Vacuum refining waste gas treatment system and vacuum refining waste gas treatment method

A waste gas treatment and vacuum refining technology, which is applied in chemical instruments and methods, separation methods, transportation and packaging, etc., can solve problems such as dust ingress, equipment shutdown, and gas temperature rise, and achieve the effect of protecting the vacuum pump and operating safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

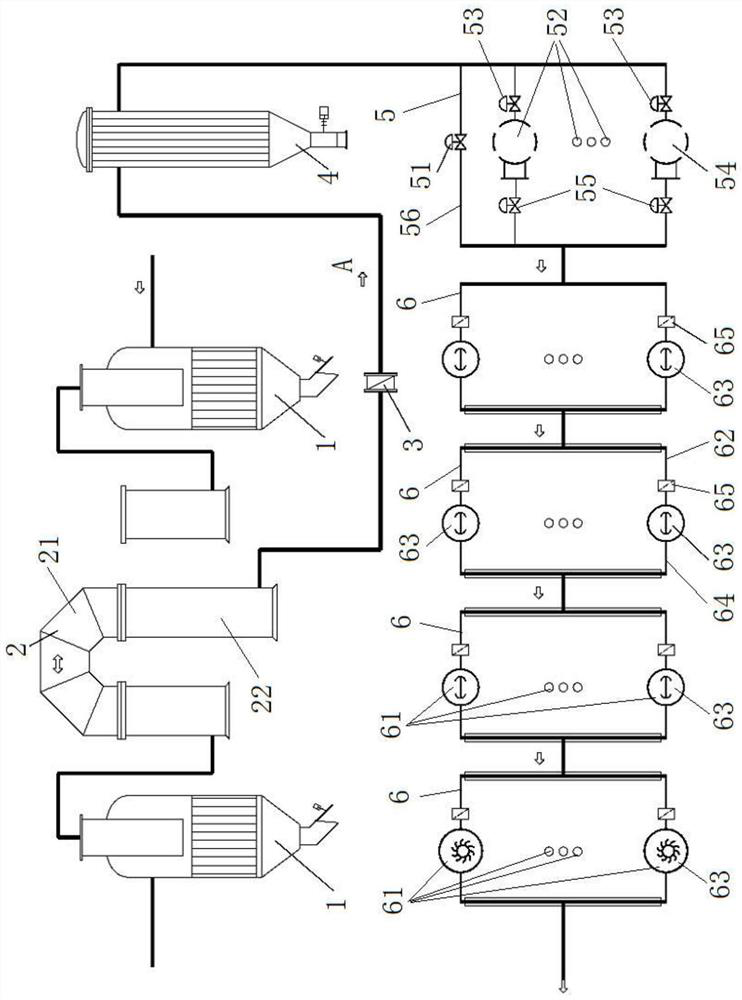

[0029] A vacuum refining exhaust gas treatment system, comprising a primary gas cooling dust collector 1, a pipeline 2, a secondary gas cooling dust collector 4, a dust removal filter group 5 and a vacuum pump group 6 connected in series, such as figure 1 shown.

[0030] Through the coarse dust removal of the primary gas cooling dust collector 1, the secondary gas cooling dust collector 4, and the fine dust removal of the dust removal filter group 5, any dust and sundries can be prevented from entering the interior of the mechanical vacuum pump, and the vacuum pump can be protected to the greatest extent.

[0031] In this embodiment, the vacuum refining exhaust gas treatment system may include...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap