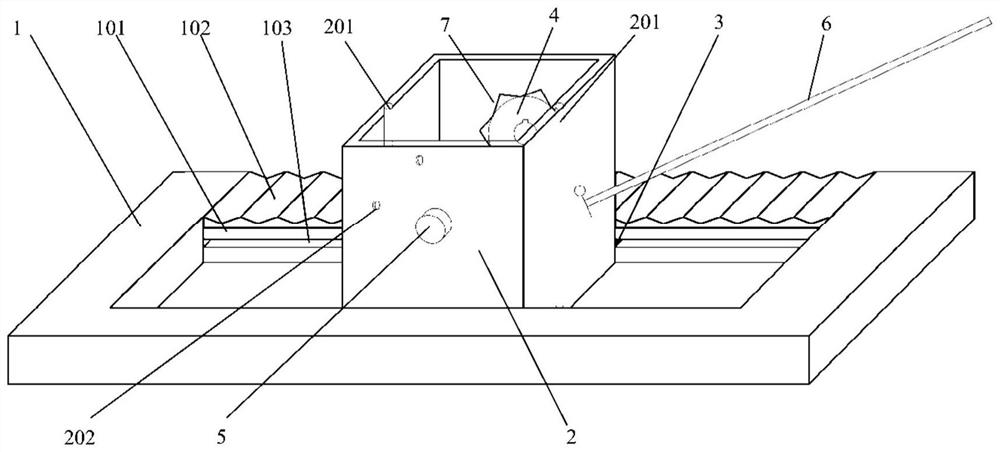

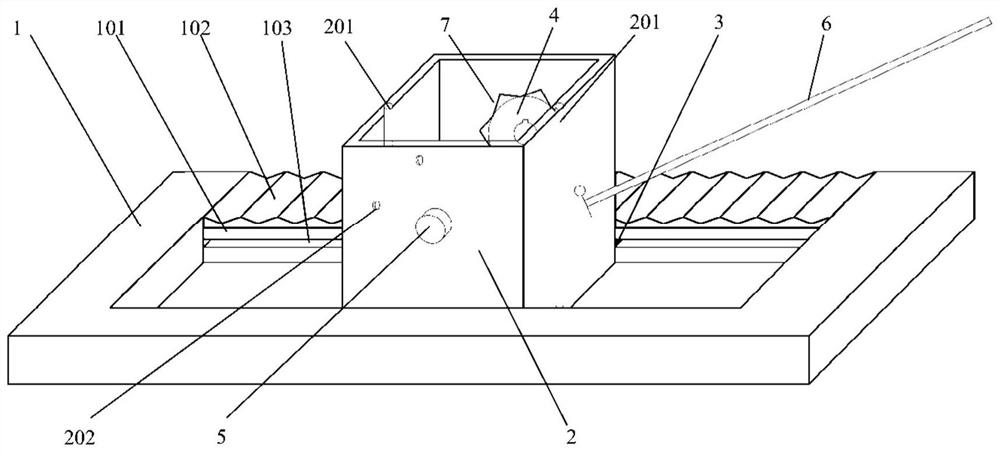

[0022] refer to figure 1 , a gas turbine compressor blade field in-situ ultrasonic detection tooling provided by the present invention is characterized in that it includes a base 1, a probe clamping device 2, a guide pin 3, an encoder 4, a ranging module 5 and a joystick 6 .

[0023] The base 1 includes a permanent magnet 101 and a toothed guide rail 102. The shape of the permanent magnet 101 is zigzag, and directly interacts with the surface of the blade to be tested.

[0024] The permanent magnet 101 is composed of 2 long sides and 2 short sides. The long side is perpendicular to the direction of the compressor blade body, and the short side is parallel to the direction of the compressor blade body. The width of the long side should not be less than 30mm, and the width of the short side should not Greater than 10 mm, the toothed guide rail 102 is embedded on the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com