Low-pressure small-caliber safety relief valve

A small-diameter, pressure relief valve technology, applied in the field of safety valves, can solve the problems of poor discharge pressure stability, low action sensitivity, complex structure, etc., and achieve the effects of stable discharge pressure, high opening and closing sensitivity, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

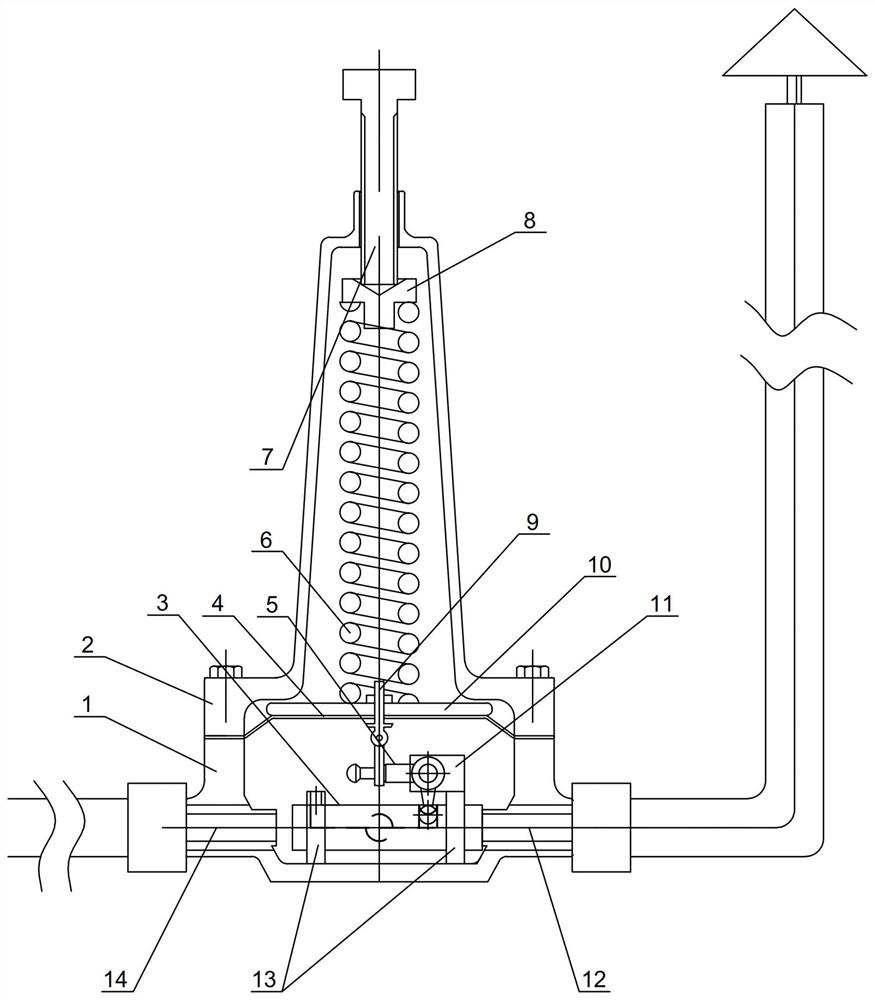

[0011] Such as figure 1 The low-pressure small-diameter safety pressure relief valve shown includes a valve body 1 and a valve cover 2. The valve cover 2 is installed on the upper end of the inner cavity of the valve body 1 by a flange. The inner cavity of the valve body 1 is connected to the inlet channel 14, the outlet channel and the pressure relief valve. The channel 12, the inlet channel 14 coincides with the center line of the pressure relief channel 12, and the center line of the outlet channel and the inlet channel 14 are perpendicular to each other. A spring pressure setting device is arranged between the upper end surface of the diaphragm 4 and the valve cover 2; the spring pressure setting device is composed of a spring 6 and an adjusting stud 7, the adjusting stud 7 is threaded on the upper end of the valve cover 2, and the spring 6 is installed on the Between the adjusting stud 7 and the sealing diaphragm 4, a spring seat 8 is set between the upper end of the spri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap