Oil-containing self-lubricating material and application thereof

A self-lubricating material and lubricating oil technology, which is applied in applications, inks, household appliances, etc., can solve problems such as shortened service life of lubricating parts, cumbersome preparation process of porous materials, and reduced integrity of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a method for preparing the oil-containing self-lubricating material described in the above technical solution, preferably comprising: sequentially mixing and defoaming the base material, lipophilic filler, and lubricating oil to obtain the oil-containing self-lubricating material.

[0039] In the present invention, the base material, lipophilic filler and lubricating oil are preferably mixed to obtain a prefabricated oil-containing self-lubricating material.

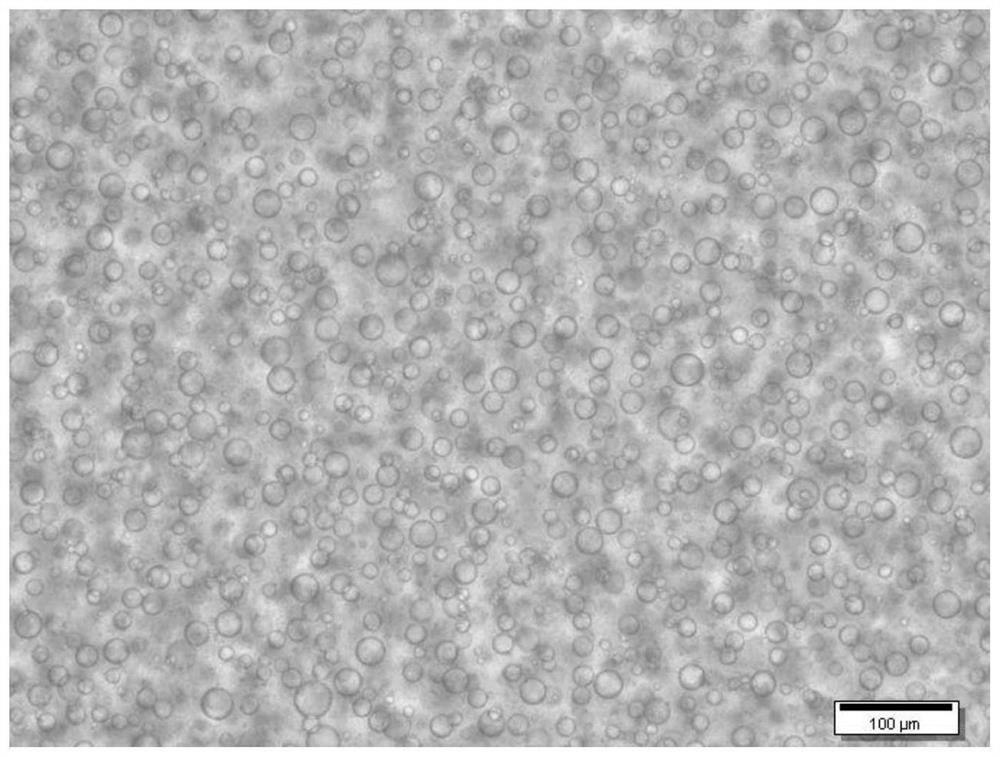

[0040] In the present invention, the order of mixing is preferably that the lipophilic filler is firstly added to the base material, and then the lubricating oil is added. In the present invention, by controlling the mixing order, the lipophilic filler can be coated on the surface of micro-oil droplets, which is more conducive to improving the stability of the oil-containing self-lubricating material.

[0041]In the present invention, the mixing operation preferably includes one...

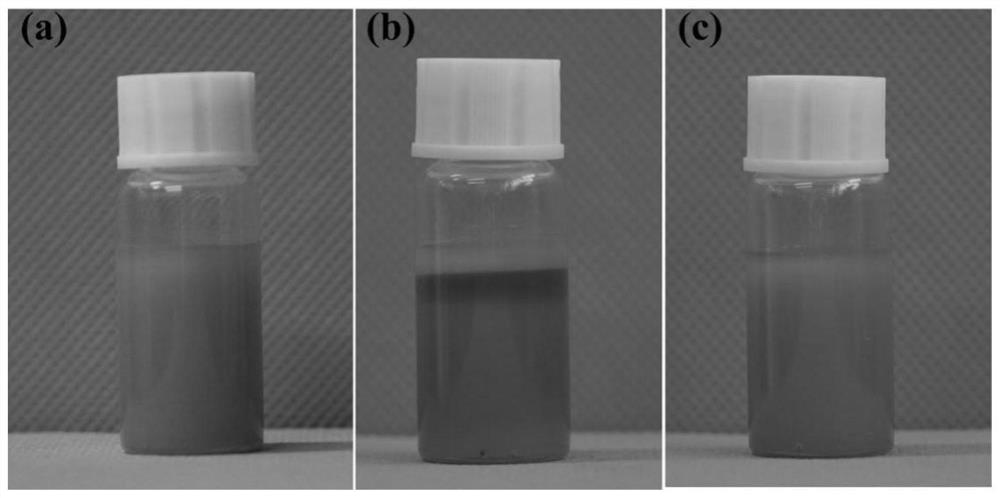

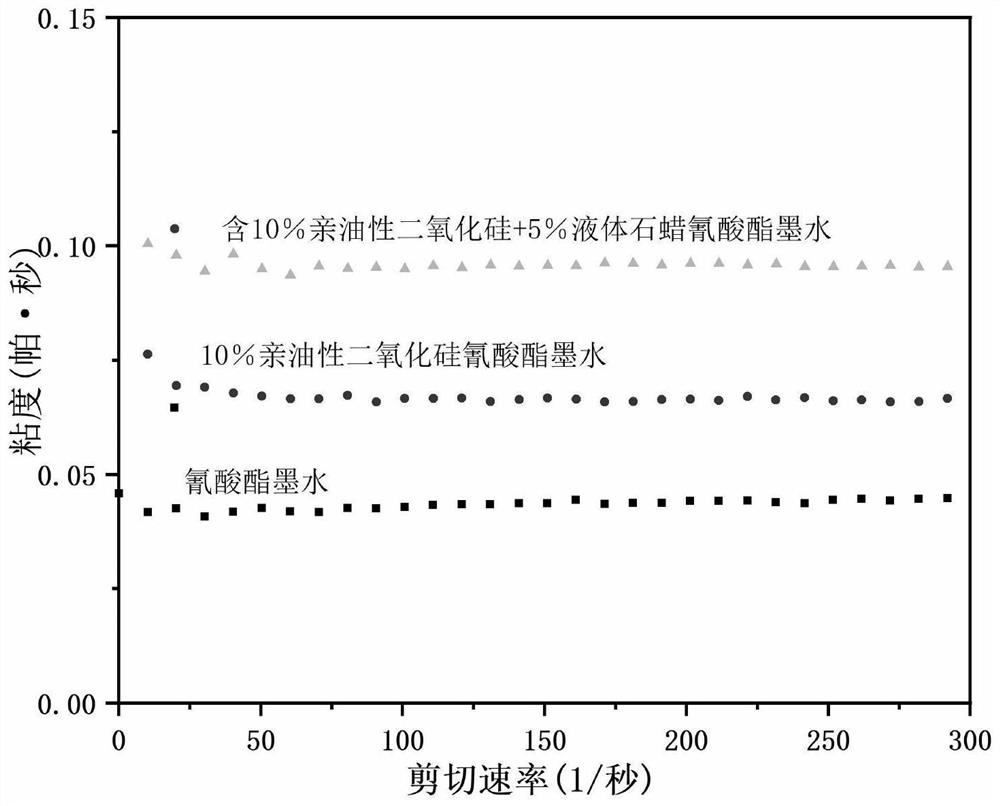

Embodiment 1

[0060] The oil-containing self-lubricating material in this embodiment is composed of base material, lipophilic filler and lubricating oil; the mass ratio of base material, lipophilic filler and lubricating oil is 100:10:5;

[0061] Among them, the matrix material is 3D printing cyanate ester liquid photosensitive ink with a viscosity of 45mPa.s, specifically 100g; the lipophilic filler is silicon dioxide with a particle size of 50nm, specifically 10g; the lubricating oil is liquid paraffin, specifically 5g .

[0062] The preparation method of the above-mentioned oil-containing self-lubricating material is as follows: the base material is first mixed with lipophilic fillers, and then lubricating oil is added for mixing, and then dispersed and defoamed to obtain the oil-containing self-lubricating material;

[0063] Among them, the mixing operation is ball milling, the ball milling speed is 3000 rpm, and the ball milling time is 9 minutes; the mixing temperature is 30° C.; the ...

Embodiment 2

[0067] The mass ratio of the base material, lipophilic filler (silicon dioxide), and lubricating oil in Example 1 is replaced by 100:5:5, and the rest of the technical features are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com