Device and method for preparing tetravalent uranium through electrolysis

A technology of tetravalent uranium and uranyl nitrate, which is applied in the field of electrolytic preparation of tetravalent uranium, can solve the problems of poor heat and mass transfer performance, low production efficiency, low current density, etc., and achieve slow temperature rise, convenient operation and maintenance , Reduce the effect of system resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

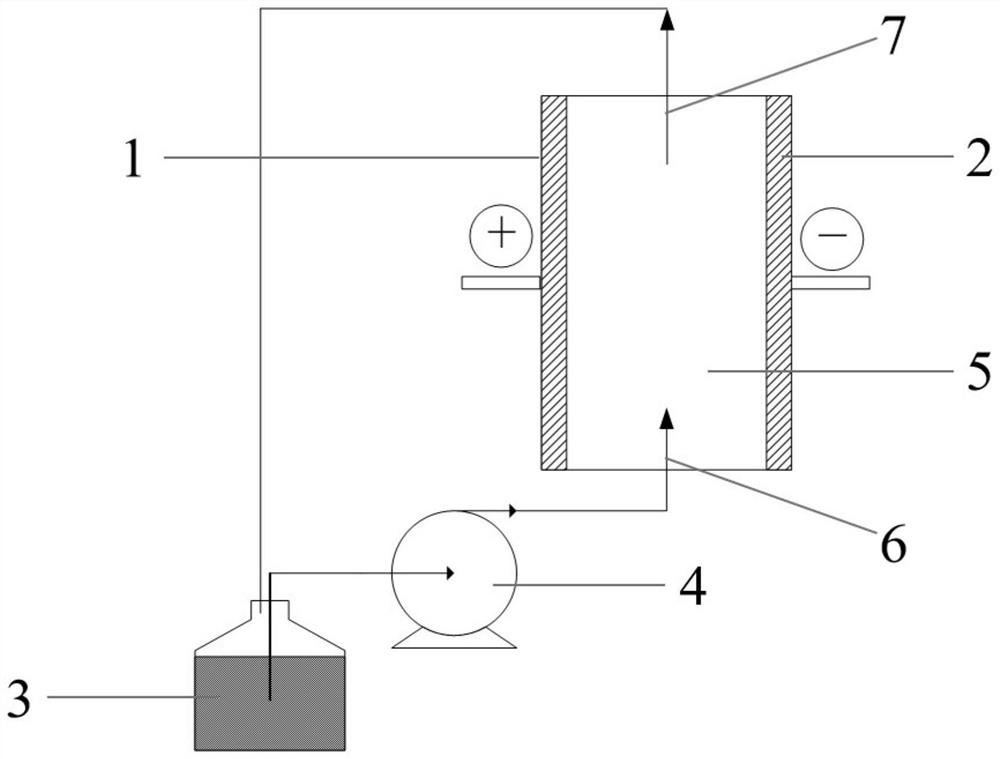

Image

Examples

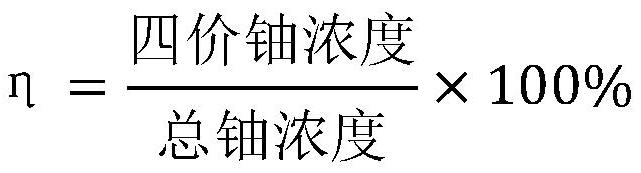

Embodiment 1

[0053] The feed liquid is continuously circulated between the feed liquid storage tank and the electrode chamber through the circulation pump. The initial feed liquid composition is: 200g / L uranyl nitrate solution (200g / L is based on the content of uranium), 3.0mol / L nitric acid solution and 1.0mol / L hydrazine solution; set the current density to 120mA / cm 2 , after electrolysis for 120 minutes, the concentration of tetravalent uranium is 165.0g / L, and the conversion rate reaches 82.5%.

Embodiment 2

[0055] The feed liquid is continuously circulated between the feed liquid storage tank and the electrode chamber through the circulation pump. The initial feed liquid composition is: 200g / L uranyl nitrate solution (200g / L is based on the content of uranium), 3.0mol / L nitric acid solution and 1.0mol / L hydrazine solution; set the current density to 80mA / cm 2 , after electrolysis for 180 minutes, the concentration of tetravalent uranium was 163.2g / L, and the conversion rate reached 81.6%.

Embodiment 3

[0057] The feed liquid is continuously circulated between the feed liquid storage tank and the electrode chamber through the circulation pump. The initial feed liquid composition is: 300g / L uranyl nitrate solution (300g / L is based on the content of uranium), 3.0mol / L nitric acid solution and 1.2mol / L hydrazine solution; set the current density to 150mA / cm 2 , after electrolysis for 125 minutes, the tetravalent uranium concentration was 252.5g / L, and the conversion rate reached 84.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com