Anti-electric-shock wall planing machine

A wall planing machine, anti-electric shock technology, applied in machine tools, grinders, metal processing equipment and other directions suitable for grinding workpiece planes, can solve the problems of difficult operation, heavy dust, low work efficiency, etc., to enhance the heat dissipation effect, reduce Dust pollution and small space occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below with reference to the accompanying drawings.

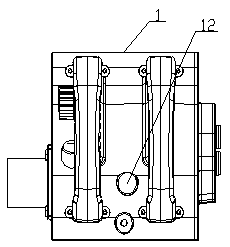

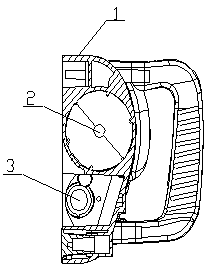

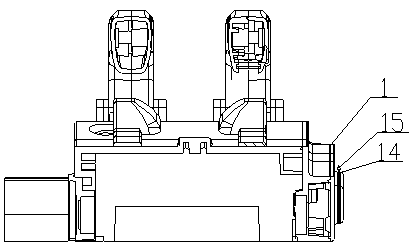

[0015] like Figure 1 to Figure 4 The shown anti-shock wall planer includes a casing 1, a blade group 2 installed at the bottom of the casing 1, and a power device 3 installed inside the casing 1 for driving the blade group 2 to rotate; There are a chamber A and a chamber B, the power unit 3 and the blade set 2 are respectively installed in the chamber A and the chamber B, the chamber A is located on the side of the casing 1 and extends to the outside, and the most The outer side is provided with a ventilation grille, the top edge of the chamber A is also provided with a strip-shaped socket 14, the length of the strip-shaped socket 14 is greater than the length of the ventilation grille, and a dust-proof device 15 embedded in the strip-shaped socket 14 is also provided. , the dust-proof device 15 includes an installation handle and a dust-proof net installed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com