Cooling system and control method thereof

A cooling system control and cooling system technology, applied in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., can solve the problem that the carrier cannot achieve the preset cooling effect and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

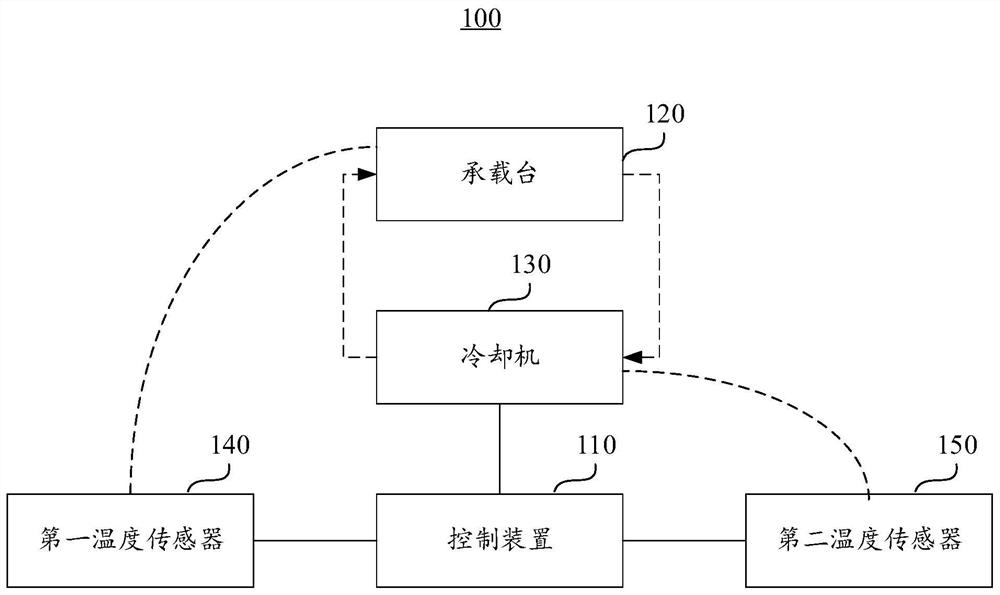

[0042] As mentioned in the background technology, at present, a cooling machine is usually used to cool the chip during the ion implantation process. By connecting the water inlet and outlet of the cooling machine with the carrying platform, the effect of injecting deionized water into the carrying platform is realized. Furthermore, chip cooling is realized by means of heat transfer. However, due to problems such as hardware aging of the loading platform or the cooling machine, the coolant flowing through the channel of the loading platform cannot achieve the expected cooling effect, and thus the loading platform cannot reach the preset temperature.

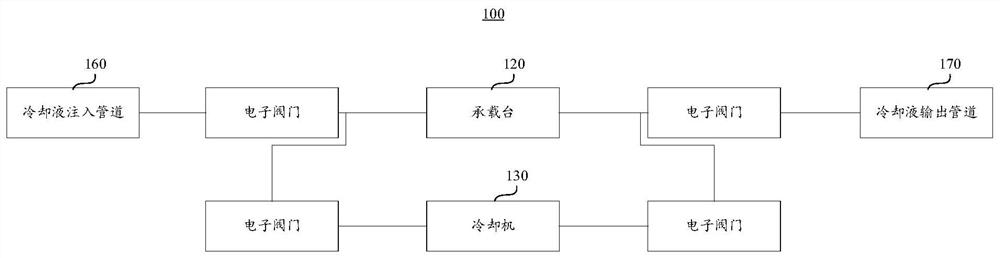

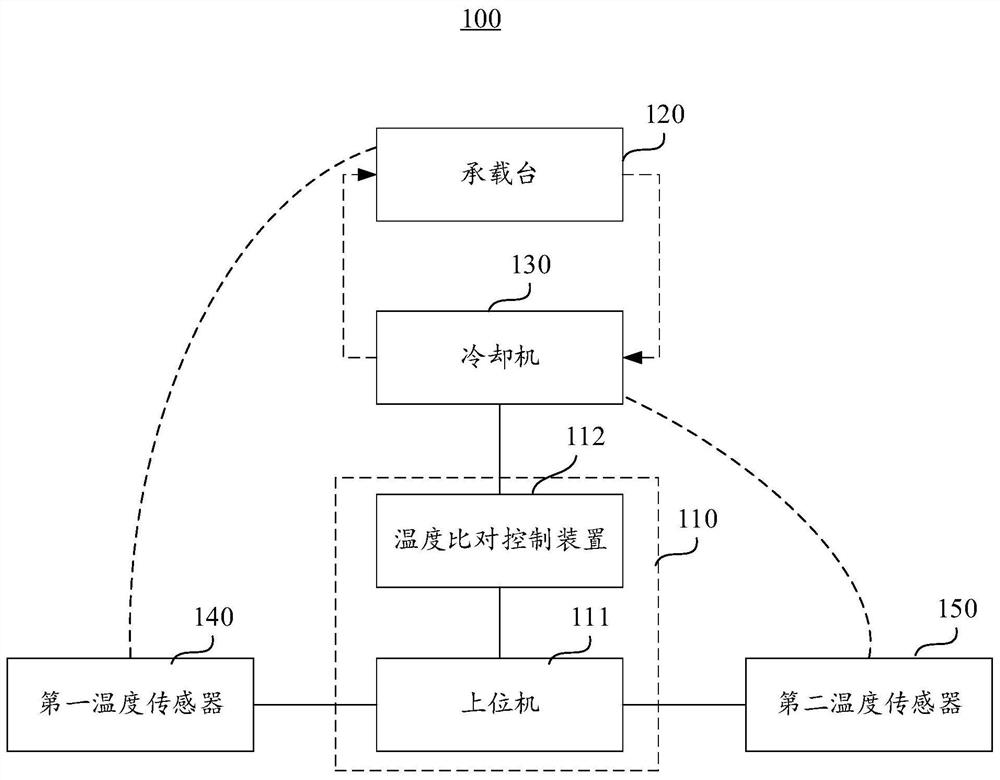

[0043] In view of this, in order to solve the problem that the carrying platform cannot reach the preset temperature, the application provides a cooling system, which obtains the first temperature of the carrying platform and the second temperature of the water inlet of the cooler through the control device, and adjusts the coolin...

no. 2 example

[0070] Based on the first embodiment, the embodiment of the present application also provides a cooling system control method, please refer to Figure 4 , the method includes:

[0071] S102. Obtain the first temperature of the carrying platform and the second temperature of the water inlet of the cooling zone machine, and the carrying platform is used to place chips to be cooled.

[0072] S104. Adjust the amount of water delivered to the loading platform from the water outlet of the cooling machine according to the first temperature and the second temperature.

[0073] Among them, see Figure 5 , S104 includes:

[0074] S1041, determine whether the difference between the first temperature and the second temperature is greater than a first threshold, wherein the first threshold is greater than the second threshold, if yes, perform S1042, and if not, perform S1043.

[0075] S1042, reducing the water volume at the water outlet of the cooling machine, so as to reduce the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com