Cotton fines recovery device for spinning

A recovery device and fine chip technology, which is applied in the field of textile cotton fine chip recovery device, can solve the problems of easy sliding device, inability to locate, long-time manual operation, etc., and achieve the effect of flexible opening and closing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

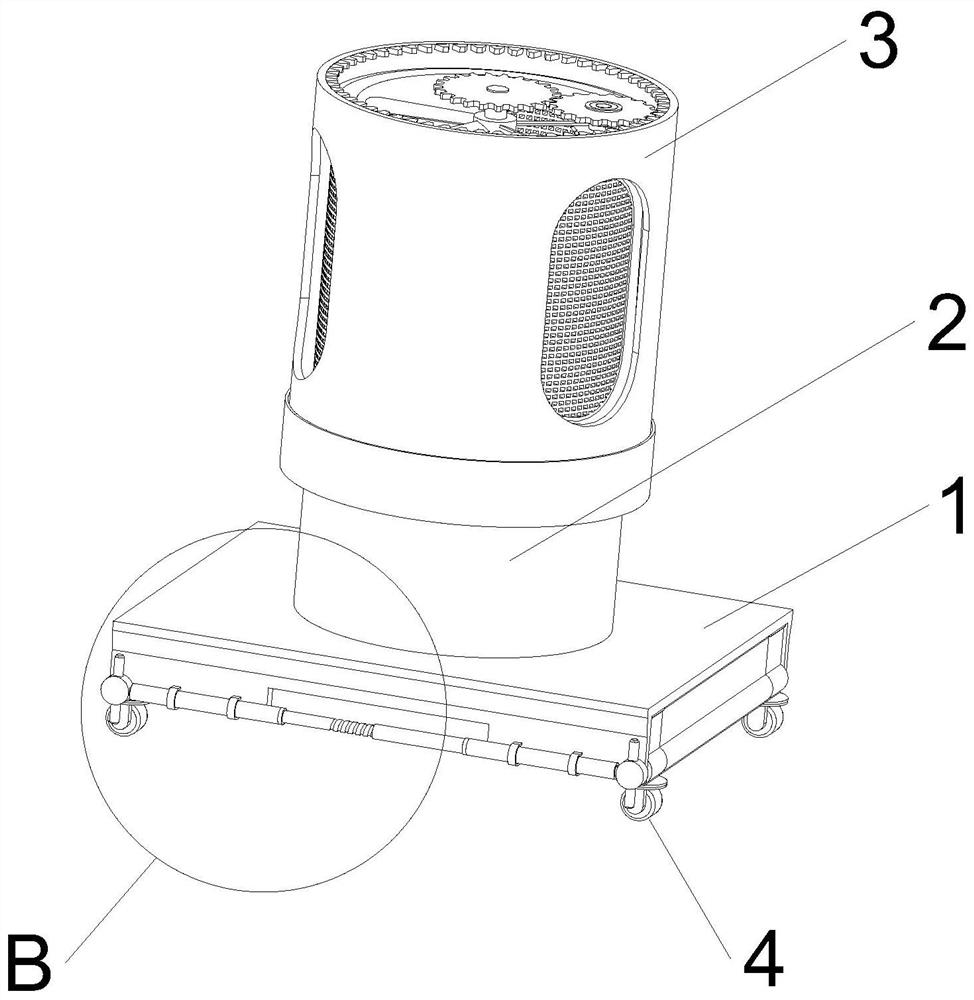

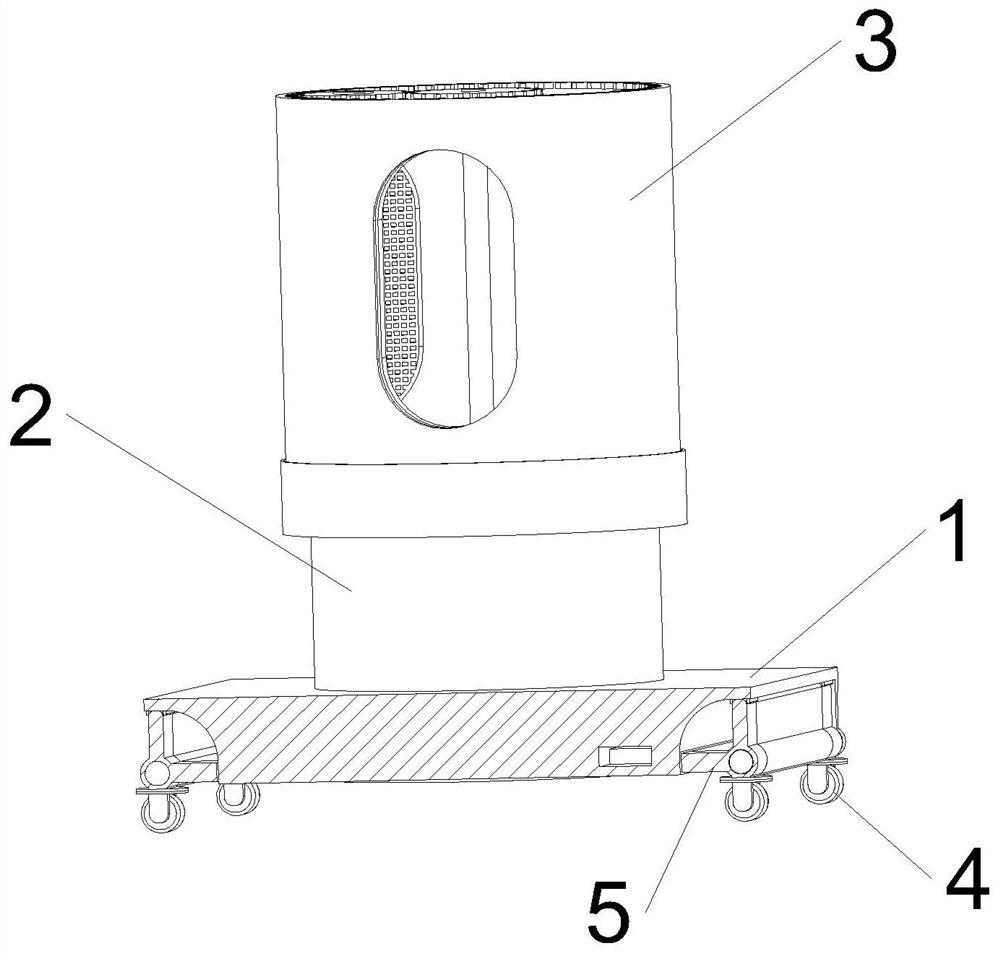

[0047] see Figure 1-Figure 6 As shown, a cotton fines recovery device for weaving includes a base 1, an air cylinder 2 is connected to the upper surface of the base 1, a rotating cover 3 is sleeved on the outer wall of the air cylinder 2, and a turning mechanism 5 is movably connected to the lower surface of the base 1 , the lower surface of the base 1 is movably connected with the universal wheel 4 through the turning mechanism 5;

