V-shaped injection hydraulic oil way of injection molding machine

A technology of injection liquid and injection molding machine, which is applied in the direction of mechanical equipment, servo meter circuit, fluid pressure actuation device, etc. It can solve the problems that the movement speed is difficult to maintain stable and reliable, the oil cylinder of the seat and the storage screw fall, etc. The effect of smooth movement and improved position holding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

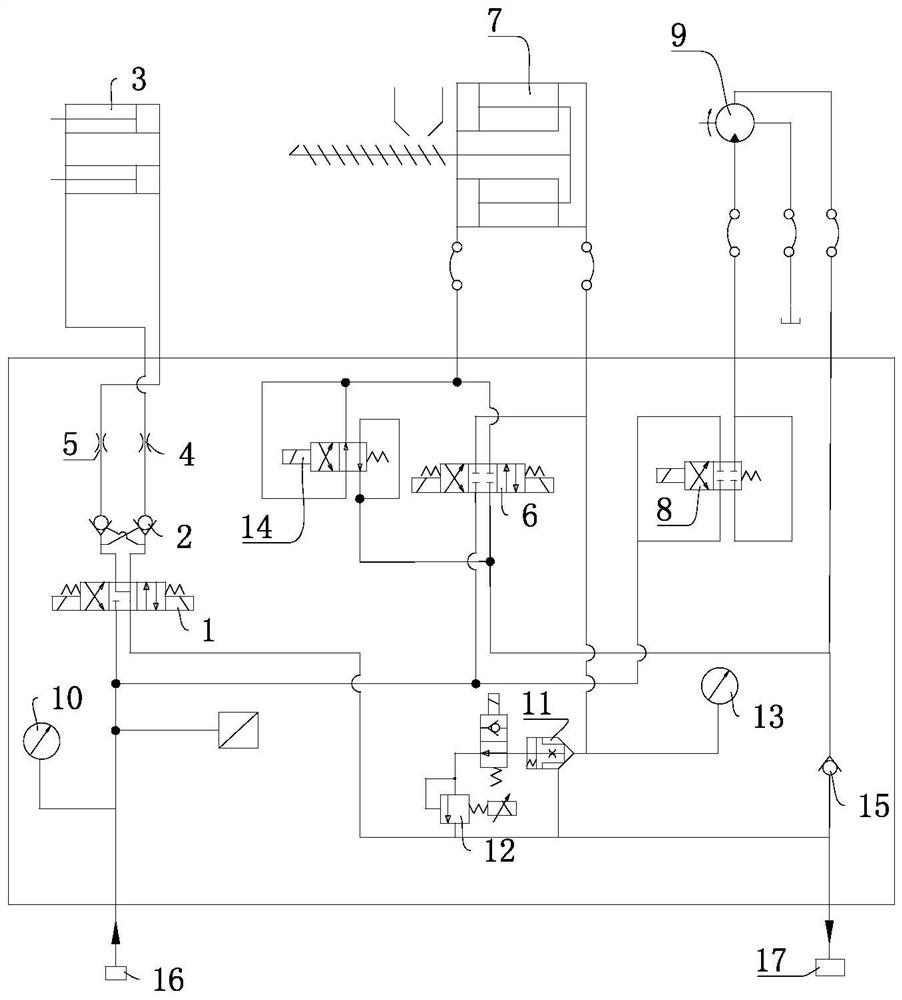

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the invention is not limited to these embodiments.

[0023] Such as figure 1 As shown, a V-shaped injection hydraulic oil circuit of an injection molding machine includes a system pressure oil inlet 16, an oil return port 17, a platform oil circuit, an injection oil circuit, and a material storage oil circuit. When the injection molding machine starts to work, the seat oil circuit Control the movement of the injection seat. When the injection seat moves to the preset position, that is, when the barrel touches the feed port, the injection oil circuit controls the oil cylinder of the seat platform to start the injection action. After the injection is completed, the injection oil circuit controls it to start injection. At the same time, the storage oil circuit controls the storage moto...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap