Impurity removing machine for polygonum aviculare

A technology for removing impurities and machines, which is applied in cleaning methods and appliances, chemical instruments and methods, fixed filter elements, etc., and can solve problems such as low cleaning efficiency and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

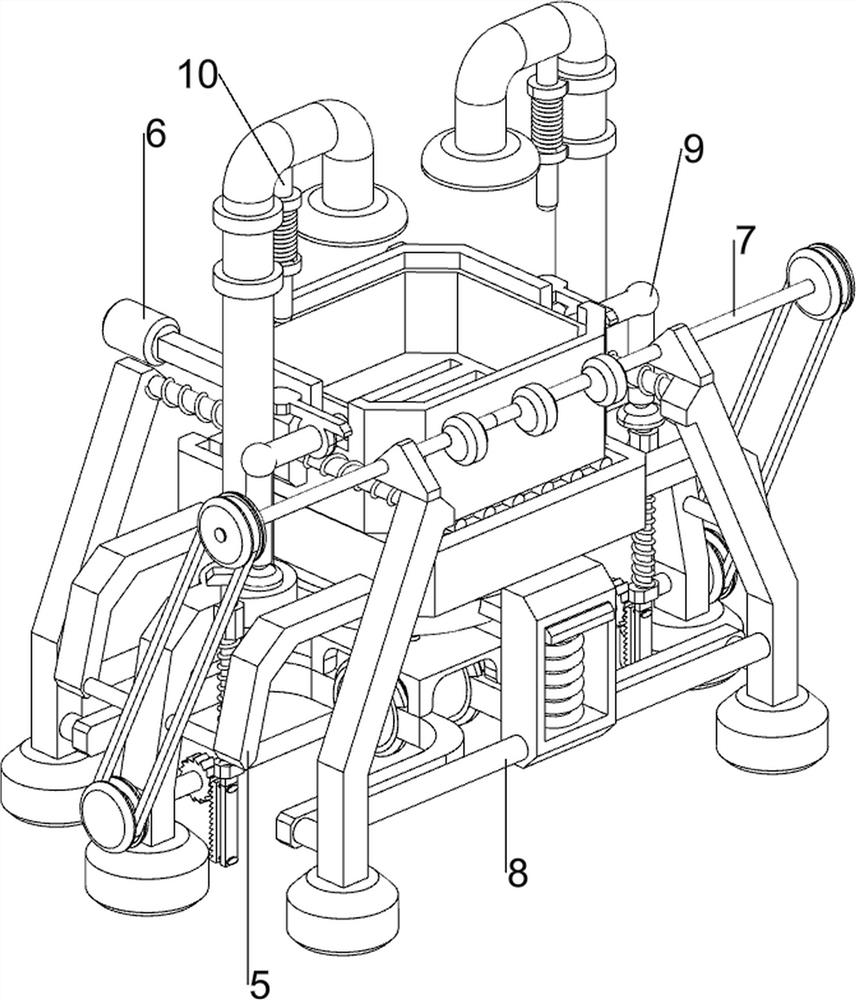

[0027] A machine for flat storage to remove impurities, such as Figure 1-4 As shown, it includes a chassis 1, a bracket 2, a water pipe 3, a nozzle 4, a placement component 5 and a filter mechanism 6. The top of the chassis 1 is provided with a bracket 2, the bracket 2 is provided with a water pipe 3, and the upper part of the water pipe 3 is provided with a nozzle. 4. A placing component 5 is connected between the brackets 2, and a filtering mechanism 6 is arranged on the placing component 5.

[0028] The placement assembly 5 includes a pillar 50, a support rod 51, a first mounting plate 52 and a leaky plate 53. The front and rear sides of the support 2 are connected with a pillar 50, and the pillars 50 are provided with a support rod 51. The first mounting plate 52 is provided with a drain plate 53 on the top of the first mounting plate 52 .

[0029] The filter mechanism 6 includes a filter plate 60, a moving plate 61, a handle 62 and a second mounting plate 63, the top of...

