Finished product forming integrated device for meat food processing and forming method

A technology for meat products and finished products, applied in the direction of meat processing, application, meat extrusion, etc., can solve the problems of inconvenient demoulding, achieve the effects of convenient demoulding, improve practicability, and reduce resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

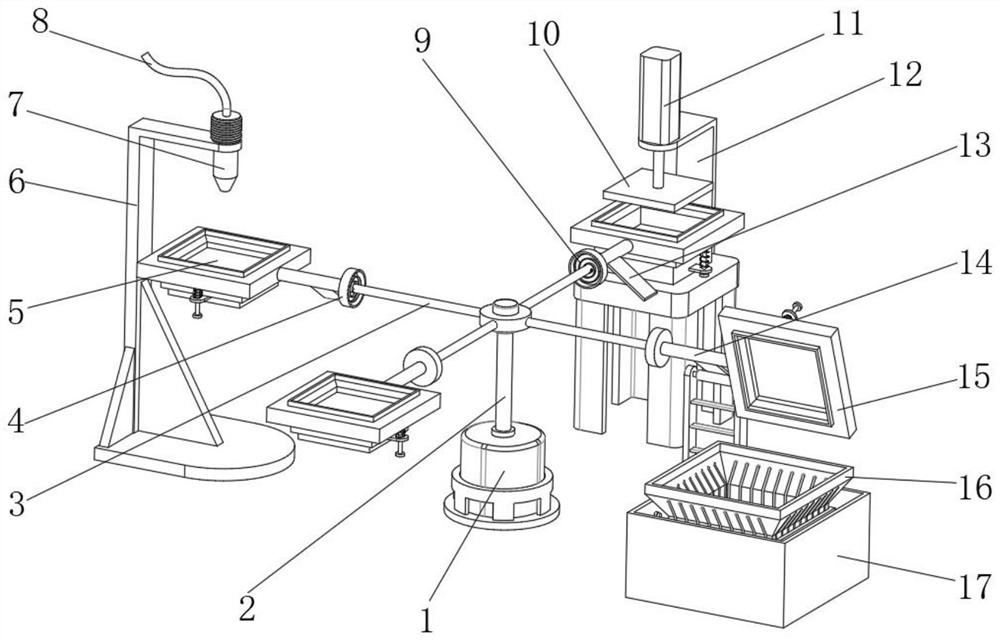

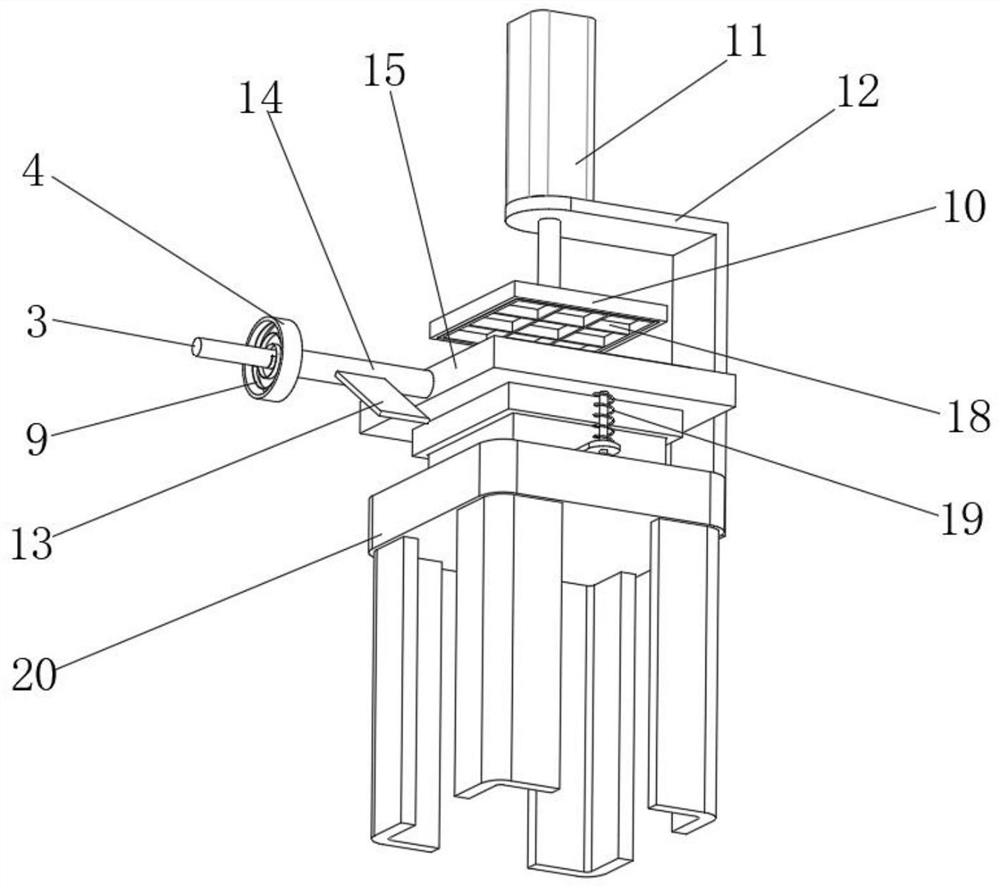

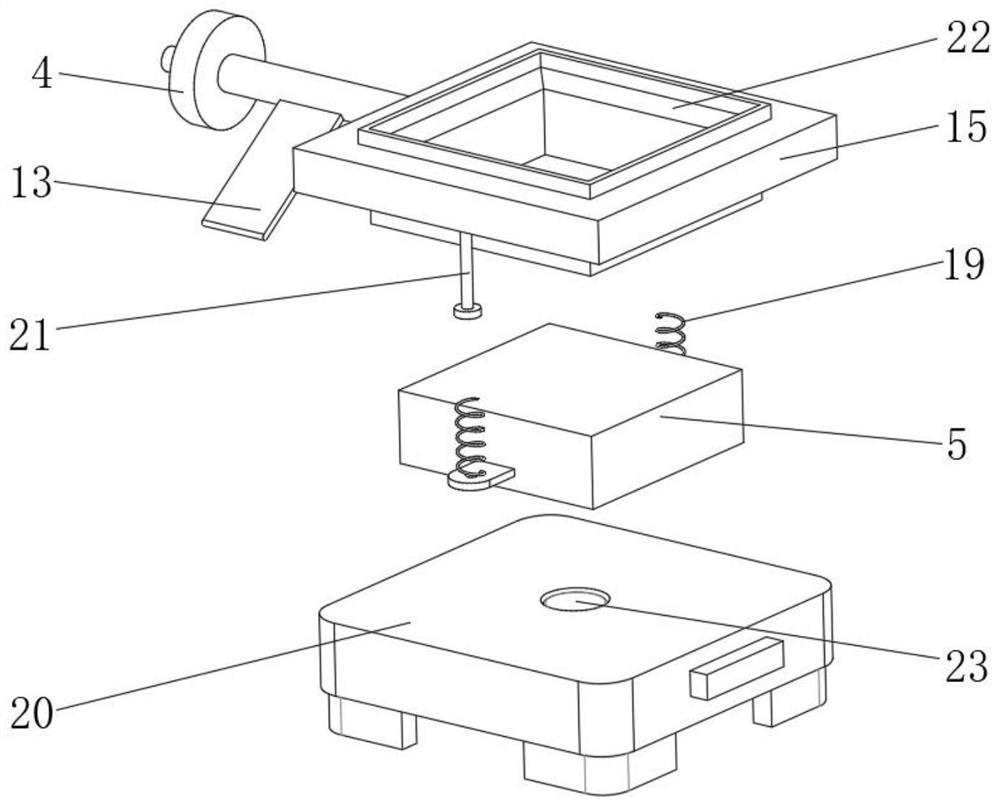

[0039] An integrated device for forming finished products for meat food processing, such as Figure 1-6As shown, it includes a rotating motor 1, the output end of the rotating motor 1 is rotatably connected with a rotating main shaft 2, and the top side wall of the rotating main shaft 2 is welded with evenly distributed support rods 3, and one end of the support rod 3 is provided with a bearing seat 15. A cavity 22 transparent up and down is arranged in the bearing seat 15, and the inner wall of the cavity 22 is slidably connected with a bottom plate 5, and the top of the bottom plate 5 and the inner wall of the cavity 22 form a space for accommodating meat; the bottom of the bearing seat 15 A jacking spring 19 is installed between the outer wall and the outer wall on both sides of the base plate 5, the outer wall of the bottom of the base plate 5 is provided with a second magnetic block 24 through a holder 25, and a supporting platform 20 is provided on one side of the rotatin...

Embodiment 2

[0047] An integrated device for forming finished products for meat food processing, such as figure 1 As shown, in order to facilitate the processing of food into different shapes; the present embodiment makes the following improvements on the basis of embodiment 1: the inner wall of the bottom of the extrusion plate 10 is fixed with a replaceable mold base 18 by screws; by setting the mold base 18 According to actual needs, the mold base 18 of the corresponding shape can be selected and installed in the extrusion plate 10, so that the food can be processed into different shapes during pressing, which improves the practicality.

Embodiment 3

[0049] A method for forming a finished product for meat food processing, comprising the steps of:

[0050] S1: Install the corresponding mold base 18 to the bottom of the extruded plate 10 according to the requirement;

[0051] S2: supply the meat ingredients through the delivery pipe 8, and then output them into the cavity 22 through the output head 7;

[0052] S3: the rotation motor 1 controls the rotation of the rotation spindle 2, and drives the bearing seat 15 with meat ingredients to move to the bottom of the extrusion plate 10;

[0053] S4: Control the operation of the hydraulic cylinder 11, use the extrusion plate 10 to press and form the meat ingredients, and then reset the hydraulic cylinder 11;

[0054] S5: The rotating motor 1 controls the rotation of the rotating main shaft 2, and transports the bearing seat 15 to the top of the storage box 16. During this period, based on the linkage between the linkage plate 13 and the linkage rod 27, the bearing base 15 unload...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com