Filter detection and maintenance device of molecular sieve oxygen generator and molecular sieve oxygen generator thereof

A maintenance device and filter technology, which is applied in the field of oxygen generators, can solve the problems of short replacement cycle, economic loss, easy dust accumulation, etc., achieve reliable and stable working effect, reduce use cost, and reduce the use of consumables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

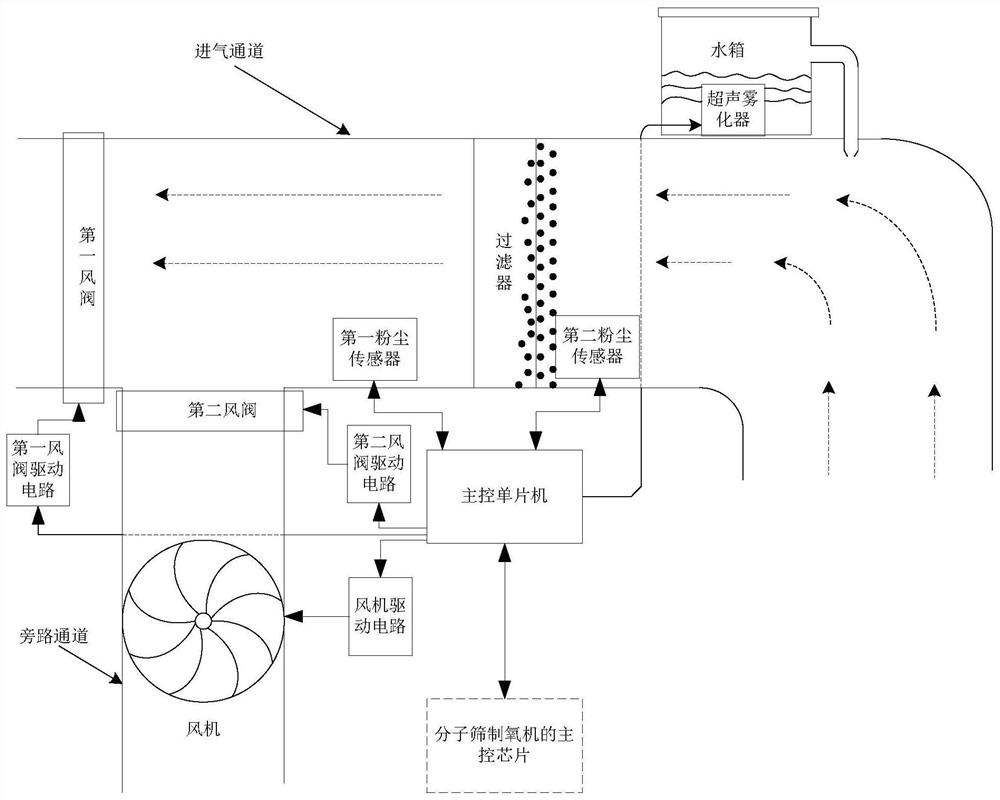

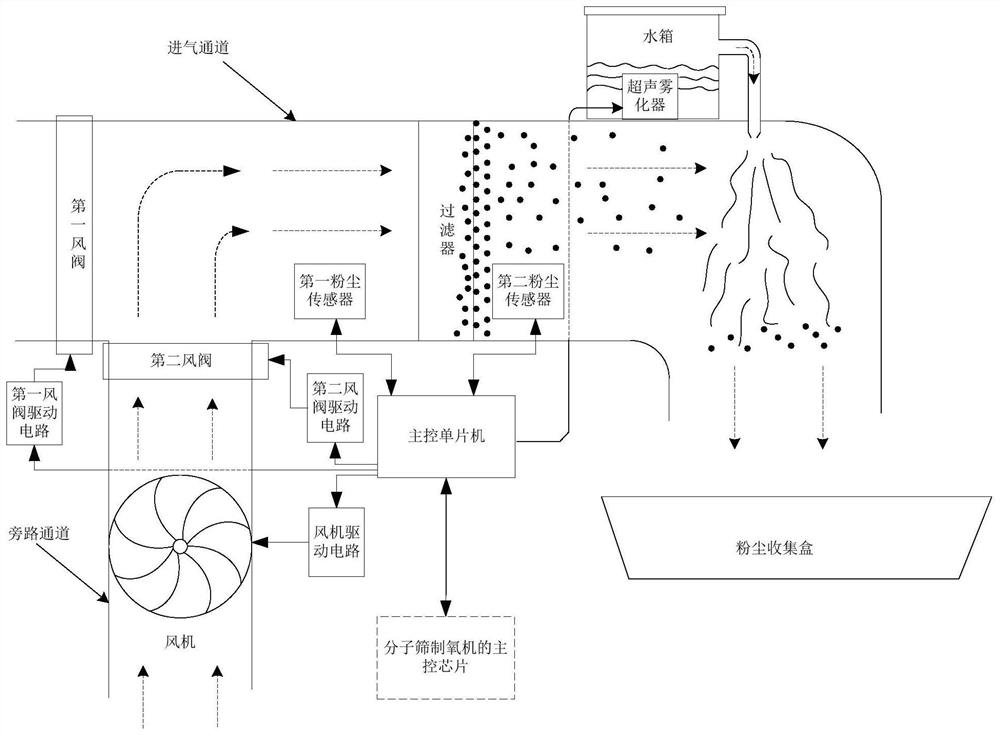

[0047] Such as figure 1 As shown, a filter detection and maintenance device for a molecular sieve oxygen generator provided by an embodiment of the present invention includes an air intake channel, a filter installed in the air intake channel, a first dust sensor, and a second dust sensor, which communicate with the The bypass channel on the side wall of the intake channel, and the fan installed in the bypass channel;

[0048] The two ends of the air inlet passage are the air inlet end and the air outlet end respectively, the filter is installed in the middle between the air inlet end and the air outlet end, and the first dust sensor is installed between the filter and the air outlet end of the air inlet passage Between, the second dust sensor is installed between the filter and the intake end of the air intake channel, the first dust sensor and the second dust sensor are used to detect the dust concentration in the space on both sides of the filter respectively;

[0049] The o...

Embodiment 2

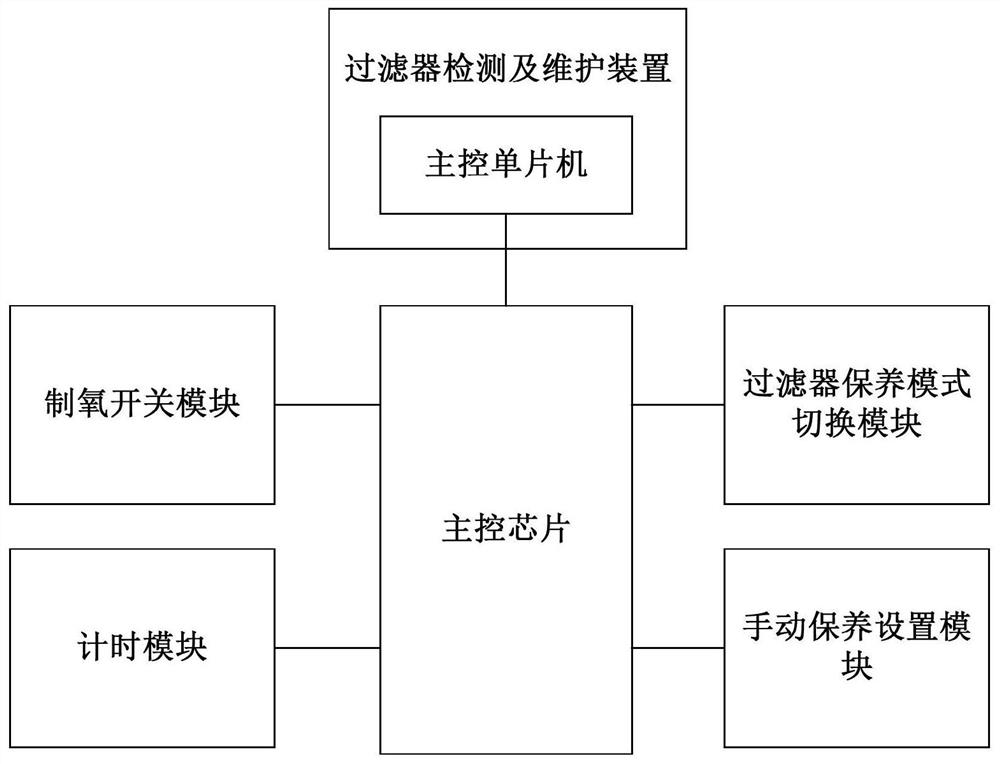

[0067] Such as Figure 2 to Figure 4 As shown, a molecular sieve oxygen generator provided by the embodiment of the present invention includes the filter detection and maintenance device described in Embodiment 1, and also includes a main control chip, an oxygen generation switch module, a filter maintenance mode switching module, and a timing module and manual maintenance setting modules. The main control chip is communicated with the main control single-chip microcomputer of the filter detection and maintenance device; the oxygen production switch module, the filter maintenance mode switching module, the timing module and the manual maintenance setting module are respectively connected with the main control chip.

[0068] Among them, the oxygen generation switch module is used to control the oxygen generation function of the molecular sieve oxygen generator to turn on or off;

[0069] The filter maintenance mode switching module is used for the user to switch and select dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com