Feeding system for glass bottle production

A feeding system and glass bottle technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of initial mold impact, lower production efficiency, and high speed, so as to reduce the risk of damage, reduce direct impact, and solve the impact powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

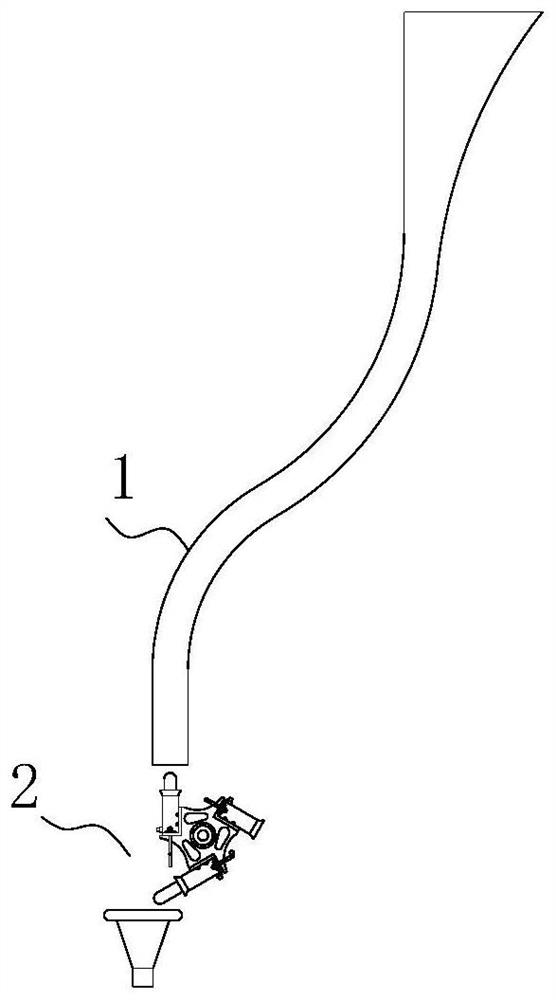

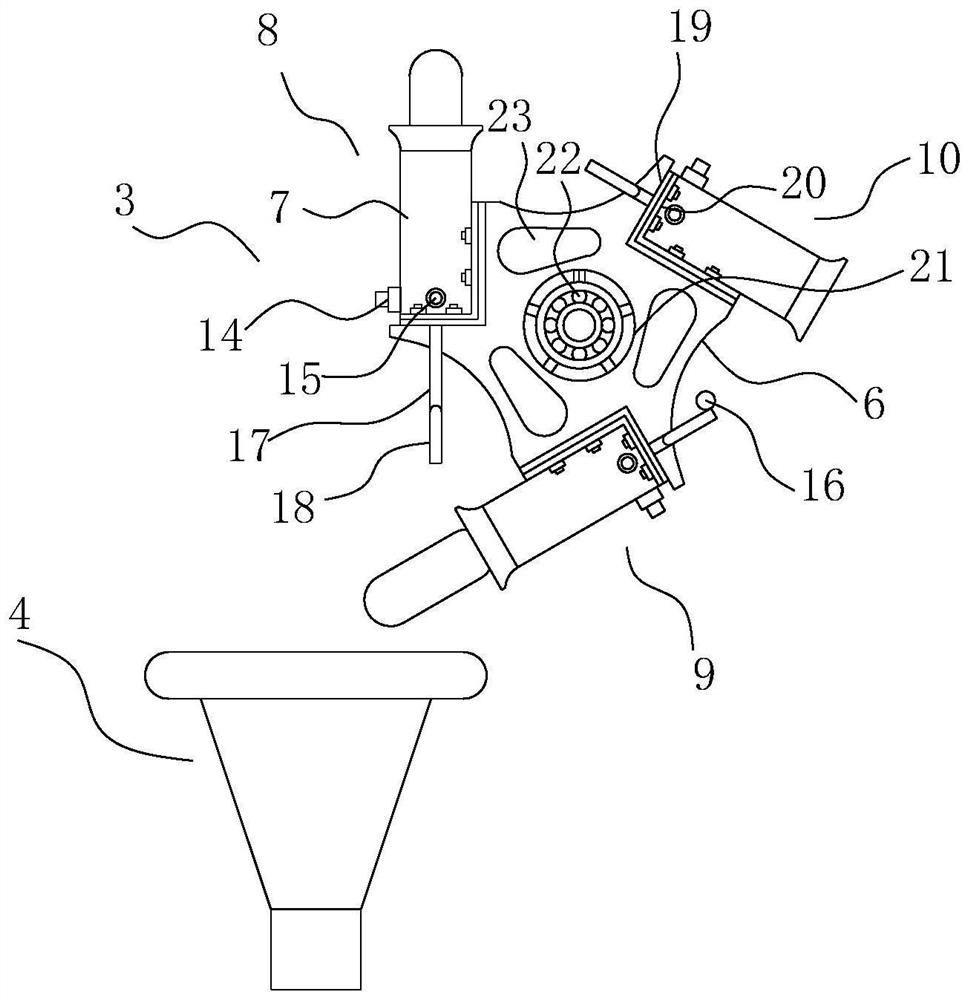

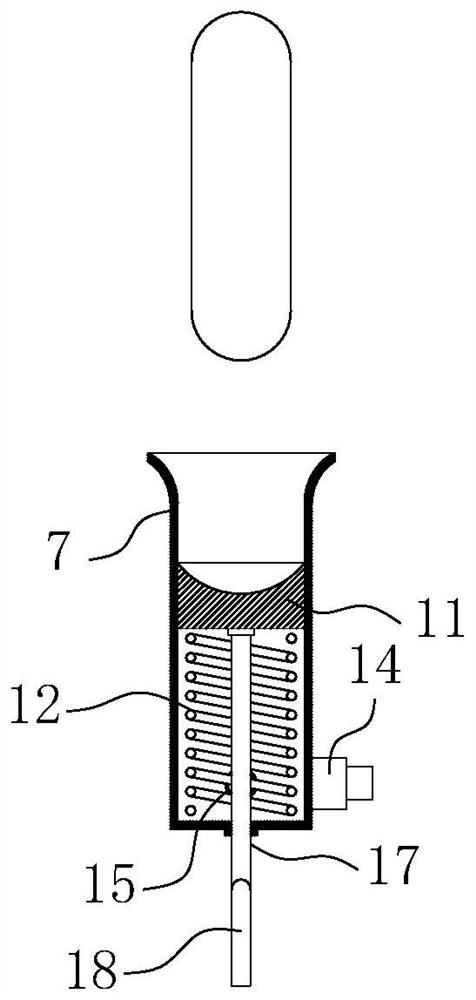

[0022] Such as Figure 1-4 As shown, a feeding system for the production of glass bottles includes a guide groove 1, which is used to guide the gobs sent from the molten pool from a high position to a low position, and the guide groove 1 is usually in a smooth arc shape , to facilitate the smooth drop of gobs. Compared with the traditional feeding system, the present invention has the biggest difference in that, as figure 1 As shown in , the present invention also includes a buffer feeding device 2 arranged at the lower end of the guide groove 1. As the name suggests, the buffer feeding device 2 is used to transfer the material gob that slides along the guide groove 1 to the primary mold, and at the same time, the material gob In order to ensure the effective control of the position and attitude of the drop, such as figure 2 As shown in , the buffer feeding device 2 of the present invention includes a buffer transfer device 3 and a receiving hopper 4 . The receiving hopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com