Control method and system based on material pile layering three-dimensional real-time model

A control method and control system technology, which is applied in the field of intelligent equipment in coal stockyards, can solve problems such as the inability to reflect the morphological characteristics of the stockpile, and the inability to match the stacker-reclaimer equipment control method, etc., to achieve the goal of improving reliability and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings.

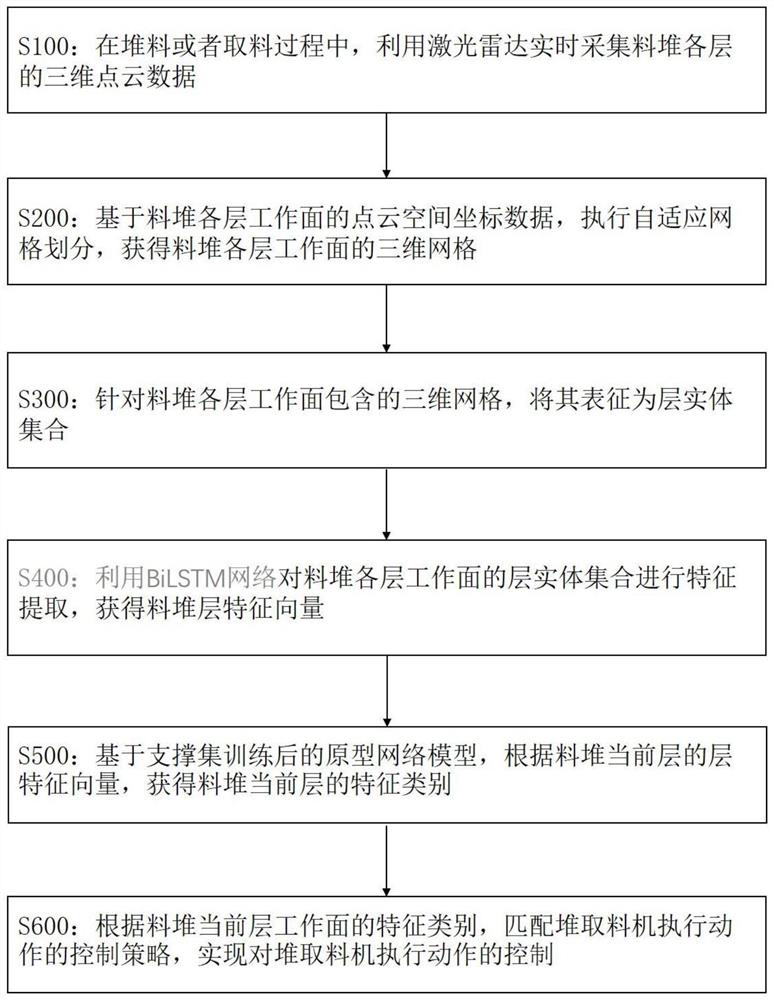

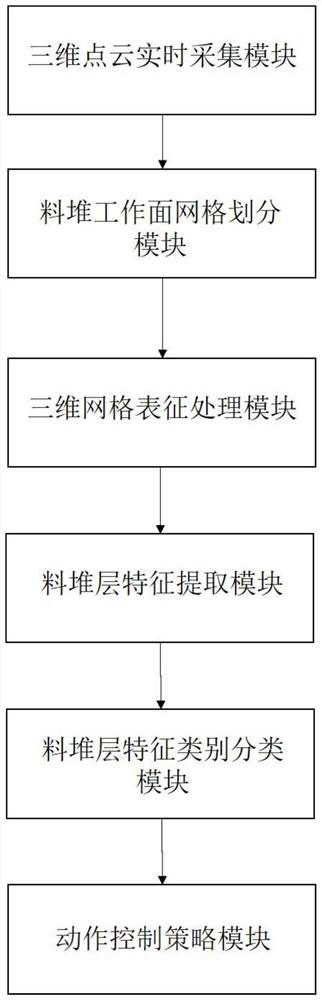

[0053] The present invention provides a control method based on a three-dimensional real-time model of stockpile layering, and its specific process is as follows figure 1 shown, including:

[0054] S100: During the process of stockpiling or retrieving, use the laser radar to collect the 3D point cloud data of each layer of the stockpile in real time.

[0055] Install lidar at appropriate locations on the bucket wheel stacker-reclaimer. When the stacker-reclaimer is stacking or reclaiming the material pile, the working surface is raised or lowered layer by layer. Therefore, the laser radar can be used to perform three-dimensional scanning on each layer of the material pile to realize the material pile Real-time collection of point cloud space coordinate data of each layer of working face.

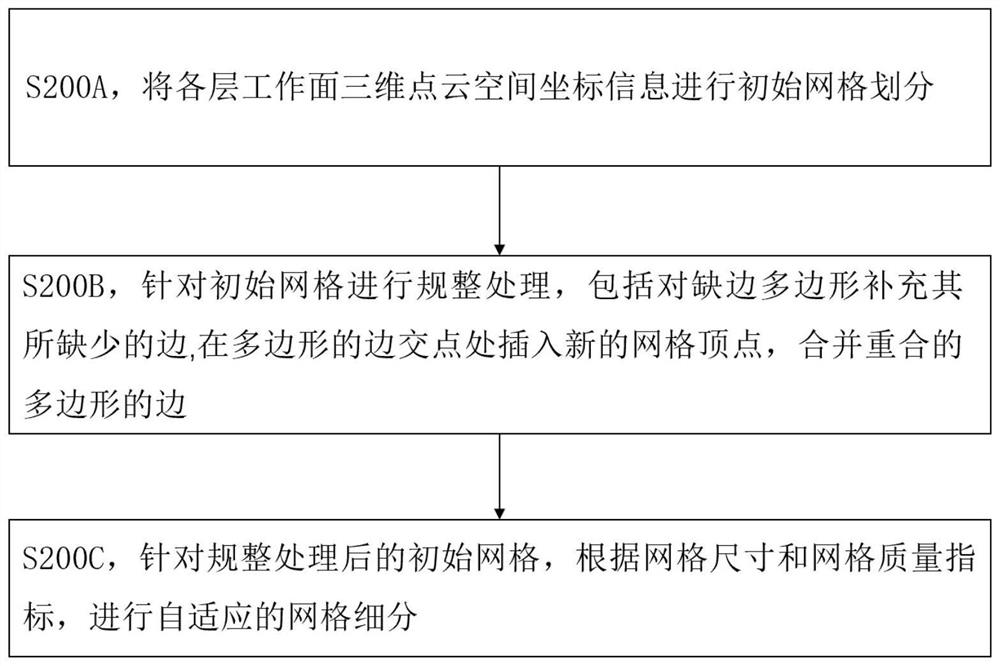

[0056] S200: Based on the point cloud spatial coordinate data of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com