3D printing post-treatment cleaning machine

A 3D printing and cleaning machine technology, applied in the field of cleaning machines, can solve the problems of easy fatigue of operators, long cleaning work time, long cleaning time, etc., to achieve the effect of cleaning and efficient, beneficial to physical and mental health, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

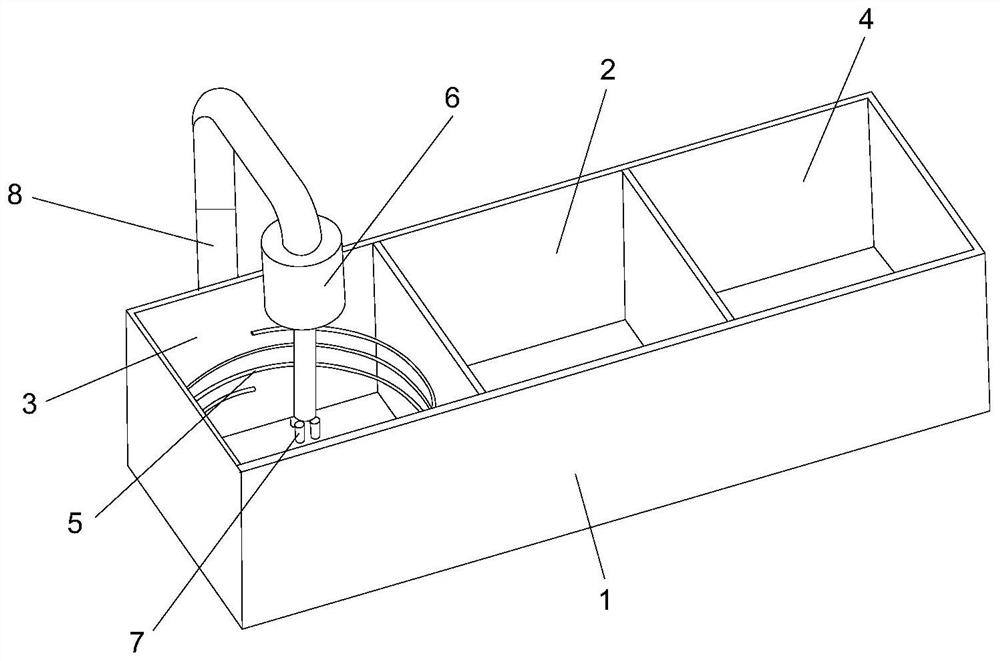

[0013] Such as figure 1 As shown, the 3D printing post-processing cleaning machine of the present invention includes a pool body 1, and the interior of the pool body 1 is provided with independent soaking tanks 2, automatic cleaning tanks 3 and unsupported water grinding tanks 4, soaking tanks 2 and automatic cleaning tanks 3 Cleaning agents are respectively contained inside (the cleaning agent in this embodiment is alcohol), and the automatic cleaning tank 3 is provided with flushing nozzles 5 spirally arranged in the vertical direction, and the pipe walls of the flushing nozzles 5 are arranged at intervals along the spiral direction. A plurality of liquid spray holes, each liquid spray hole sprays cleaning agent towards the center of the automatic cleaning tank 3; the top of the automatic cleaning tank 3 is provided with a rotating motor 6, and the output shaft of the rotating motor 6 is arranged downward and is located in the middle of the spray pipe 5, and the output The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com