Embodiment 2

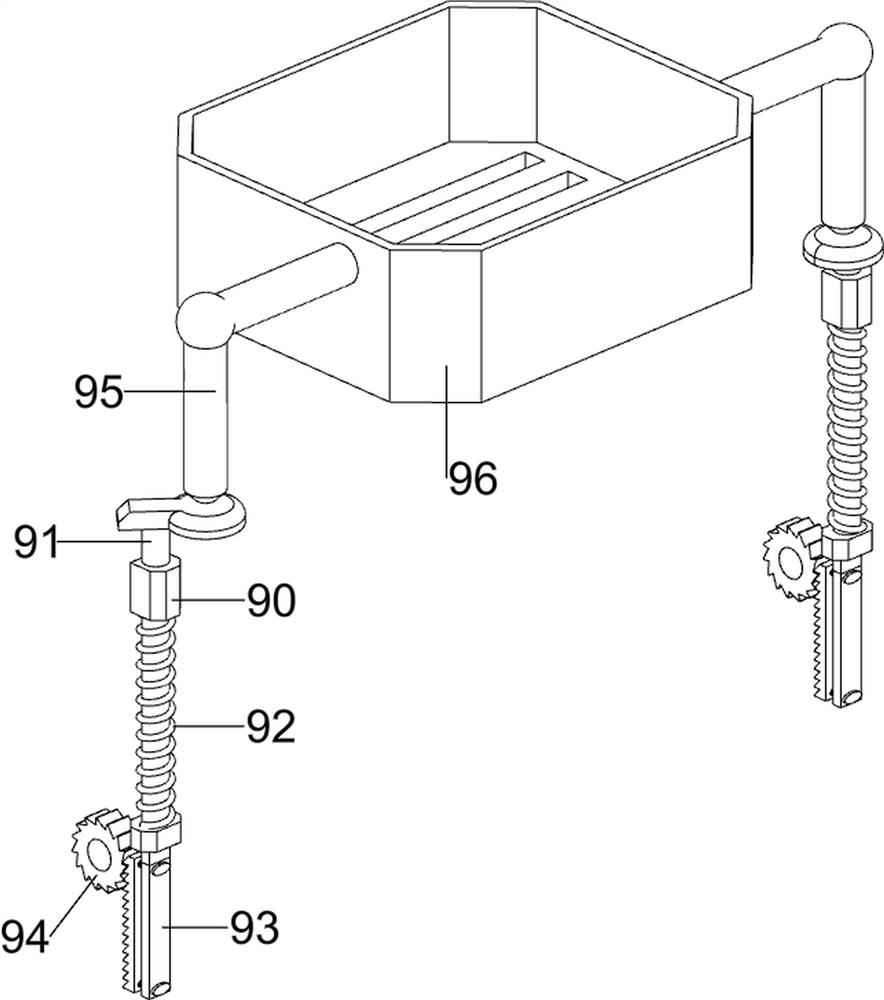

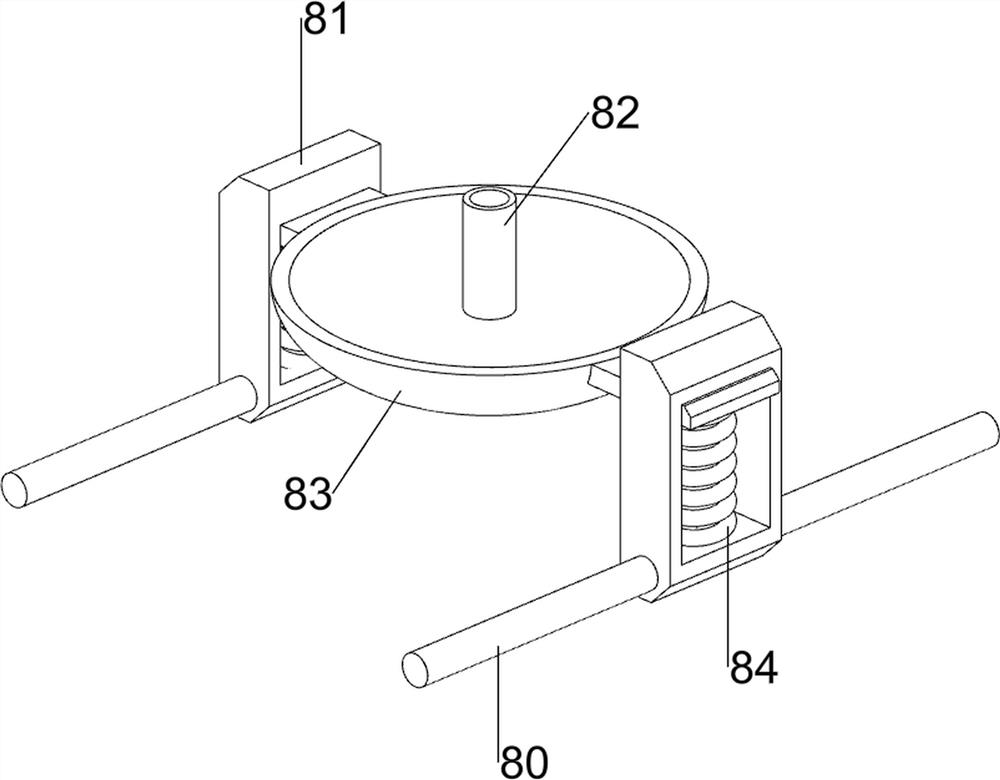

[0032] On the basis of Example 1, such as Figure 5-8 As shown, a shaking mechanism 7 is also included. The shaking mechanism 7 includes a leg 70, a connecting plate 71, a biaxial motor 72, a baffle 73, a rotating shaft 74, a transmission assembly 75 and a first spring 76, which is provided with a connecting plate 71, The middle part of the connecting plate 71 is provided with a baffle plate 73, the four sides of the connecting plate 71 are provided with supporting feet 70, the middle part of the connecting plate 71 is provided with a biaxial motor 72, and the two supporting feet 70 on the front side are rotatably connected with a rotating shaft 74, and the rotating shaft 74 The transmission assembly 75 is connected between the left and right sides and the output shaft of the biaxial motor 72. The transmission assembly 75 is made up of a belt and two pulleys. Between the two pulleys, connecting rods are arranged between the legs 70 on the same side in the longitudinal directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com