Saw cutting center based on multiple angles of 45-90 degrees

A multi-angle, sawing technology, which is applied in the direction of metal sawing equipment, sawing machine, metal processing equipment, etc., can solve the problems of low sawing efficiency, labor loss, waste of time, etc., achieve low production cost and speed up sawing , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

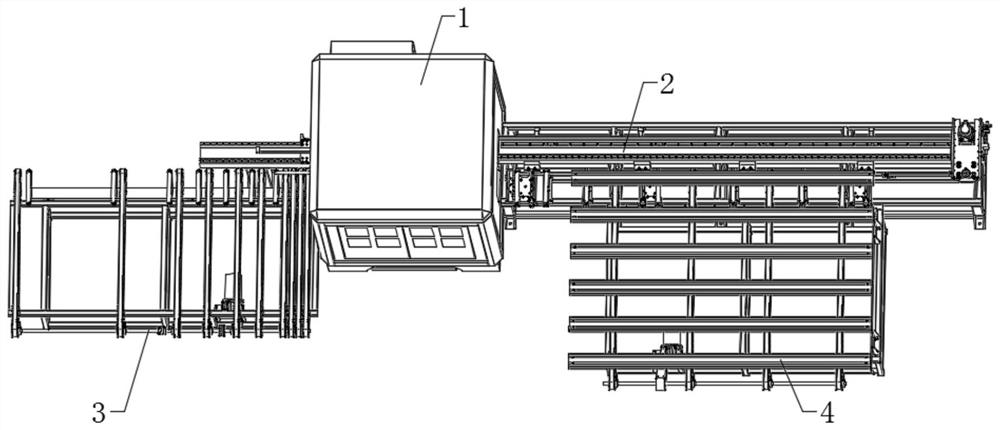

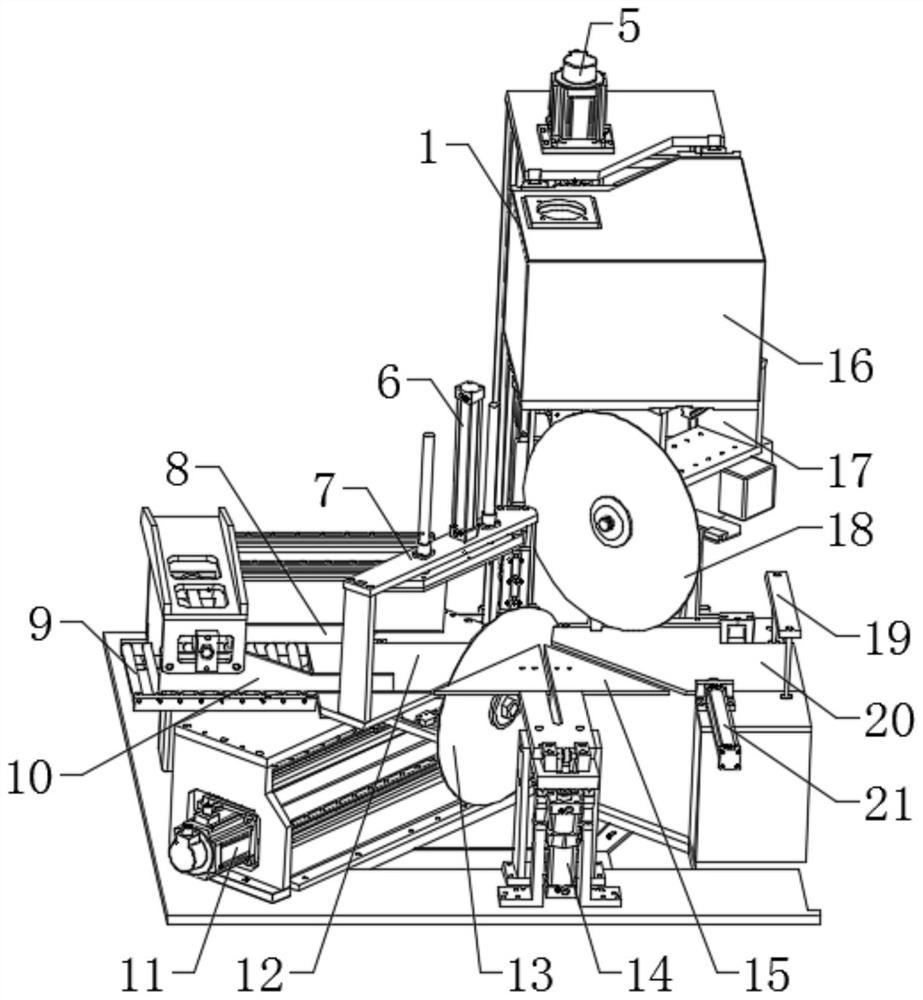

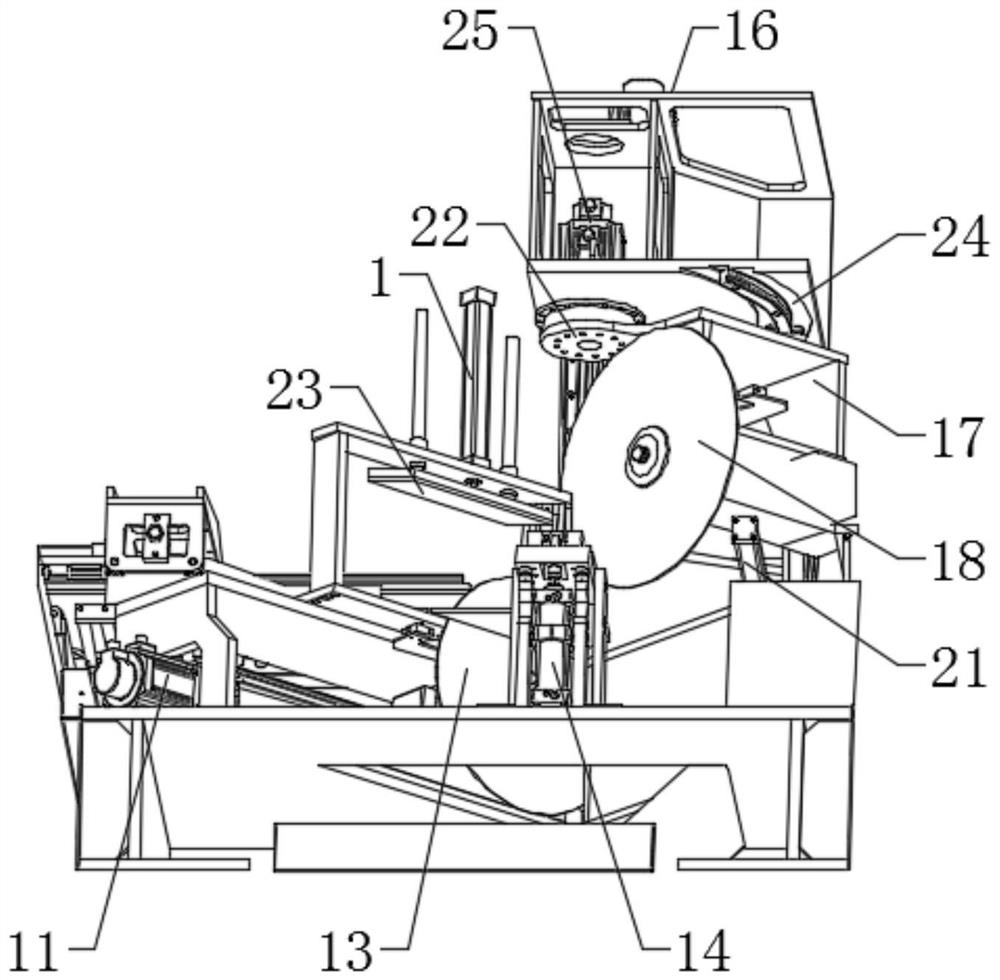

[0031] see Figures 1 to 5 , the present invention provides a technical solution: a multi-angle sawing center based on 45° to 90°, including a profile sawing center 1, the two sides of the profile sawing center 1 are respectively provided with a feed center 4 for feeding and a In the discharge center 3 of the discharge, the feed center 4 is provided with a feed center 2 for transporting profiles into the profile sawing center 1. The profile sawing center 1 includes a sawing table 16, and the sawing table 16 is equipped with a The reversing motor 25 of reversing conversion, the reversing motor 25 output end is provided with the reversing rotating plate 22 that cooperates with sawing platform 16 rotations, and reversing rotating plate 22 one sides is fixed with reversing bracket 17, and reversing bracket 17 is set There is a direction-changing track 24 that slides with the direction-changing bracket 1 and is fixed at the bottom of the sawing table 16. The direction-changing brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com