Ultrasonic vibrator for metal drawing and drawing mechanism

An ultrasonic and vibrator technology, applied in the field of ultrasonic vibrator and drawing mechanism, can solve the problems of severe deformation, large deformation force and friction force, surface defects, etc., and achieve the goal of reducing drawing force, improving surface quality and improving fatigue resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

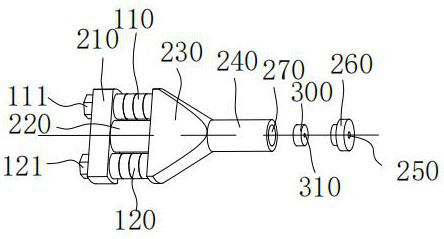

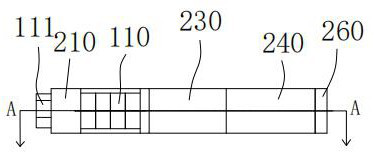

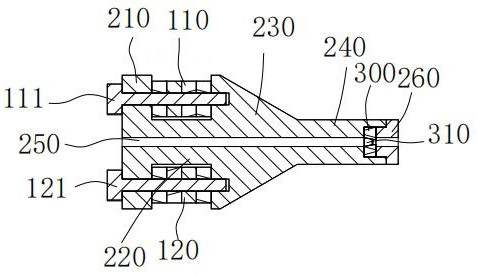

[0032] An ultrasonic vibrator, such as Figure 1 to Figure 3 shown, including: transducer and horn.

[0033] A through hole 250 is provided inside the horn, and the horn includes a base 210, a first rod body 220, a first connecting body 230 and a second rod body 240 connected sequentially from left to right; the base 210 and the first connecting body 230 A transducer is disposed between them; the transducer includes at least two piezoelectric stacks, and the vibration direction of the piezoelectric stacks is parallel to the extending direction of the through hole 250 . Preferably, the base 210 of the horn, the first rod body 220 , the first connecting body 230 and the second rod body 240 are integrally structured.

[0034] The above-mentioned ultrasonic vibrator can be set on the drawing machine as a part of the drawing machine. Preferably, the drawing die 300 can be fixed in the above-mentioned ultrasonic vibrator. The material to be drawn passes through the horn through t...

Embodiment 2

[0041] The content of this embodiment is the same as that of Embodiment 1 and will not be repeated. The difference is that: Figure 4 to Figure 6 As shown, in this embodiment, the number of piezoelectric stacks is four, which are respectively the first piezoelectric stack 110, the second piezoelectric stack 120, the third piezoelectric stack 130 and the fourth piezoelectric stack 140. A piezoelectric stack 110 , a second piezoelectric stack 120 , a third piezoelectric stack 130 and a fourth piezoelectric stack 140 are sequentially arranged around the first rod 220 at intervals of 90°. The increase in the number of piezoelectric stacks makes the vibration of the ultrasonic vibrator play a superimposed strengthening effect. It should be known that the number of piezoelectric stacks can also be set to three or five or more, and its working principle is the same as that of the present invention, and the scope of protection of the present invention includes but is not limited to th...

Embodiment 3

[0045] A pulling mechanism such as Figure 7 with Figure 8 As shown, it includes the ultrasonic vibrator, the fixing seat 400 and the mandrel 500 as described in the first embodiment; The drawing mechanism in this embodiment is used for drawing the pipe, the pipe to be drawn is inserted into the through hole 250, the mandrel 500 is placed in the core of the pipe to be drawn, and the drawing pliers pull the pipe to be drawn toward the end of the gland 260. Moving to the right, the pipe to be drawn passes through the drawing hole 310, and under the extrusion of the drawing die 300, the outer diameter of the pipe to be drawn is reduced. During the whole drawing process, the ultrasonic vibrator drives the drawing die 300 to vibrate at the same frequency. According to different drawing procedures, the state of linear vibration and torsional vibration can be selected.

[0046] Further, an ultrasonic vibrator is arranged on the fixing seat 400 . The ultrasonic vibrator here drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com