Gas flow measuring device, system and method based on ultrasonic waves

A technology for gas flow and measuring device, applied in measuring device, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve problems such as complex overall structure, achieve simple installation and operation, reduce measurement error, and good practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

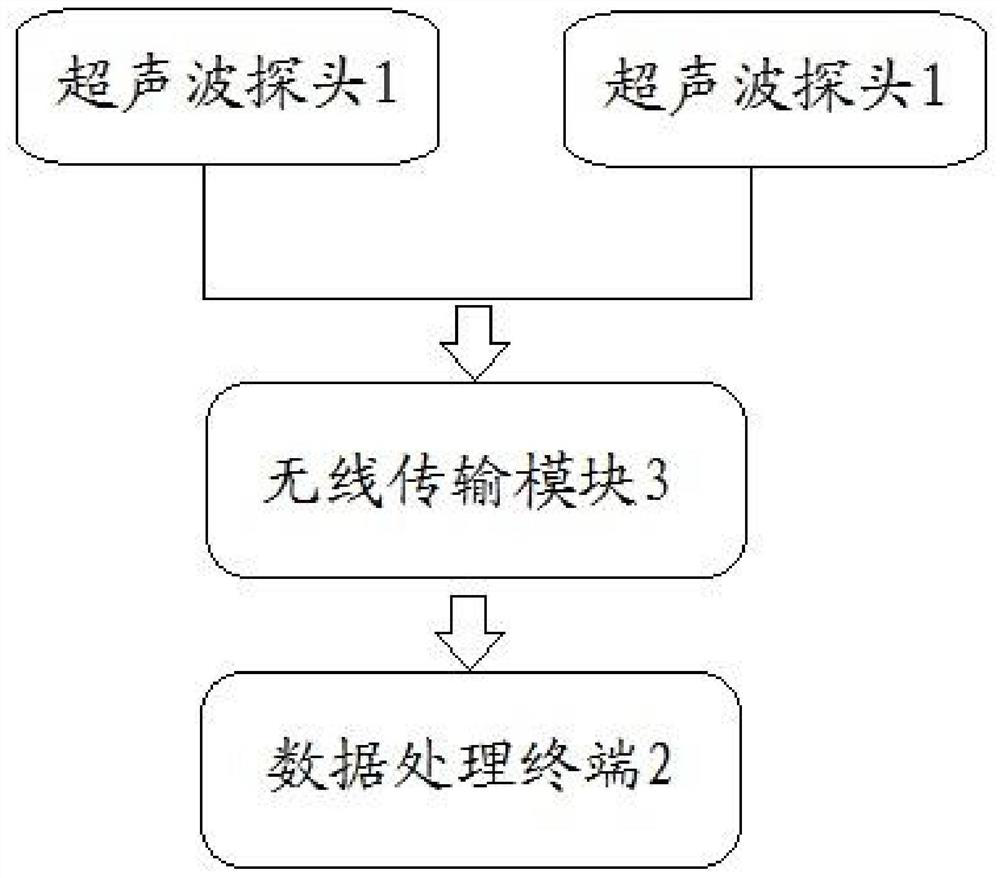

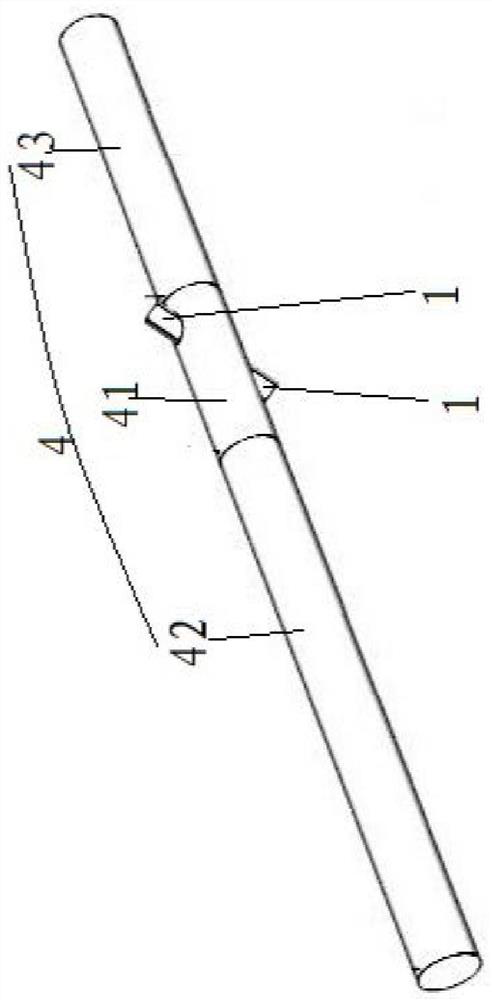

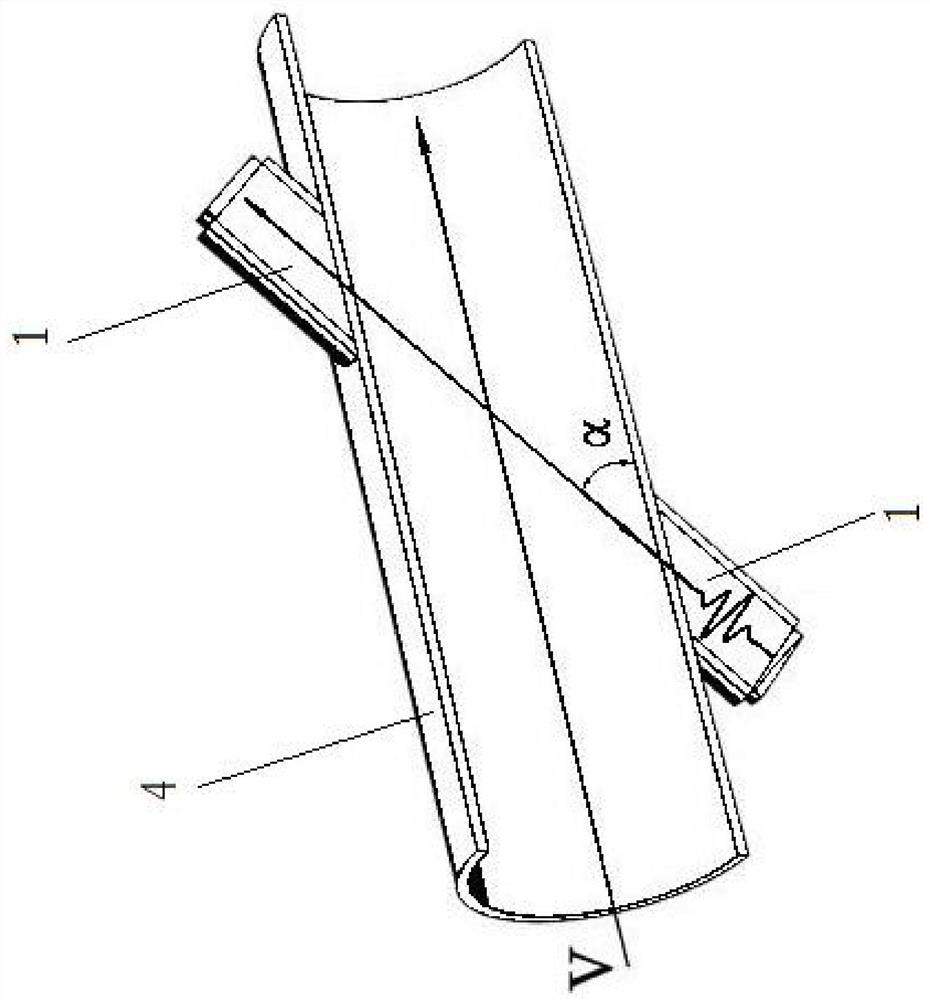

[0041] see Figure 1 to Figure 5, as shown in the legend therein, an ultrasonic-based gas flow measurement device includes a plurality of ultrasonic probes 1 for measuring the forward and countercurrent propagation times of ultrasonic waves in the gas in the pipeline and for calculating the gas flow in the pipeline. The data processing terminal 2 of the cross-sectional average flow velocity of the above-mentioned data processing terminal 2 adopts the following formula to calculate the cross-sectional average flow velocity of the gas in the pipeline:

[0042]

[0043] Among them, Q v is the cross-sectional average velocity of the gas in the pipeline; π is the circumference ratio; D is the diameter of the pipeline; c is the propagation speed of the ultrasonic wave in the gas in the pipeline; α is the installation inclination angle of the ultrasonic probe;

[0044] K is the flow rate correction coefficient,

[0045] Kc is the sound velocity correction coefficient, c0 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com