Beam side formwork trepanning device

A technology of beam side molds and drills, which is applied in the direction of boring/drilling, drilling/drilling equipment, portable drilling rigs, etc. It can solve the problems of inconsistent high and low positions, inconvenient operation, and low operating efficiency, and achieve high and low Consistent position, convenient operation, saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

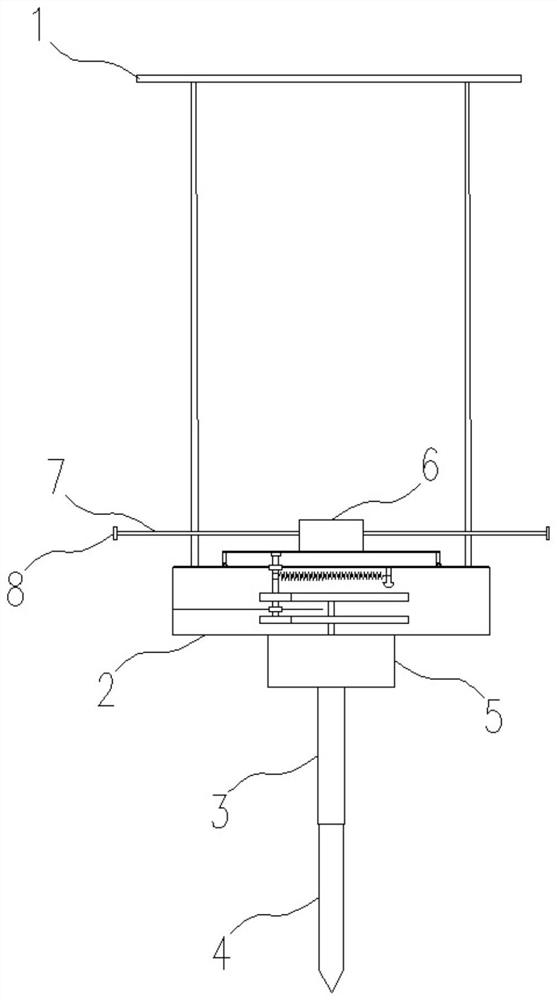

[0021] see Figure 1-4 As shown, a beam side formwork opening device includes a bidirectional drilling mechanism, a handle 1 and a support rod.

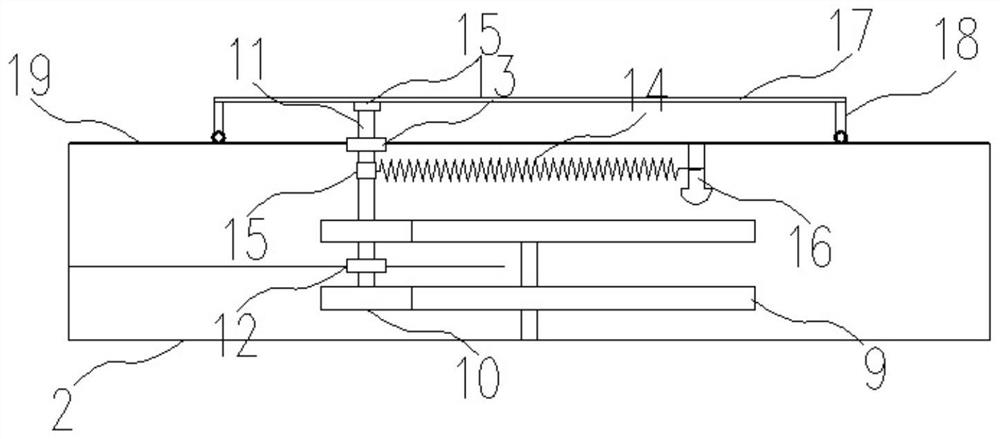

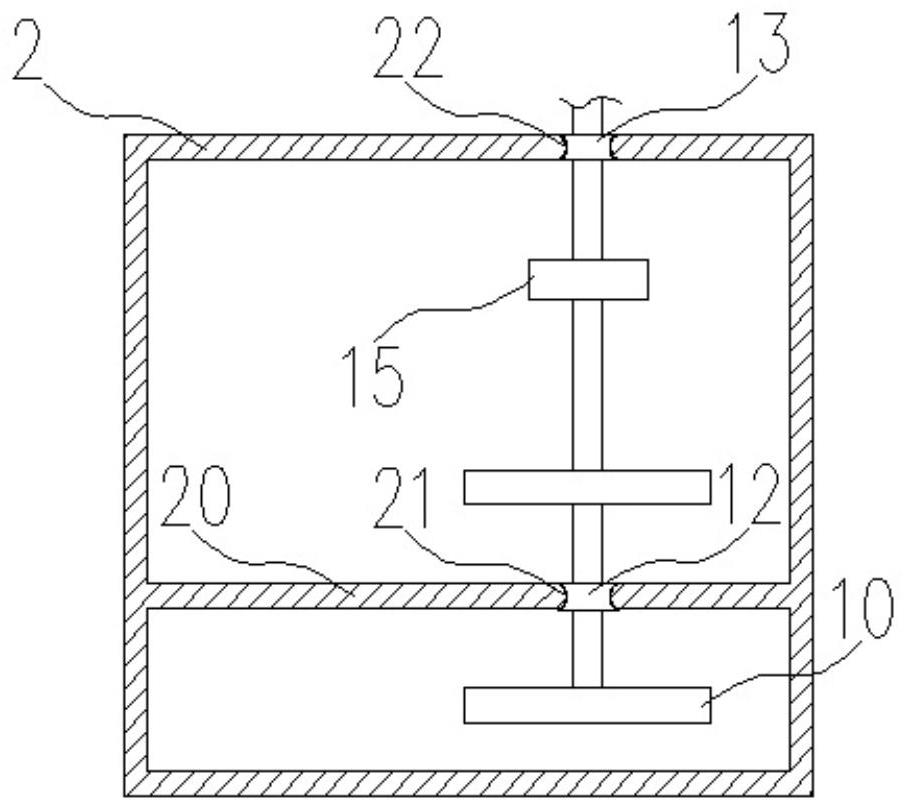

[0022] Wherein, the bidirectional drilling mechanism includes a main body 2, a driver 5, an eccentric gear 9, a concentric gear 10, a shaft roller 11, a spring 14, a flat plate 17 and a bidirectional drill. The two-way drilling mechanism can realize opposite sequential drilling, and its specific structure is as follows:

[0023] The main body 2 is a square shell structure and is provided with a first chute 22 on its top or bottom surface. A vertical plate 20 is provided in the inner cavity of the main body 2. The vertical plate 20 is provided with a chute that is flush with the first chute 22. The second chute 21;

[0024] The driver 5 is a driving motor, and the driver 5 is fixedly arranged on the end face opposite to the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com