Power-assisted pipeline valve

A pipeline valve and power-assisted technology, which is applied to valve details, safety valves, balance valves, etc., can solve problems that affect the service life of valves, easily cause water hammer effects, and damage valves and pipelines, so as to reduce operating labor and water hammer. Good prevention and control effect, avoiding the effect of line loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the technical content of the present invention, specific embodiments are provided below, and the present invention is further described in conjunction with the accompanying drawings.

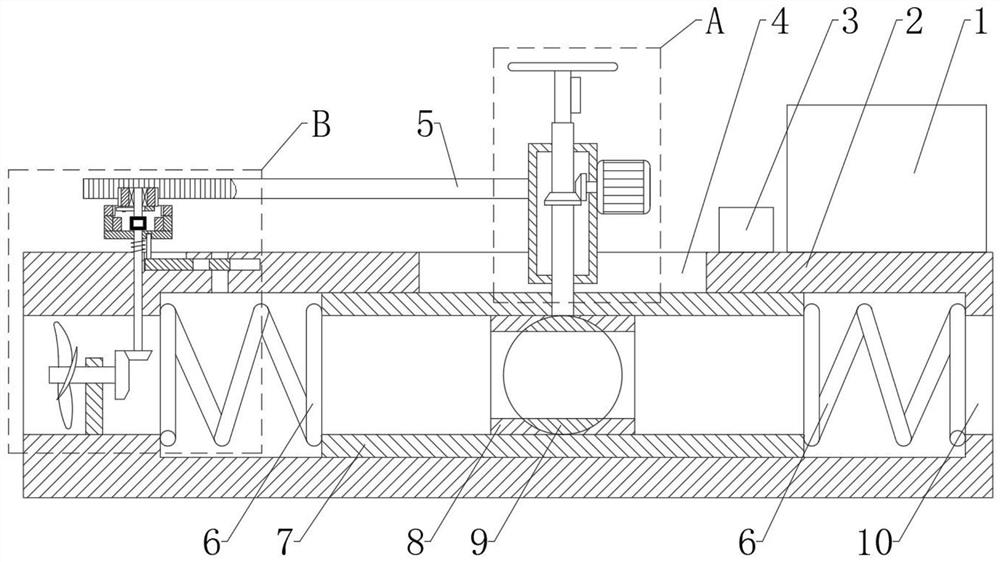

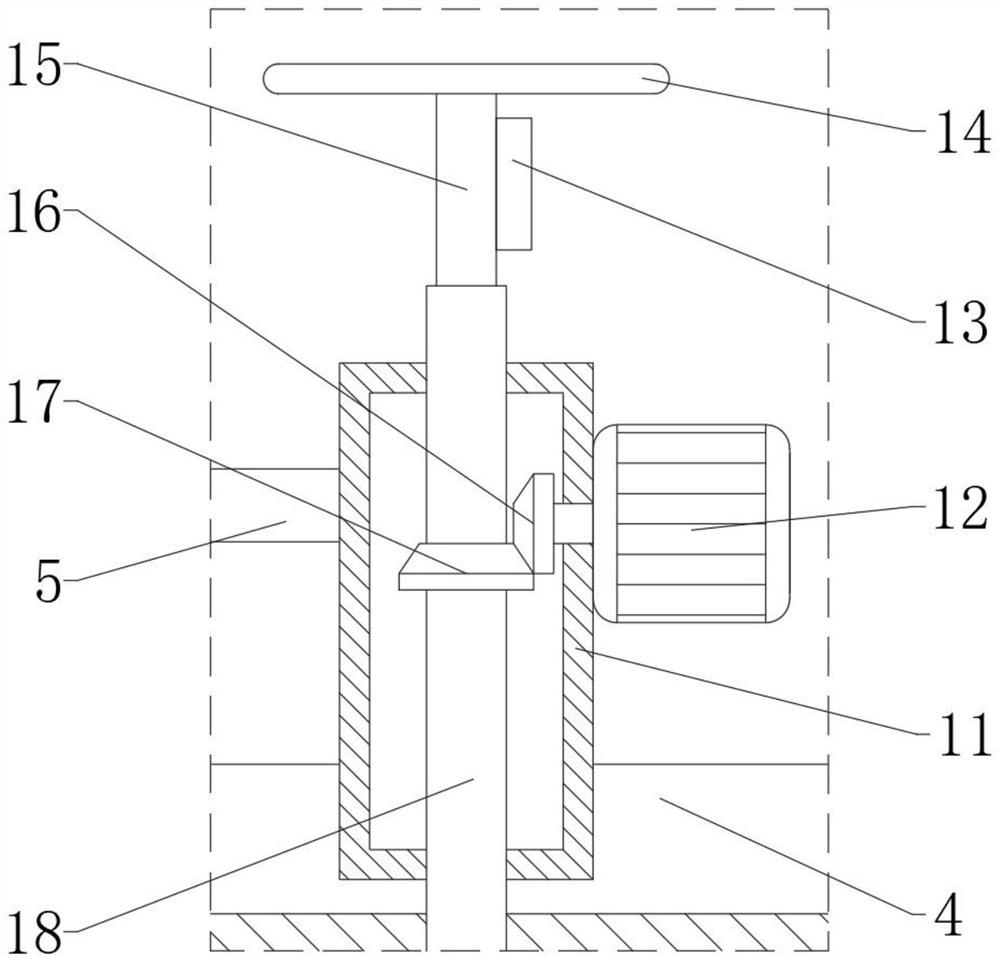

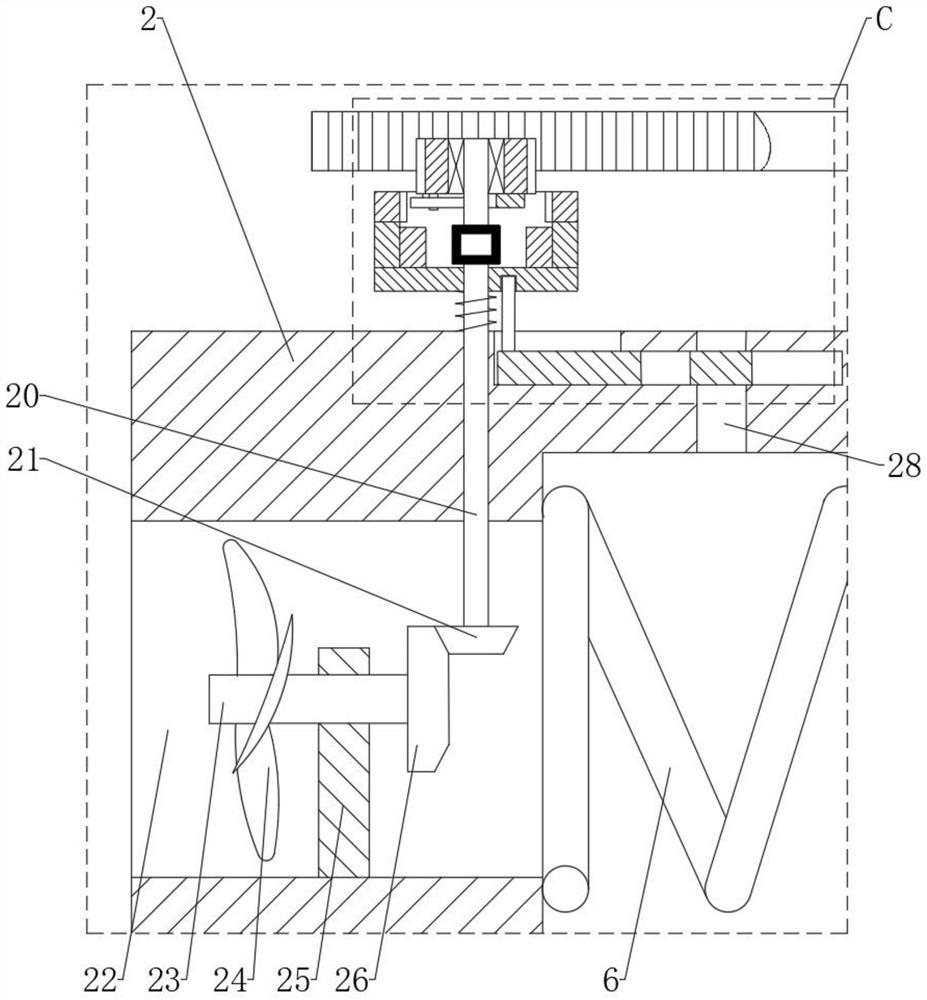

[0028] see Figures 1 to 9 , the present invention provides a power-assisted pipeline valve, which includes a valve body 2 and a pressure relief assembly. The left and right sides of the valve body 2 are respectively provided with a water inlet 22 and a water outlet 10, and the valve is connected to the pipeline through the water inlet 22 and the water outlet 10. , the top of the valve body 2 is provided with a first chute 4, the valve body 2 is slidingly provided with a sliding sleeve 7, both sides of the sliding sleeve 7 are connected with the inner wall of the valve body 2 through the first spring 6, and a ball valve is arranged inside the sliding sleeve 7 Assemblies, the ball valve assembly is used to conduct and block the water flow, the valve stem 18 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com