Transfer box for electronic special materials

A transfer box, electronic technology, applied in the direction of transportation and packaging, rigid containers, containers to prevent mechanical damage, etc., to achieve the effect of reducing space occupation, convenient storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

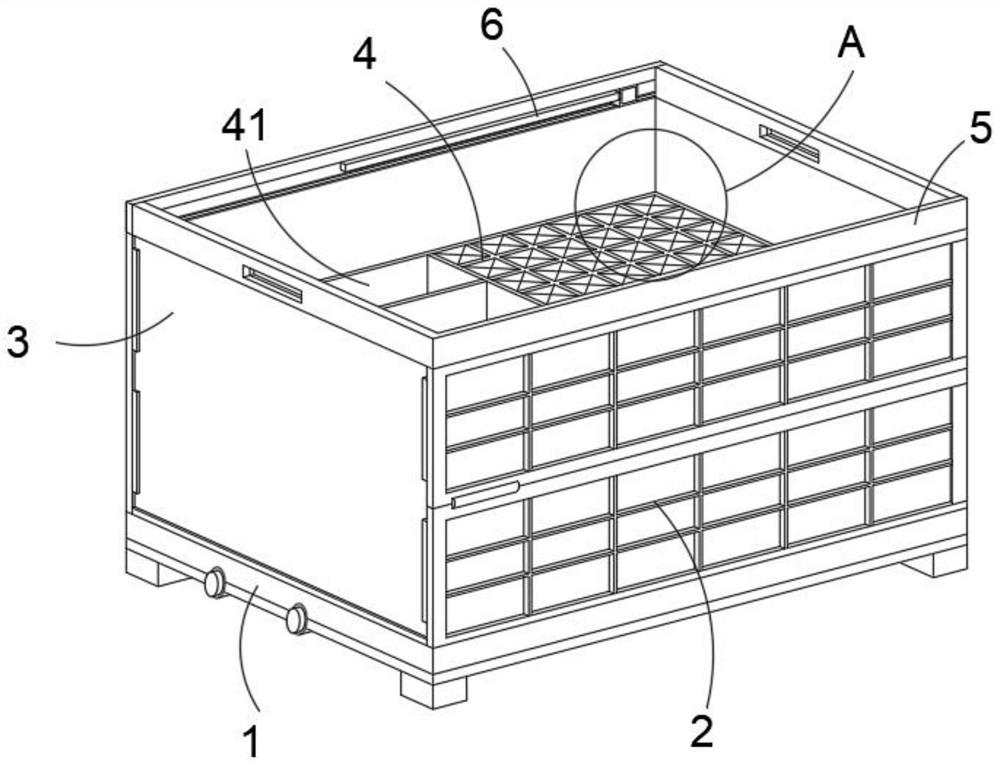

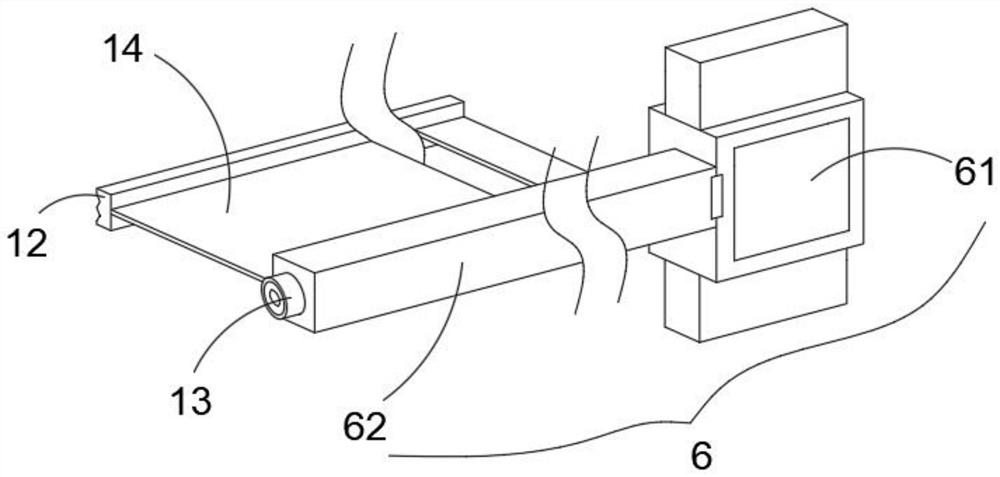

[0037] This embodiment provides the specific structure of the cover assembly, such as Figure 1-3 As shown, an air pump assembly is installed on the side of the base 1, and the air pump assembly is used to inflate and deflate the bag main body 4;

