Plate strip steel convexity prediction method based on data driving and mechanism model fusion

A mechanism model, data-driven technology, applied in the direction of electrical digital data processing, special data processing applications, neural learning methods, etc., can solve the problem of reduced model prediction accuracy, large error range, and unset benchmark value of strip crown, etc. problem, to achieve the effect of narrowing the scope, improving accuracy, and strengthening the promotion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The method of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

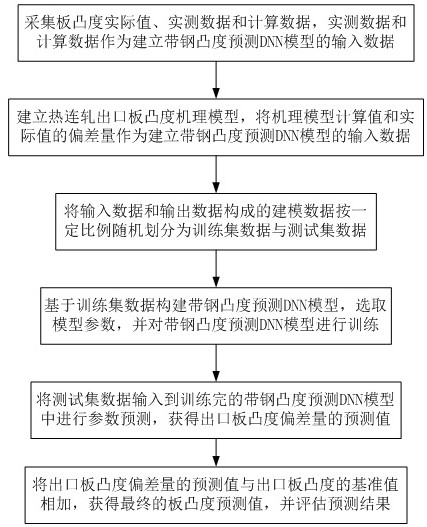

[0075] This example is based on a hot continuous rolling production line in China, and the data related to the export crown of the strip steel is used as the data established by the model. The overall process is as follows figure 1 As shown, it specifically includes the following steps:

[0076] Step 1: Collect the actual value of the crown of the exit plate, the measured data related to the crown of the hot continuous rolling production line and the crown of the exit plate, and the calculation data of the process automation level, and use the measured data and calculation data as the basis for establishing the DNN model for strip crown prediction Input data, the step 1 is specifically:

[0077] Step 1.1: Select the eight-stand continuous rolling production line for finishing rolling, and determine the following influencing factors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com