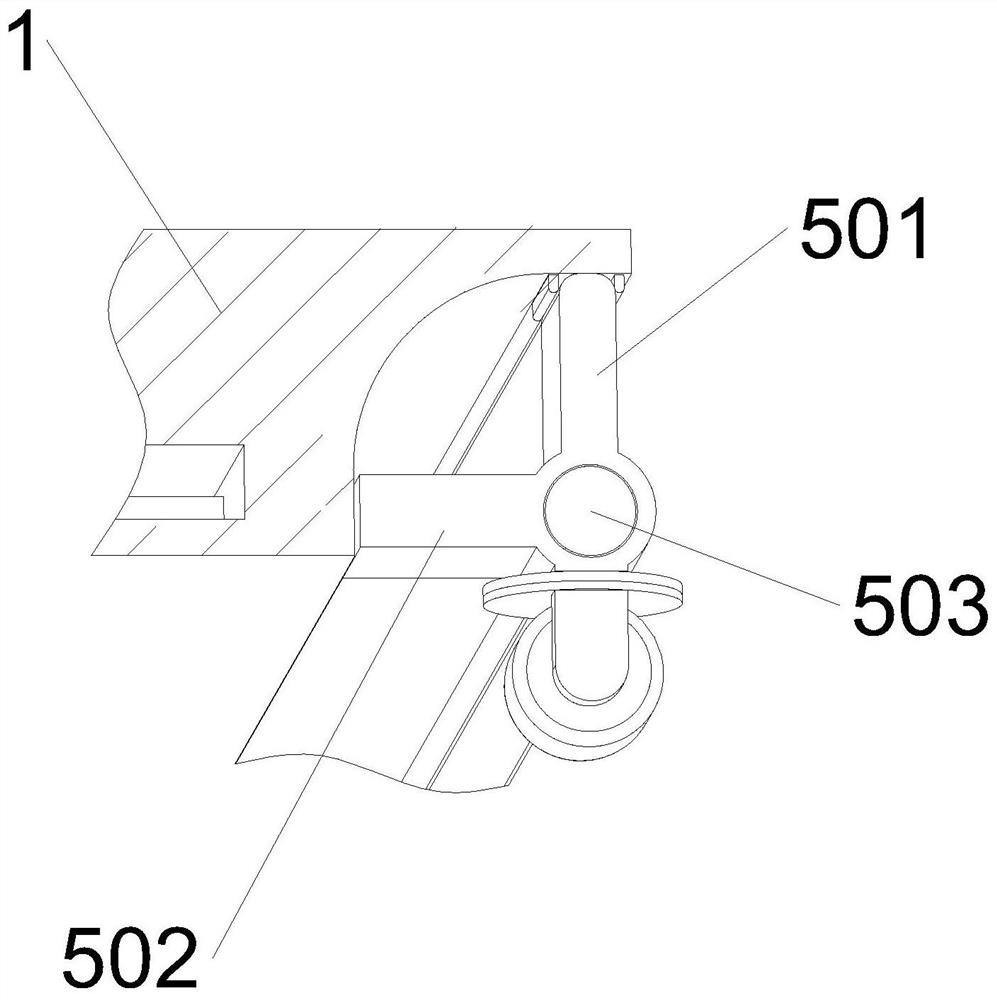

[0048] Turning mechanism 5 includes stabilizing plate 501, support plate 502, rotating shaft 503, mounting seat 504, first fixed pin 505, second fixed pin 506 and the third fixed pin 507, rotating shaft 503 is connected to base 1 two ends in rotation, rotating shaft 503 The outer wall is fixedly connected with a cylindrical tube, and the stabilizing plate 501 and the supporting plate 502 are fixedly connected to the outer wall of the cylindrical tube respectively. The stabilizing plate 501 and the supporting plate 502 are vertically arranged, and...

Embodiment 2

[0050] see Figure 7-Figure 8 As shown, a bottom filter screen 8 is installed inside the hole on the lower surface of the base 1, and the drive shaft 13 passes through the center of the bottom filter screen 8 along the vertical direction. The scraper 9 rotates on the bottom filter 8, the upper surface of the scraper 9 is close to the lower surface of the bottom filter 8, and the cotton fines adsorbed on the bottom filter 8 are gradually pushed to the outside of the bottom filter 8, and the inside of the base 1 There is a collection tank 11, which is finally pushed into the collection tank 11. The collection tank 11 is ring-shaped and sleeved on the outside of the bottom filter 8. One end of the scraper 9 is fixedly connected with a push plate 901. When the scraper 9 rotates, it drives the push plate at one end. 901 rotate together, the push plate 901 is slidably connected inside the collection tank 11, one side of the collection tank 11 is connected with the hopper 12, the cot...

Embodiment 3

[0052] see Figure 8-Figure 13 As shown, the side filter screen 17 is fixedly installed in the hole provided on the side wall of the blower 2, and the internal gear 14 is fixedly installed on the inner wall of the rotating cover 3. The internal gear 14 is located at the top of the rotating cover 3. The internal gear 14, the driving gear 15 and the transmission The gear 16 is located at the same height, and the internal gear 14, the driving gear 15 and the transmission gear 16 have the same thickness. The driving gear 15 is fixedly installed on the top of the driving shaft 13, and the driving shaft 13 rotates, driving the driving gear 15 on the top to rotate, and the top of the air duct 2 moves Connected with transmission gear 16, driving gear 15 is meshed with transmission gear 16 and connected, driving gear 15 drives transmission gear 16 to rotate when rotating, transmission gear 16 is meshed with internal gear 14 and is connected, and transmission gear 16 drives rotating cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com