Anti-scour flow equalizing assembly, falling film evaporator and air conditioning unit

A component and anti-shock technology, applied in evaporator/condenser, refrigeration components, refrigerators, etc., to solve the problem of inability to distribute refrigerant on heat exchange coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

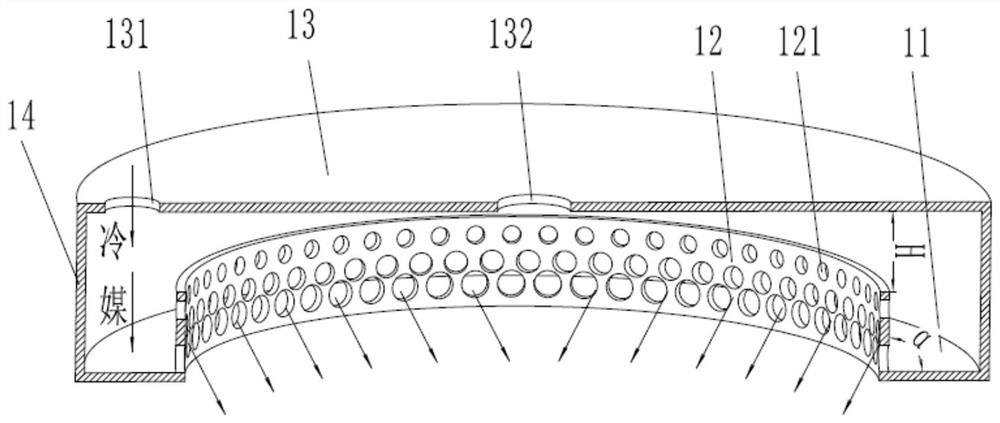

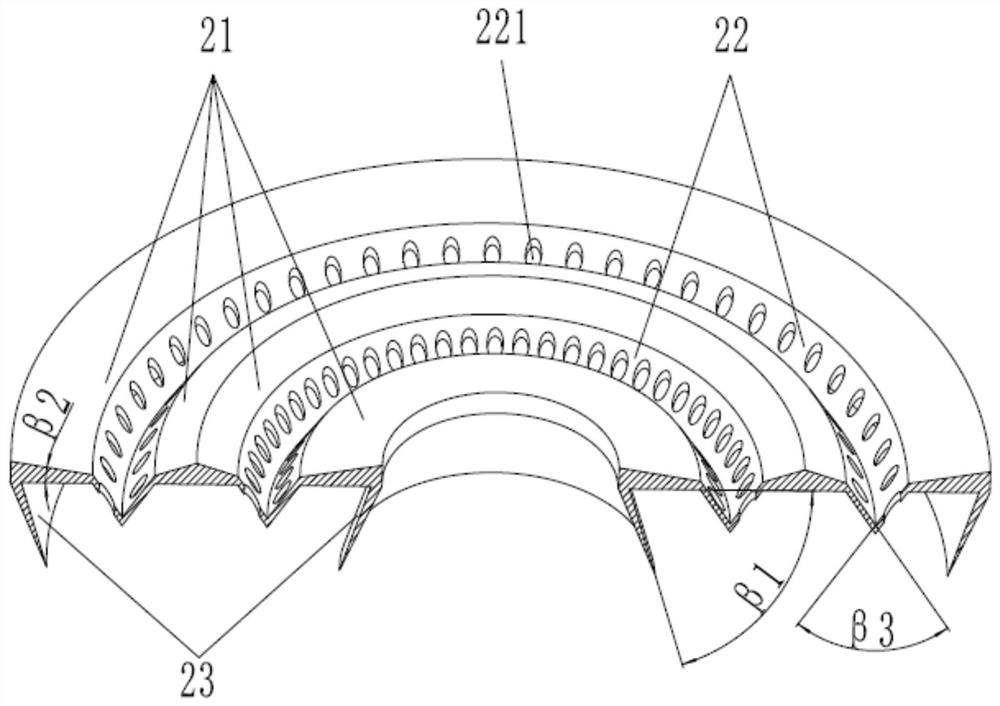

[0042] This embodiment describes in detail the anti-scouring current equalization component of the present invention.

