Colorful graphical color-changing fabric based on electronic ink and preparation method

An electronic ink, color graphics technology, applied in chemical instruments and methods, fabrics, woven fabrics, etc., can solve the problems of inability to integrate, the fabric does not have flexibility, etc., achieve high color stability, rich secondary development potential, etc. The effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

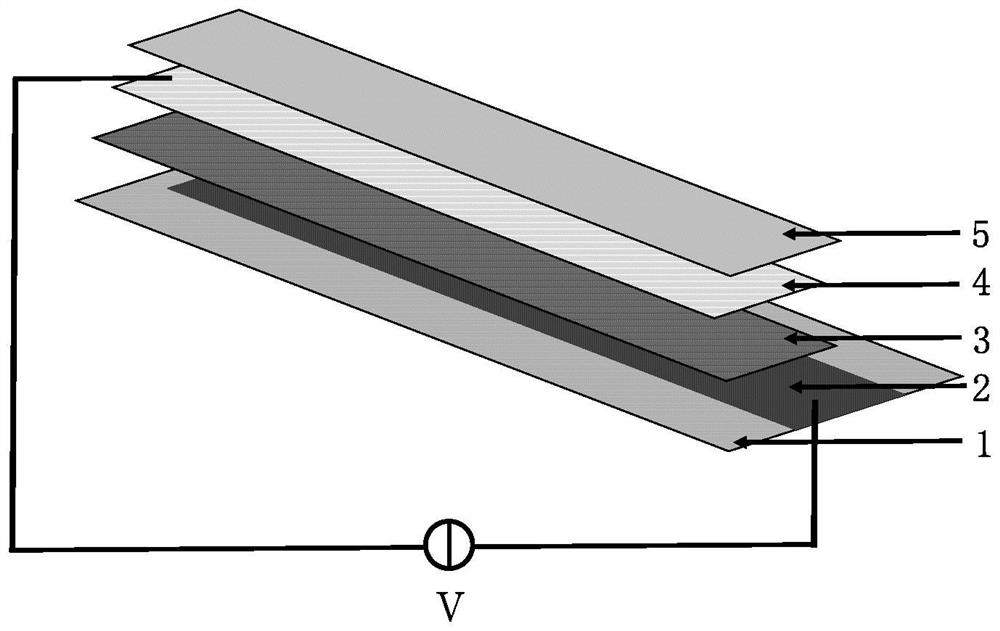

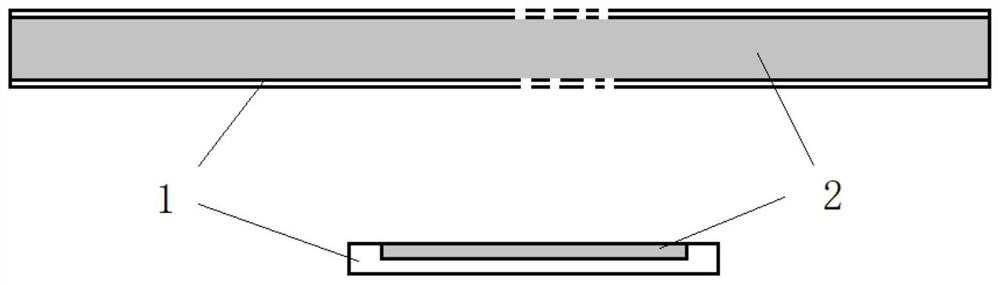

[0036] (1) The conductive yarn and insulating yarn are woven into a double-layer conductive fabric microstrip with a width of 12mm by double-layer warp knitting process. The edge is composed of insulating yarn, and the center surface is composed of conductive yarn. Silver conductive yarn, insulating yarn is 70D24F nylon yarn, and the conductive yarn is woven into the central area of the microstrip. The width of the conductive area is about 10mm, the width of the side layers on both sides is about 1mm, and the square resistance of the conductive microstrip is ~1Ω.

[0037] (2) Coil the woven continuous strip and import it into the rubber scraping machine. A number of microstrips are arranged in parallel, and each is equipped with a dispensing head, and the electronic ink microcapsule slurry and water-based polyurethane mixed slurry are dripped on the microstrips. In the center of the conductive area, the electronic ink is an electrophoretic microcapsule slurry with a density o...

Embodiment 2

[0042] (1) The conductive yarn and insulating yarn are woven into a double-layer conductive fabric microstrip with a width of 12mm by double-layer warp knitting process. The edge is composed of insulating yarn, and the center surface is composed of conductive yarn. Silver conductive yarn, polyester yarn 75D72F is used as the insulating yarn, and the conductive yarn is woven into the central area of the microstrip. The width of the conductive area is about 10mm, and the width of the side layers on both sides is about 1mm. After the microstrip is woven, the conductive area is plated with silver, and the thickness is about 2μm , The square resistance of the conductive microstrip is ~1Ω.

[0043] (2) Coil the woven continuous strip and import it into the rubber scraping machine. A number of microstrips are arranged in parallel, and each is equipped with a dispensing head, and the electronic ink microcapsule slurry and water-based polyurethane mixed slurry are dripped on the micro...

Embodiment 3

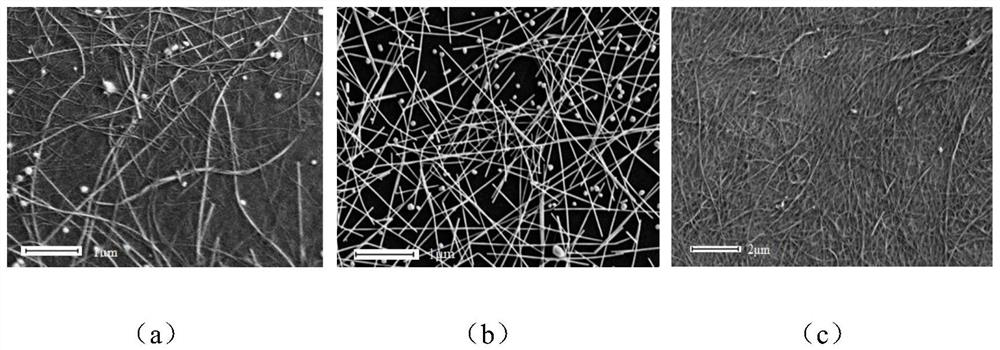

[0048] (1) The conductive yarn and the insulating yarn are woven into a double-layer conductive fabric microstrip with a width of 12 mm by double-layer warp knitting technology. The edge is composed of insulating yarn, and the center surface is composed of conductive yarn. Material-coated conductive yarn, the nanomaterials in the conductive yarn coating are carbon nanotubes and silver nanowires, the specification is 75D3F, the insulating yarn is polypropylene yarn, the specification is 75D36F, and the conductive yarn is woven into the microstrip by high-density knitting technology In the central area, the width of the conductive area is about 10 mm, the width of the side layers on both sides is about 1 mm, and the square resistance of the conductive microstrip is ~1Ω.

[0049] (2) After the woven continuous strip is coiled, it is introduced into the rubber scraping machine, and several microstrips are arranged in parallel, and each is provided with a dispensing head, and the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap