Water sampling immersion probe

An immersion, water sampling technology, applied in sampling, testing water, sampling devices, etc., can solve problems such as removal, clogging of membrane filters, etc., to achieve the effect of strong mechanical cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

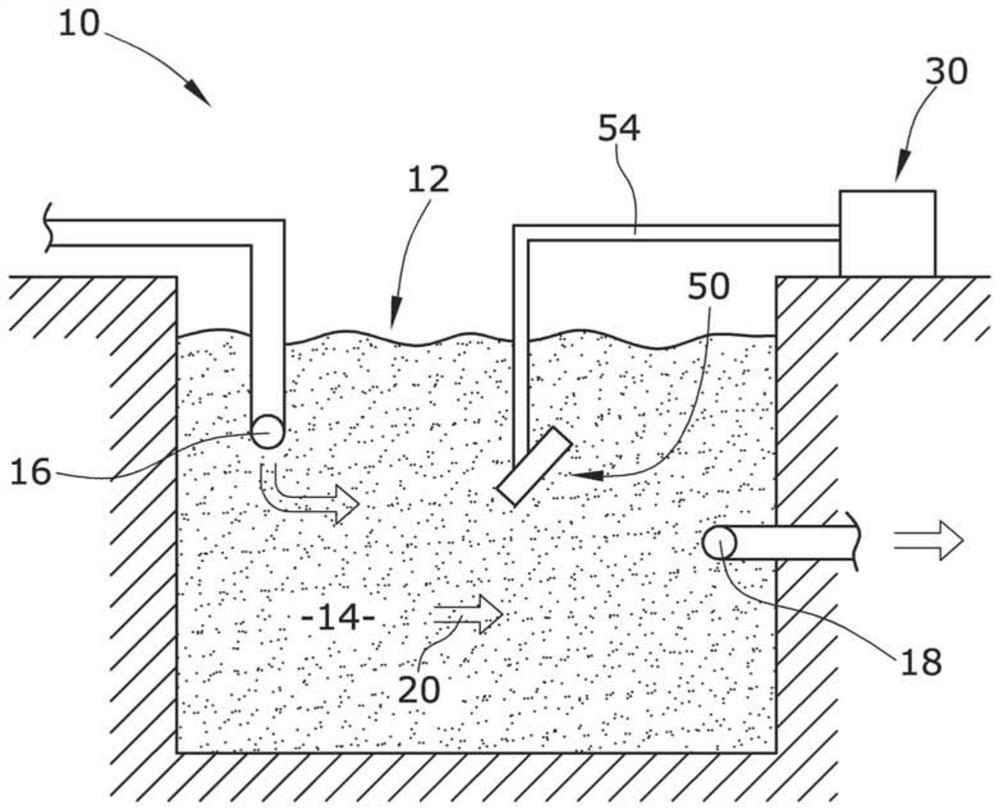

[0034] figure 1 A process water analysis device 10 for continuously analyzing water samples of wastewater 14 is schematically shown. Wastewater 14 flows continuously into a primary wastewater tank 12 through a tank inlet 16 and out of the wastewater tank 12 through a tank outlet 18, thereby creating a total waste water within the wastewater tank 12 between the inlet 16 and the outlet 18 Stream 20. Process water analysis device 10 is configured for quasi-continuous determination of one or more analytes (eg, ammonium and / or phosphate) of wastewater 14 and may be part of a wastewater treatment facility.

