Beer saccharification filter device using coil pipe for heating

A filter equipment and technology of beer sugar, which is applied in the field of beer brewing, can solve problems such as difficulty in keeping constant, difficulty in filtration, and decline in saccharification yield, and achieve the effects of shortening the pot time, improving flexibility, and saving filtration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

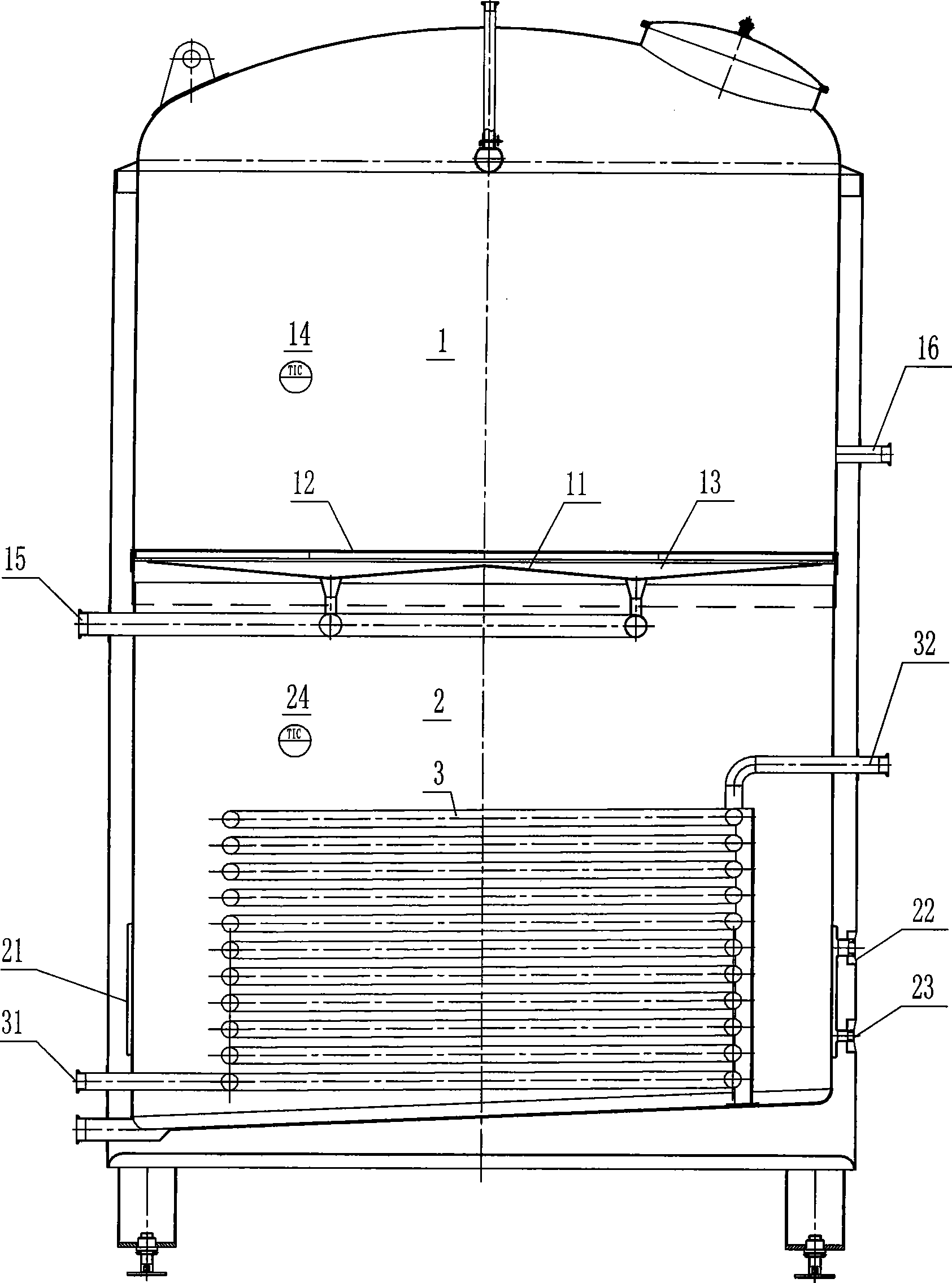

[0017] Such as figure 1 As shown, the beer saccharification and filtering equipment heated by coils is used in this embodiment, which includes a saccharification and filtration tank 1 , a hot water tank 2 and a coiled tube 3 placed in the hot water tank 2 . The saccharification lauter tank 1 and the hot water tank 2 share a top-bottom structure, that is, an integrated combination tank with the saccharification lauter tank 1 on the top and the hot water tank 2 on the bottom, and the top of the hot water tank 2 also serves as the top of the saccharification lauter tank 1. tank bottom11.

[0018] A sieve plate 12 for filtering is provided above the tank bottom of the saccharification filtration tank 1 , and a funnel-shaped wort collection area 13 is provided in the space between the tank bottom 11 and the sieve plate 12 . A first temperature measurement and control device 14 is also provided in the saccharification filter tank 1 .

[0019] The tank bottom 11 of the saccharifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com