Control method of flyback power supply and control circuit of flyback power supply

A control method and flyback technology, applied in control/regulation systems, high-efficiency power electronic conversion, electrical components, etc., can solve the problems of bad electromagnetic interference, increase the effective value of primary current, and high operating frequency, and achieve increased transmission. Effects of Power Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

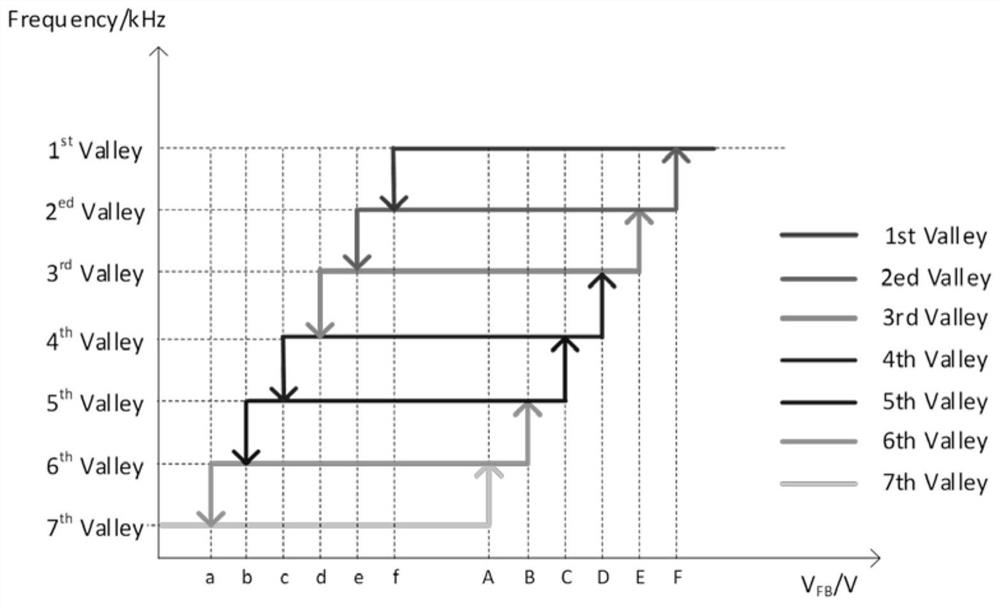

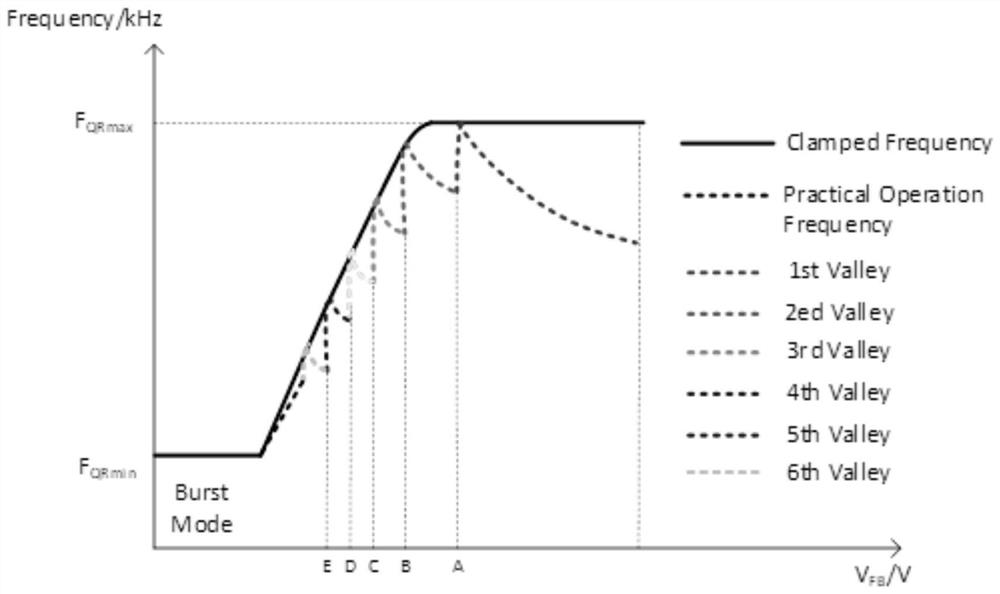

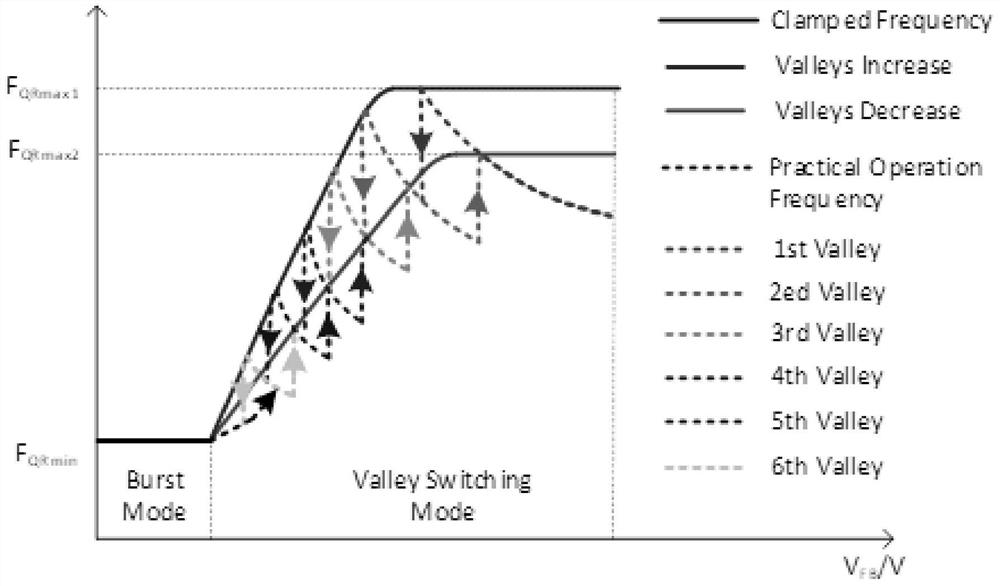

[0040] The operating frequency of the conventional frequency clamping method is as figure 2 As shown, when the QR flyback converter works at the valley switching point, such as point A-E in the figure, frequent valley switching will occur; the reason is: when the converter works near point A, as the load increases slowly, the conversion The converter transitions from the second valley working state to the first valley working state. When working in the first valley working state on the right side of point A, the converter’s transmission power increases due to the increase in operating frequency, and the VFB voltage is adjusted through a negative feedback loop. Decrease, so that the converter returns to the second valley working state on the left side of point A. In this way, the converter will repeatedly switch between the first valley and the second valley.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com