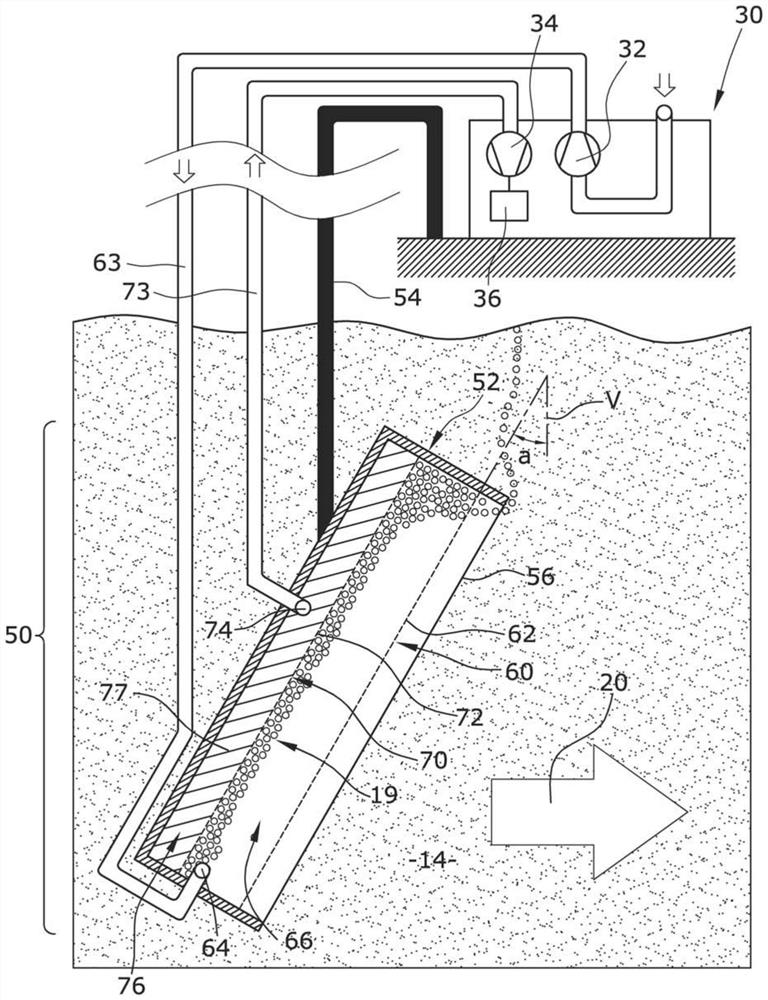

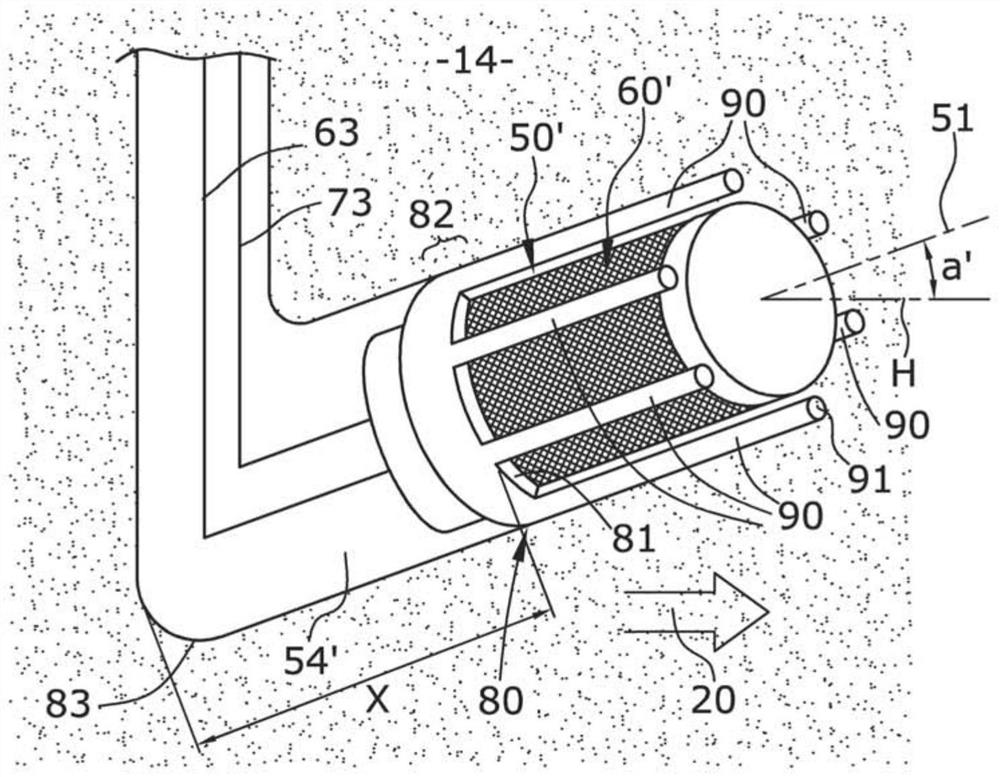

[0035] The process water analysis device 10 basically includes a water sampling immersion probe 50 that is submerged into the wastewater 14 and held and positioned by a rigid holding structure 54 . The immersion probe 50 is fluidly and electronically connectable to a landside control unit 30 comprising a sample pump 34 , an air pump 32 for aeration and a water analysis device ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap