Cleaning and drying integrated equipment for textile fabric production

A textile cloth, integrated technology, applied in the field of integrated cleaning and drying equipment, can solve the problems of reduced efficiency, wrinkling of textile cloth, drying after a long time of drying, etc., and achieves the effect of improving efficiency, improving efficiency and improving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

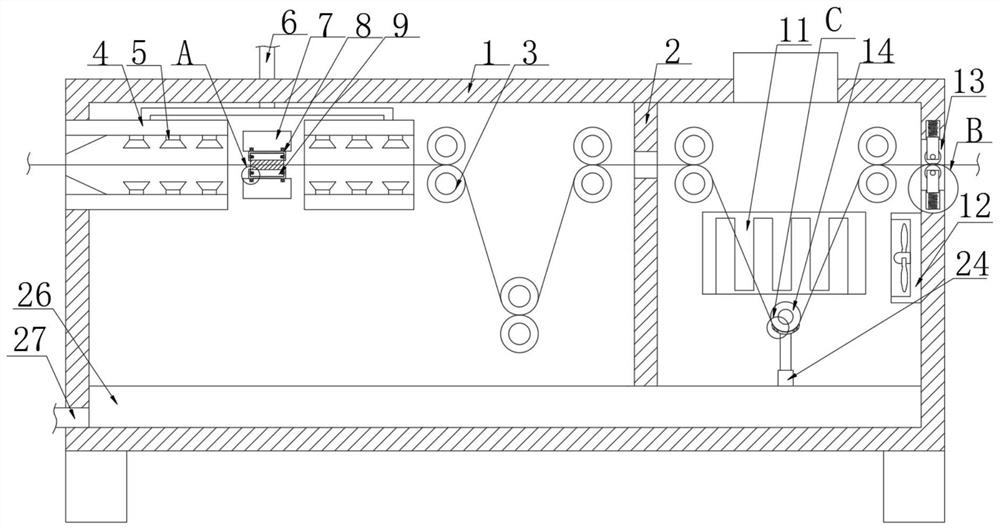

[0023] see Figure 1-3 , this embodiment provides an integrated washing and drying equipment for textile fabric production, including a body 1 and a partition 2, the partition 2 is fixedly connected to the inner groove wall of the body 1, and the inner groove of the body 1 is divided by the partition 2 The second is to set up a cleaning chamber and a drying chamber. By setting a waterproof partition 2 inside the body 1 to separate them into two parts, it is convenient to realize the integrated processing operation of equipment cleaning and drying, thereby reducing the cost of production equipment. At the same time, it also improves the convenience and efficiency of cleaning and drying, and the partition 2 is provided with a through groove, and the inner wall of the cleaning chamber and the drying chamber in the inner groove of the body 1 are both rotated with a guide roller 3, and the body 1 is close to the inner groove wall of the cleaning chamber A cleaning channel 4 is weld...

Embodiment 2

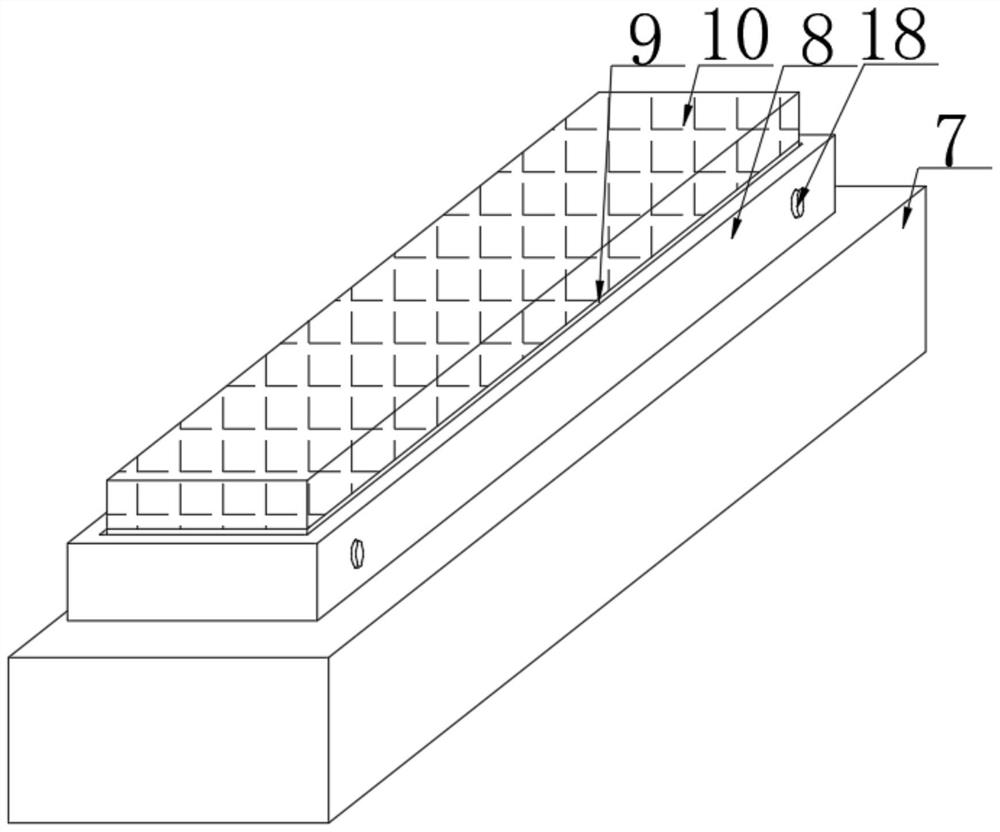

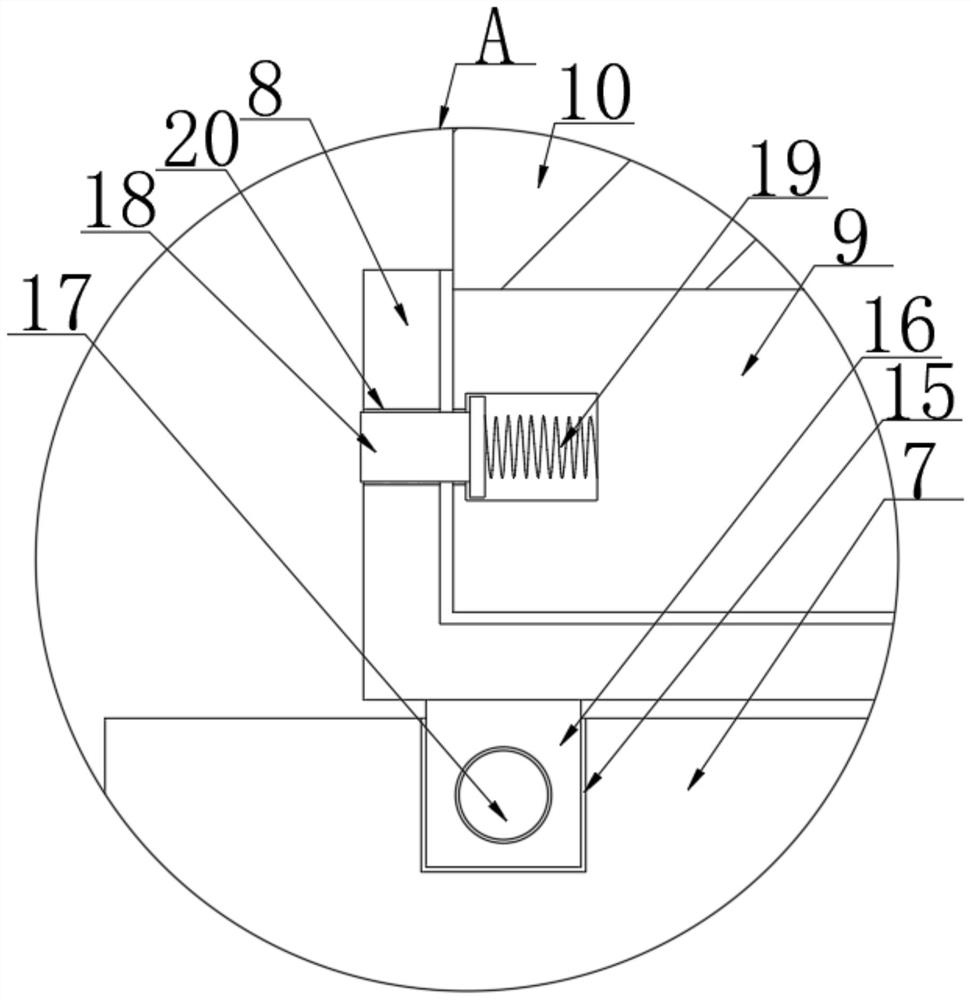

[0029] see image 3 , further improvements have been made on the basis of Example 1:

[0030] One side of the mounting plate 8 relative to the rubbing plate 7 is fixedly connected with a slide block 16, and the slide block 16 is meshed with a chute 15, and the chute 15 is opened on the opposite side of the rubbing plate 7, and one side of the slide block 16 and the inner groove of the chute 15 An electric push rod 17 is connected by bolts between the walls, and the electric push rod 17 pushes the sliding block 16 to slide in the chute 15 at a constant speed, thereby facilitating the driving of the mounting plate 8 and the brush plate 9 to move and knead at a uniform and slow speed, thereby enabling more Efficiently remove impurities and dust on the surface of the cloth. Limiting holes 20 are provided on the opposite sides of the mounting plate 8. The limiting holes 20 are engaged and connected to the limiting posts 18. The positions on both sides of the limiting posts 18 are o...

Embodiment 3

[0033] see Figure 4-5 , further improvements have been made on the basis of Example 1:

[0034] The upper and lower relative positions of the inner groove of the discharge port 13 are penetrated and slidably connected with a bracket 21, and a rebound spring 22 is welded and connected between the bracket 21 and the inner groove wall of the body 1 that runs through and slides, and the bracket 21 is rotated with an ironing roller 23. The inner arc wall of the ironing roller 23 is embedded with a heating wire, and the outer arc wall of the ironing roller 23 is sleeved with a layer of heat-conducting material, and the dried cloth can be dried twice through the ironing roller 23 which is heated at a high temperature. At the same time, the cloth can be ironed to prevent the appearance of wrinkles caused by rapid drying, and ensure the production quality of the product. At the same time, through the rebound of the rebound spring 22 and the bracket 21, the ironing roller 23 can be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com