Sandstone aggregate mine rock mass blasting mining method

A mining method and mining rock technology, applied in blasting, ground mining, earth square drilling and mining, etc., can solve problems such as large blindness, lack of basis, and high powder ore rate, so as to reduce overall cost, reduce blindness, and reduce fine ore rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

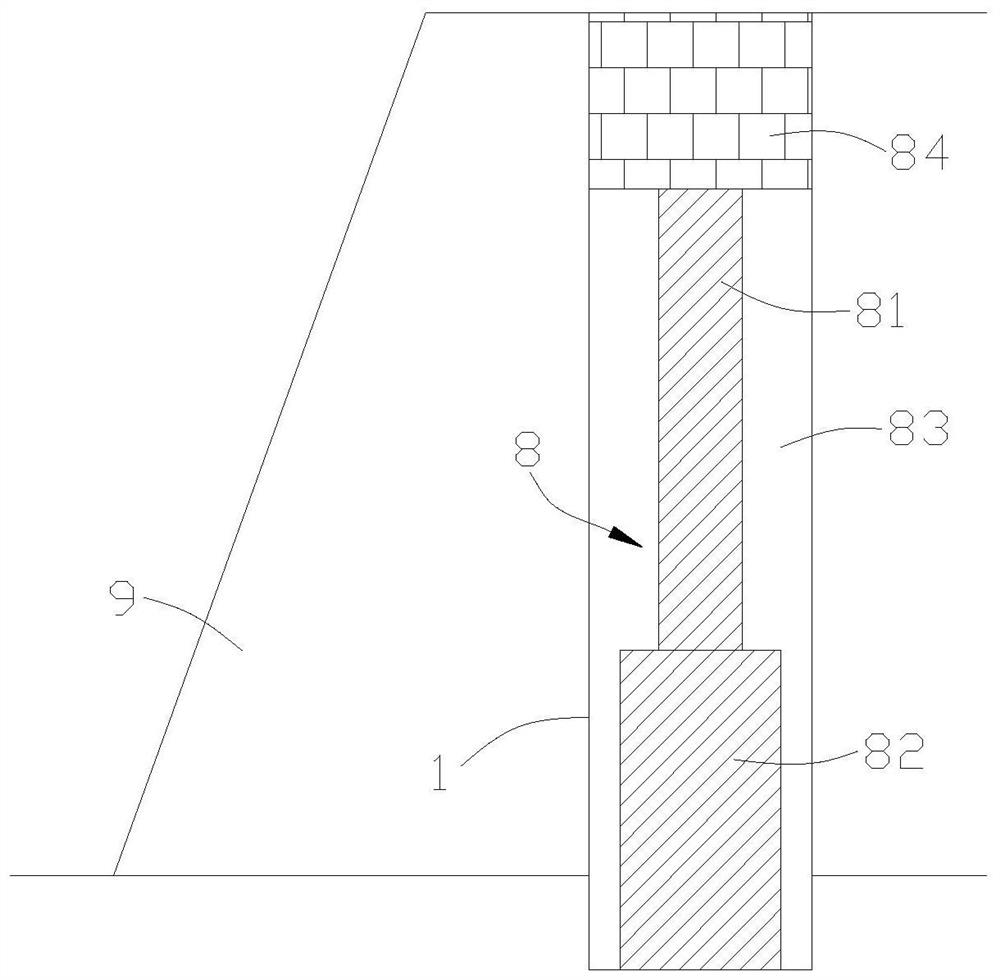

[0068] In a rock mass quarry of a large-scale sandstone aggregate mine, six indicators including rock hardness, rock type, blasting funnel volume, blasting fragmentation distribution index, crack distance, and explosive unit consumption were used to dismantle the entire quarry rock mass according to requirements. Divide the large area above 800kg, the medium area of 100kg-800kg and the small area below 100kg. And through the geological record of the rock mass structural plane of the quarry and the blasting funnel test, the blasting fragmentation zoning map of the rock mass is drawn, as shown in figure 1 . The details of rock masses in each block are as follows:

[0069] Large area: rock type is granite, rock hardness f value>12, blasting funnel volume3 , Blasting lumpiness distribution index0.45kg / m 3 , The crack spacing of the main structural plane 130°∠80° is 70-200cm, and the crack spacing of the main structural plane 60°∠60-80°>100cm.

[0070] Middle block area: the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com