Processing method of hotpot condiment with stable peppery degree

A technology of hot pot base material and processing method, applied in food science and other directions, can solve the problems of decreased numbness, affecting the sensory quality of hot pot base material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for processing hot pot bottom material with stable numbness, comprising the steps of:

[0025] Step I: Zanthoxylum bungeanum treatment, soak the raw materials of Zanthoxylum bungeanum in cold water at 0°C for 3-5 minutes, drain the water, and set aside;

[0026] Step II: Stir-fry the bottom material of the hot pot in sections, and fry the raw and auxiliary materials. The pepper is cut 3 to 5 minutes before it is out of the pot, and the frying temperature after adding the raw material of the pepper is 100-110°C; this can avoid The numbing substance is lost due to long-term high-temperature frying;

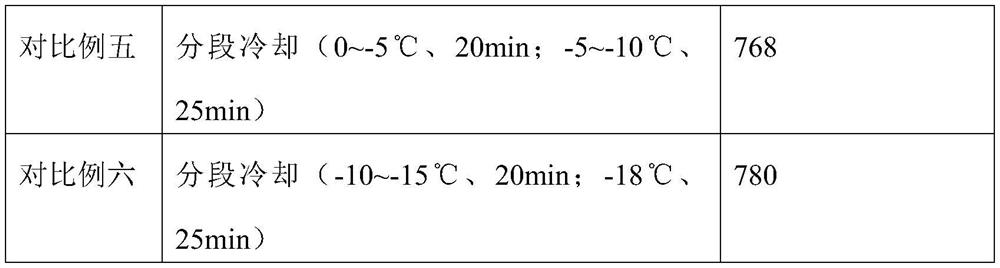

[0027] Step III: Cooling in sections, fill the fried hot pot bottom material while it is hot, and put it in the freezer for rapid cooling in sections to avoid the reduction of the content of numb substances caused by long-term high temperature. The specific operation of stage cooling is as follows: the first stage: cooling at -5~-10°C for 20 minutes; the second stag...

experiment example 1

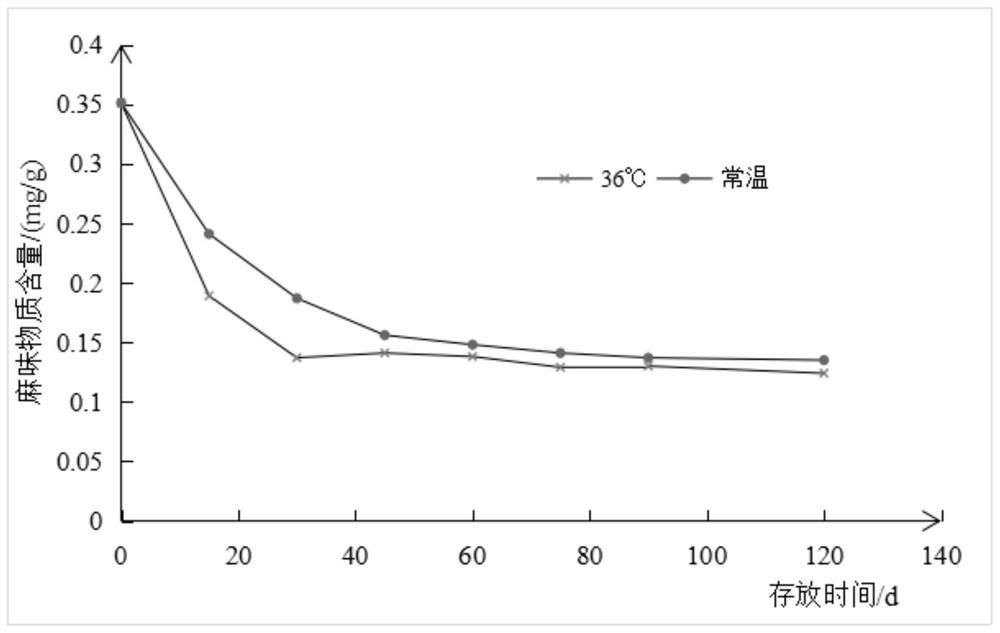

[0041] Experimental Example 1: Effects of Different Treatment Methods on the Content of Mamisin

[0042] The hot pot seasonings prepared in the above-mentioned examples and comparative examples were tested for the content of marmisin, which was detected by the method in GH / T 1291. Three parallel experiments were carried out for each group, and the results were expressed as the average value. From the data in Table 1, it can be seen that without pretreatment of peppercorns, it will be difficult to dissolve the anesthetics in the peppercorns, resulting in a decrease in the content of the anesthetics in the hot pot bottom material; and frying with other ingredients 15 minutes before the pot will result in a numb taste The hemp flavoring is lost due to long-term high-temperature frying; and although the loss of hemp flavoring is less when added 1 minute before the pot, it will cause a bitter taste in the hot pot bottom material and affect the sensory quality. Cooling at room tempe...

experiment example 2

[0046] Experimental Example 2: Effects of Different Stir-Frying Conditions on the Content of Mamisin

[0047] Experimental design: Put 5g of dried Zanthoxylum bungeanum in 250g of oil at different temperatures (100°C, 115°C, 130°C) and fry for different times (10min, 20min, 30min). Afterwards, use a cooking machine to beat well, and take samples to detect the content of hemp flavoring, and the test results are shown in Table 2.

[0048] Table 2 Unit: ug / g

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com