[0043] The anti-scouring flow equalization assembly of this embodiment is used in a falling film evaporator. The anti-shock flow equalization assembly of this embodiment includes an anti-shock device 1, and the anti-shock device 1 is located below the inlet connecting pipe 3, such as figure 1 shown. Preferably, the anti-shock device 1 includes an anti-shock plate 11, a liquid separator plate 12, a top plate 13 and a side plate 14, and the anti-shock plate 11, the liquid separator plate 12 and the side plate 14 are enclosed to form an accommodating cavity, and the accommodating cavity and the inlet The connecting pipe 3 is connected, and the liquid separator plate 12 is an annular structure located in the middle of the anti-shock plate 11. There is a gap between the top of the liquid separator plate 12 and the top plate 13, such as figure 1 and figure 2 sh...

Embodiment 2

[0059] This embodiment describes the falling film evaporator of the present invention in detail.

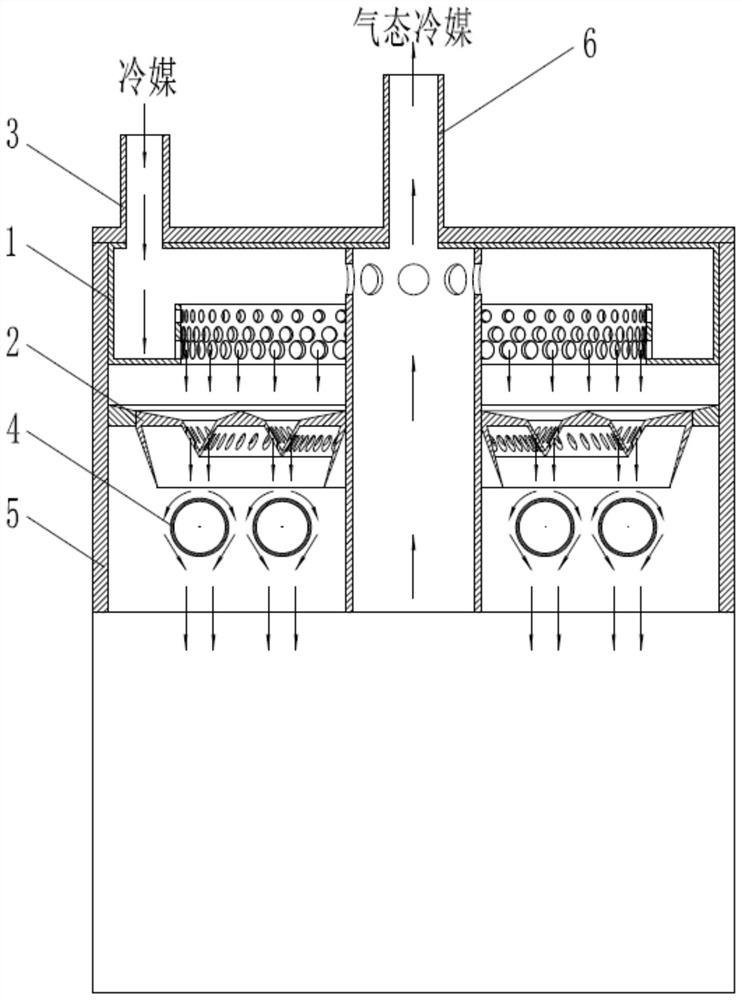

[0060] The falling film evaporator of this embodiment includes the anti-scouring flow equalizing assembly of any one of the technical solutions in embodiment 1, and the anti-scouring flow equalizing assembly is arranged between the refrigerant inlet connecting pipe 3 and the heat exchange coil 4 . Such as figure 1 As shown, the falling film evaporator of this embodiment also includes an inlet connecting pipe 3, a heat exchange coil 4, a cylinder body 5 and an outlet connecting pipe 6, wherein the inlet connecting pipe 3 and the outlet connecting pipe 6 are located above the cylinder body 5; The flow component is located in the cylinder body 5 , and the anti-scour device 1 of the anti-scour flow equalization component is located below the inlet joint 3 , and the flow equalizer 2 of the anti-scour flow equalizer component is located above the heat exchange coil 4 .

[0061] figur...

Embodiment 3

[0064] This embodiment describes the air conditioning unit of the present invention in detail.

[0065] The air conditioning unit of this embodiment includes the falling film evaporator according to any one of the technical solutions in Embodiment 2. The rest of the structure of the air conditioning unit in this embodiment can be the same as that of the prior art, and will not be repeated here. Preferably, the air conditioner unit in this embodiment is a water-cooled unit.

[0066] The air-conditioning unit of this embodiment includes the falling-film evaporator of any one of the technical solutions in Embodiment 2. Since the heat exchange efficiency and service life of the falling-film evaporator are improved, the performance of the air-conditioning unit of this embodiment is improved. Increased lifespan.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com