Ultrasonic oil-water interface detection system based on large oil storage tank

An oil-water interface and oil storage tank technology, which is used in measuring devices, liquid level indicators, engine lubrication, etc., can solve problems such as inaccurate judgment of oil-water interface, achieve simple debugging, ensure real-time control, and strong applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

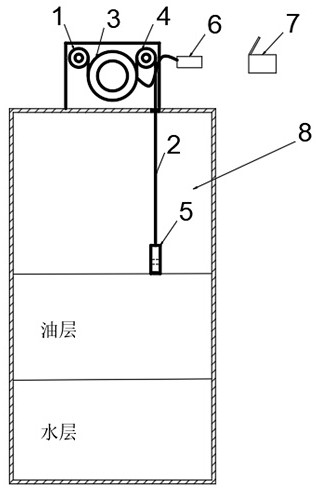

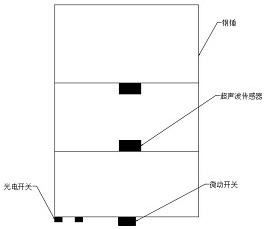

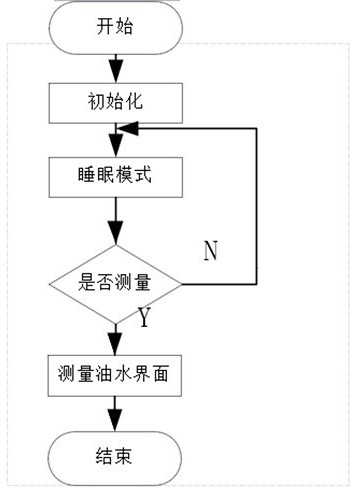

[0014] An ultrasonic oil-water interface detection system based on a large petroleum storage tank in this embodiment includes a motor and a reel 1, the motor is connected to the reel, and a communication and power cable 2 is wound inside the reel , the Hall sensor wheel 3 is connected with the guide wheel 4. The motor and the winding wheel 1 are connected to the oil-water interface detection device 5 through the guide wheel 4 through the cable 2 . The oil-water interface detection device 5 mainly includes an ultrasonic sensor, a steel hammer float, a photoelectric switch and a micro switch, and the ultrasonic sensor is arranged inside the steel hammer float; the bottom of the oil-water interface detection device 5 is provided with a photoelectric switch; The bottom of the interface detection device 5 is provided with a micro switch, and the data display device 6 is fixed outside the system. The wireless device 7 is placed outside the large oil storage tank 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com