Chain type feeding and label pressing device for nickel starting sheets

A starter sheet and chain-type technology, which is applied in the field of labeling devices and nickel starter sheet chain feeding and labeling devices, can solve the problem of occupying a large amount of human resources and site resources, failing to meet the requirements of automated production, and high labor intensity. problem, to achieve the effect of good positioning effect, reasonable design and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

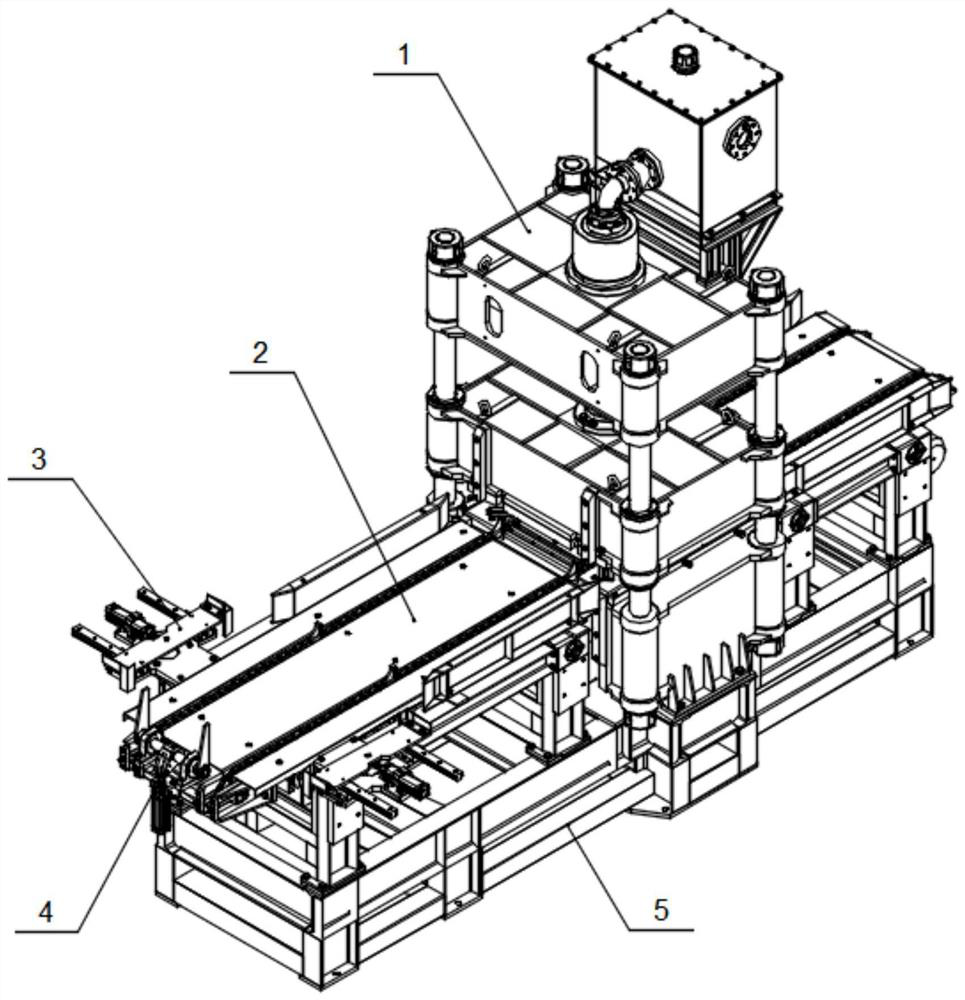

[0040] Such as figure 1 As shown, the present embodiment provides a chain feeding and marking device for nickel starting plates, including a hydraulic press 1, a chain conveying assembly 2, a plate centering assembly 3, a pressing plate assembly 4 and a base 5; the plate centering The number of components 3 is two and installed symmetrically on both sides of the front end of the chain conveyor component 2, the hydraulic press 1 is installed in the middle of the chain conveyor component 2, and the pressure plate component 4 is installed on the front end of the chain conveyor component 2, Both the hydraulic press 1 and the chain conveyor assembly 2 are installed on the base 5 .

Embodiment 2

[0042] Such as Figure 2-4 As shown, this embodiment is further optimized on the basis of embodiment 1, specifically:

[0043] Wherein, the hydraulic press 1 includes a lower fixing seat 8, a press slider 9, a pull rod 10, an oil cylinder 11, an upper fixing seat 12, a mounting frame 13, a high-pressure ball valve 14, an oil tank 15, a 90° elbow 16, a large nut 17, Corner column 18, upper mold holder 19, upper mold 20, lower mold 21, lower mold holder 22, upper mold stop iron 24, baffle assembly 25, lower mold stop iron 26, limit switch mounting frame 27 and eyebolt screw 28;

[0044] The lower fixing base 8 is installed on the base 5, the upper fixing base 12 is installed on the top of the hydraulic press 1, the press slider 9 is installed in the middle of the hydraulic press 1, and the corner post 18 is installed on the lower fixing base 8, the press slider 9, and the upper fixing base Around 12, the pull rod 10 is installed on the corner post 18, the large nut 17 is instal...

Embodiment 3

[0048] Such as Figure 5-12 As shown, this embodiment is further optimized on the basis of embodiment 1, specifically:

[0049] The chain conveying assembly 2 includes a motor 6, a driving sprocket 7, a cylinder II 23, a workbench 36, a long connecting rod 37, a side guide plate 38, a positioning hook 39, a chain 40, a short connecting rod 41, a front lifting frame 42, Motor bracket 43, driven sprocket assembly 44, rear lifting frame 45, earring seat I46, earring seat II47, lifting base assembly 48, frame body shaft 49, connecting rod 50, driving sprocket bracket 51, main drive chain 52, slave Moving sprocket I 53, driving shaft 54 and sprocket 55;

[0050] The sprocket 55 is installed on the motor 6, the motor 6 is installed on the motor bracket 43, the main transmission chain 52 is installed on the sprocket 55 and the driven sprocket I53, and the driven sprocket I53 and the driving sprocket 7 are installed on the drive shaft 54 On, driving shaft 54 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com