Power transmission line maintenance ladder stand

A technology for transmission lines and ladders, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of high labor and physical consumption of maintenance operators, low operation safety factor, inconvenient use and portability, etc., and achieves safe operation of efficient transmission lines. Work risk, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

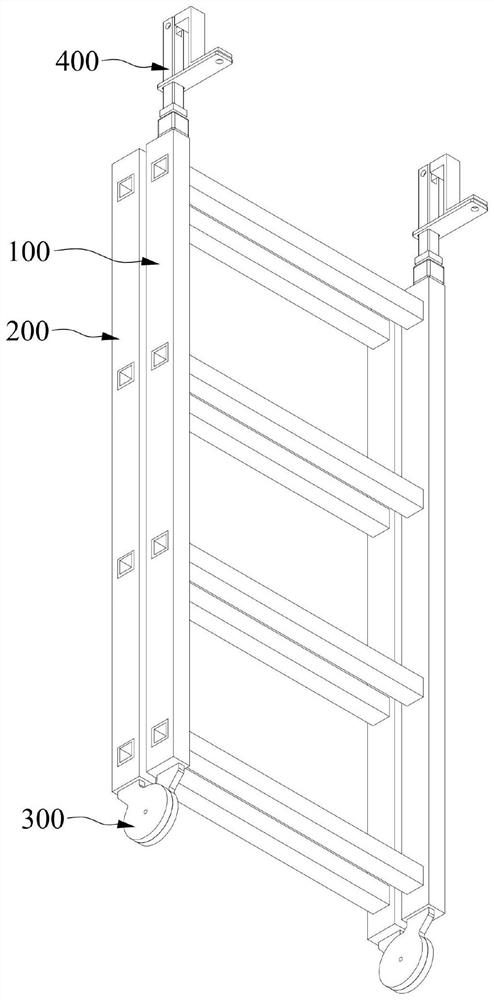

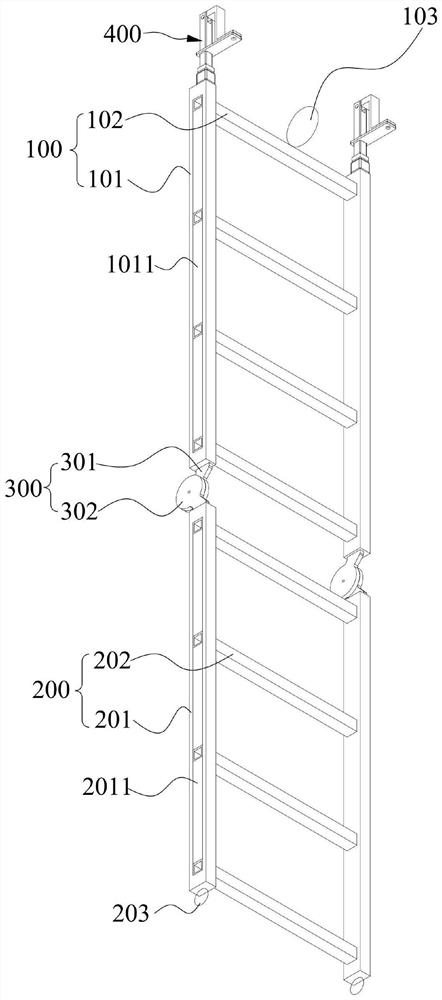

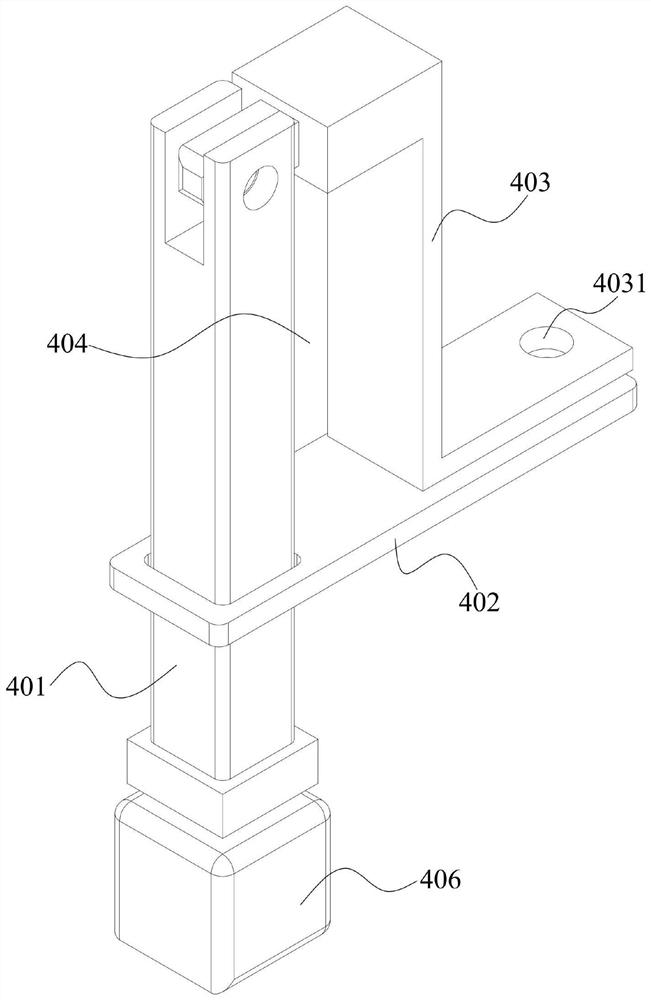

[0034] Such as Figure 1 to Figure 4As shown, this embodiment provides a power transmission line maintenance ladder, including a first ladder body 100, a second ladder body 200, a folding lock assembly 300 and a hook assembly 400, wherein one end of the folding lock assembly 300 is connected to the first One end of the ladder body 100 is connected, and the other end of the folding lock assembly 300 is connected with one end of the second ladder body 200. The hook assembly 400 includes a hook body 401, a hook positioning piece 402 and a hook lock 403. One end of the hook body 401 is connected to the second ladder body 200. A ladder body 100 is connected to one end away from the folding lock assembly 300, and the hook body 401 can swing to a desired angle relative to the first ladder body 100. One end of the hook positioning piece 402 is connected to the hook body 401, and one end of the hook lock 403 is connected to the hook body 401. The hook body 401 is rotatably connected aw...

Embodiment 2

