Optical proximity correction mask method based on adaptive hybrid conjugate gradient descent

A technology of optical proximity correction and conjugate gradient, which is applied in optics, components for photomechanical processing, and photomechanical equipment, etc., to achieve the effect of excellent mask quality, large solution space, and resistance to process deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The technical solution of the present invention will be described in detail in conjunction with the accompanying drawings and specific examples.

[0077] Adaptive mixed conjugate gradient decreased optical approximation mask method, including steps as follows:

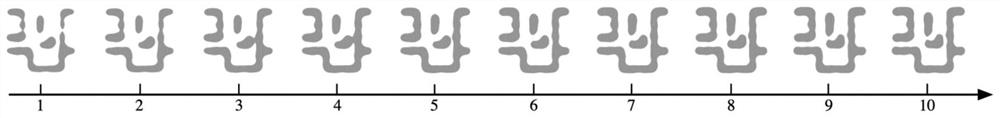

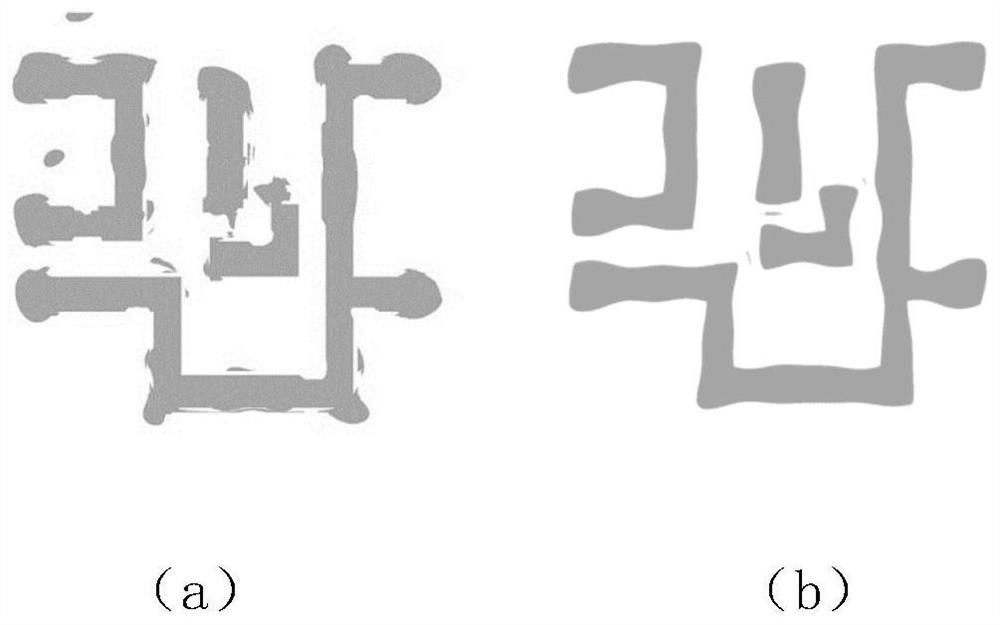

[0078] Step 1, enter the target picture z t ,like figure 1 Strun, lithography 1 , ..., h k And corresponding weight coefficient μ 1 , ..., μ k ;

[0079] Step 2, initialization;

[0080] Step 2.1, the mask version is initialized to be with the target picture Z t The same shape, and calculate the initial level set function φ 0 , Calculate φ 0 Geometric gradient Photoresist model lithography intensity threshold TH I = 0.225.

[0081] Step 2.2 After the photolithography simulation is obtained, the initial loss function f is obtained. 0 , Calculate the initial loss function gradient g 0 ;

[0082] F = αf epe + βf pvb

[0083] Where f is an optimized loss function, α, β are EPE loss functions, PVBAND loss function; to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com