[0038] Both sides of the inner wall of the top frame 5 are provided with a cover assembly 6, and the cover assembly 6 includes a sliding piece 61 and a folding rod 62 connected to one side of the sliding piece 61 through a rotating shaft, and the folding rod 62 is turned inwardly and equipped with a torsion spring The rotating shaft part 13, the surface of this rotating rod is wound with the winding film 14 that is used to cover the opening above the top frame 5;

[0039] When the above-mentioned cover assembly 6 is specifically used:

[0040] Flip the folding rod 62 by 90° so that two groups of folding rods 62 are distributed parallel to each other, slide the slider 61 close to the position of the side flap 3, then hold the magnet...

Embodiment 2

[0050] This embodiment provides the specific structure of the front flap and the side flap, as figure 1 As shown, the front flap 2 includes two groups of flaps, and the adjacent flaps, between the flaps and the top frame 5, and between the flaps and the base 1 are all connected by rotating shafts. A retaining strip for blocking the side flap 3 is provided.

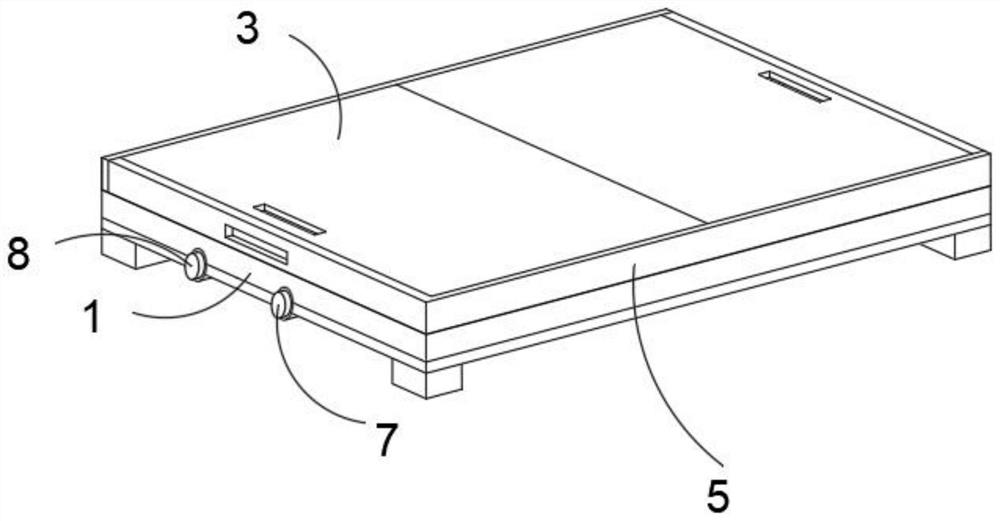

[0051] refer to image 3 As shown, the turning angle of the side flap 3 is 0-90°, and the area where the side flap 3 turns over is located in the inner cavity of the transfer box, and the unfolded front flap 2 is always vertically distributed with the side flap 3 .

[0052] Specifically, when packing the entire transfer box:

[0053] Shrink the bag main body 4 so that there is room for the side flap 3 to turn inwards,

[0054]Then, the side turning plate 3 is turned inward, and the entire top frame 5 is pressed down.

[0055] By adopting the above technical solutions:

[0056] The present invention adopts a folding tr...

Embodiment 3

[0058] This embodiment provides the specific structure of the bag body. The bag body 4 is arranged on the upper surface of the base 1, and one side of the bag body 4 is provided with a side bag body 41. the partitioning capsule 15 of the region;

[0059] refer to Figure 4 As shown, the upper part of the bag main body 4 is provided with several bag openings with a rectangular section, and the opening end of each bag opening is provided with a cover sheet group 11 for closing the bag opening;

[0060] Each of the above pockets can be filled with special electronic materials;

[0061] The above-mentioned cover page set 11 adopts four pieces of triangular-shaped films, and forms a rectangular structure, which is used to close the opening ends of each pocket opening. After putting the electronic special materials to be loaded into the corresponding pocket openings, each film returns to its original state. , so as to realize the function of closed processing.

[0062] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com