[0045] This embodiment provides a power transmission line maintenance ladder. The difference between it and Embodiment 1 is that a first guide rail 1011 is provided on the side of the first vertical beam 101 facing away from the first cross beam 102 in this embodiment, and the second vertical beam The side of 201 facing away from the second beam 202 is provided with a second guide rail 2011 , the first guide rail 1011 can communicate with the second guide rail 2011 , and the slider can slide in the first guide rail 1011 and the second guide rail 2011 . By setting the first guide rail 1011 and the second guide rail 2011, when in use, the maintenance personnel are fastened to the slider by a rope, which can further ensure the safety of the maintenance personnel, and the hook on the hanging position can be stuck on the first guide rail 1011 And in the second guide rail 2011, further reducing the risk of falling of the transmission line maintenance ladder.

[0046] Other structure...

Embodiment 3

[0048] This embodiment provides a power transmission line maintenance ladder, which is different from Embodiment 1 in that a first rubber pad 407 is provided on the side of the hook body 401 close to the hook lock 403 , and the hook positioning piece 402 is close to the hook lock 403 One side is provided with a second rubber pad 408 . By arranging the first rubber pad 407 and the second rubber pad 408, the stability of the hook assembly 400 can be enhanced, the friction with the hanging position can be increased, the swing between the hook assembly 400 and the hanging position can be avoided, and insulation can also be played. Avoid the risk of electric shock for maintenance personnel.

[0049] Other structures of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com