Inverse Brayton cryogenic box rapid refrigeration system and operation control method thereof

A technology for a refrigeration system and a low temperature box is applied in the field of gas inverse Brayton cycle low temperature box refrigeration, which can solve the problems of the inability of the turbo compressor to perform quickly, the cooling speed of the system is slow, and the quick freezing ability is weak. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

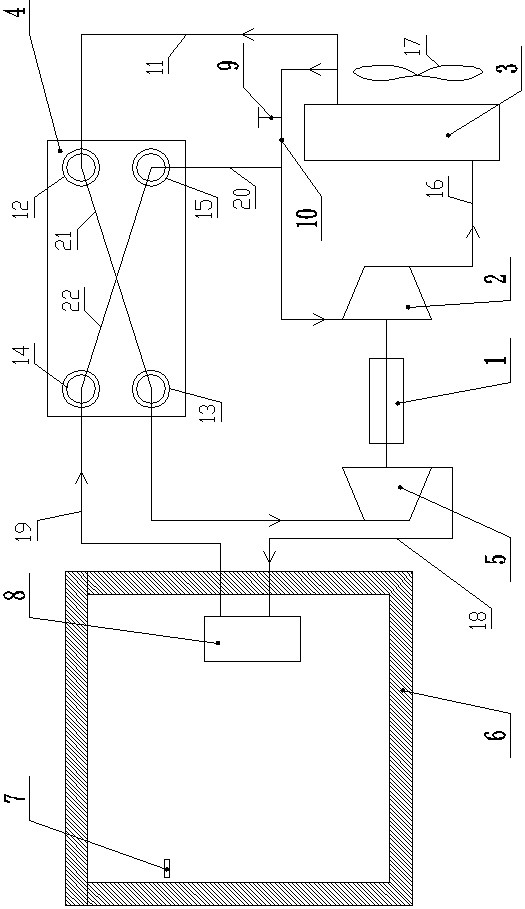

[0033] like figure 1 As shown in the figure, the rapid refrigeration system of the reverse Brayton low temperature box of the present invention includes a cooling device 8, an expander 5, a turbo compressor 2, an aftercooler 3 and a heat recovery device located in the box 6, which are sequentially and circulated through pipelines. The compressor 4 , the turbo compressor 2 and the expander 5 are driven by the high speed motor 1 . It also includes an electronic control device, which is connected to the turbo compressor 2 and the high-speed motor 1; the normal working speed of the high-speed motor 1 is 100,000 revolutions per minute.

[0034] Between the outlet pipeline of the aftercooler 3 (that is, the second high temperature pipeline 11 ) and the inlet of the turbo compressor 2 is provided a bypass pipeline 10 for producing a temporary gas short-circuit phenomenon. The bypass pipeline 10 is provided with a bypass pipeline 10 . The bypass solenoid valve 9 is connected to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com