Motor performance testing device with torsion adjusting function

A torque adjustment and testing device technology, applied in motor generator testing, measuring devices, measuring device casings, etc., can solve the problems of motor problems that cannot be found in time, invariable torque load, and less data, and avoid inaccurate testing. Avoid high temperature and reduce the effect of friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

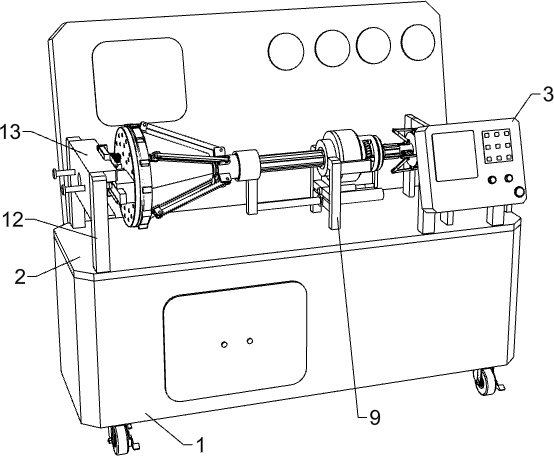

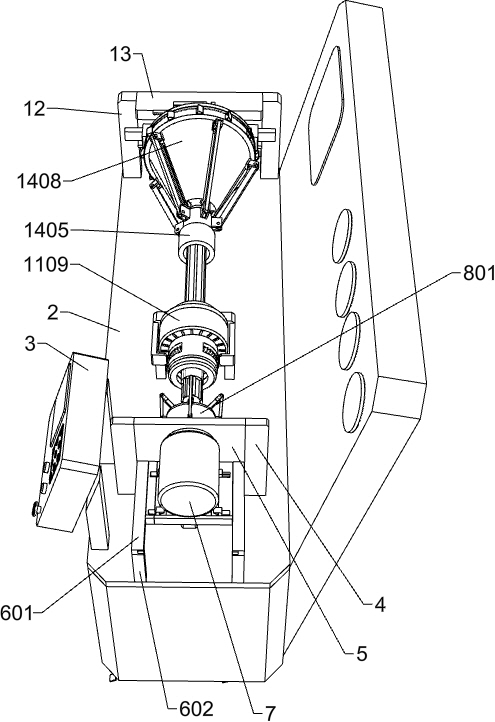

[0030] A motor performance testing device with torque adjustment function, such as Figure 1-Figure 12 As shown, it includes a support frame 1, a support plate 2, a control panel 3, a first fixing bar 4, a first fixing plate 5, a fixing mechanism, a tightening mechanism, a third fixing bar 9, a bearing 10, a protection mechanism, and a fourth fixing Bar 12, groove plate 13 and torsion adjustment mechanism, the upper end of support frame 1 is fixedly connected with support plate 2, and control panel 3 is installed on the right front part of the upper surface of support plate 2, and the front and rear of the upper surface of support plate 2 are fixed respectively. The first fixing bar 4 is connected, and the first fixing plate 5 is fixedly connected between the inner surfaces of the two first fixing bars 4. The middle part of the first fixing plate 5 is provided with a circular rotation groove for fixing the motor 7 to be tested. The fixing mechanism is arranged on the right sid...

Embodiment 2

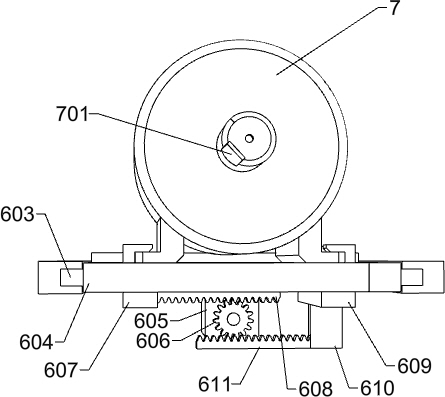

[0033] On the basis of Example 1, such as Figure 2-Figure 4 As shown, the fixing mechanism includes an electric sliding rail 601, a second fixing bar 602, an electric sliding bar 603, a first sliding plate 604, a servo motor 605, a first gear 606, a first clamping frame 607, and a first rack 608. , the second clamping frame 609, the first fixed block 610 and the second rack 611, there are two electric slide rails 601 in total, and the two electric slide rails 601 are respectively affixed to the front and rear parts of the first fixed plate 5 on the right side , the two electric slide rails 601 are electrically connected to the control panel 3 respectively, the right ends of the two electric slide rails 601 are fixedly connected with the second fixing strips 602 respectively, and the two second fixing strips 602 are fixedly connected to the upper right side of the support plate 2 respectively. The two electric slide rails 601 are slidably connected with an electric sliding bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com