Prefabricated self-heat-preservation light wall and construction method thereof

A light-weight wall and self-insulation technology, which is applied in the direction of manufacturing tools, building components, ceramic molding machines, etc., can solve the problems of inconvenient inspection of connecting components, complicated preparation process, and indoor use area occupied by inner wall insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

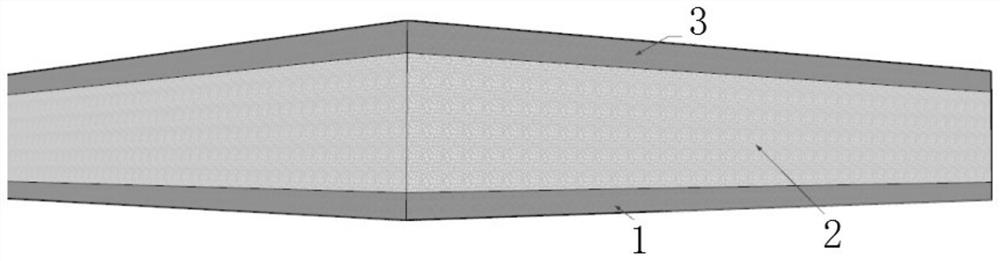

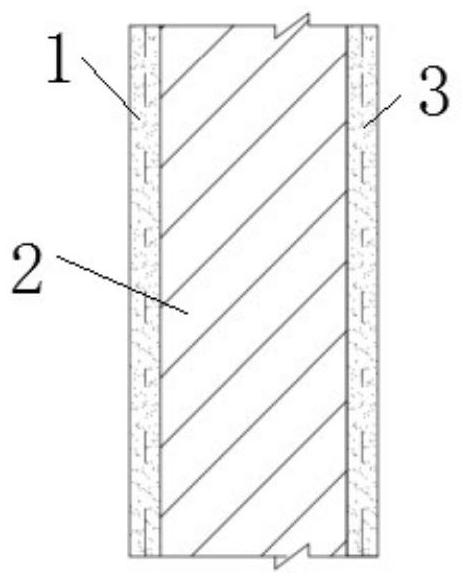

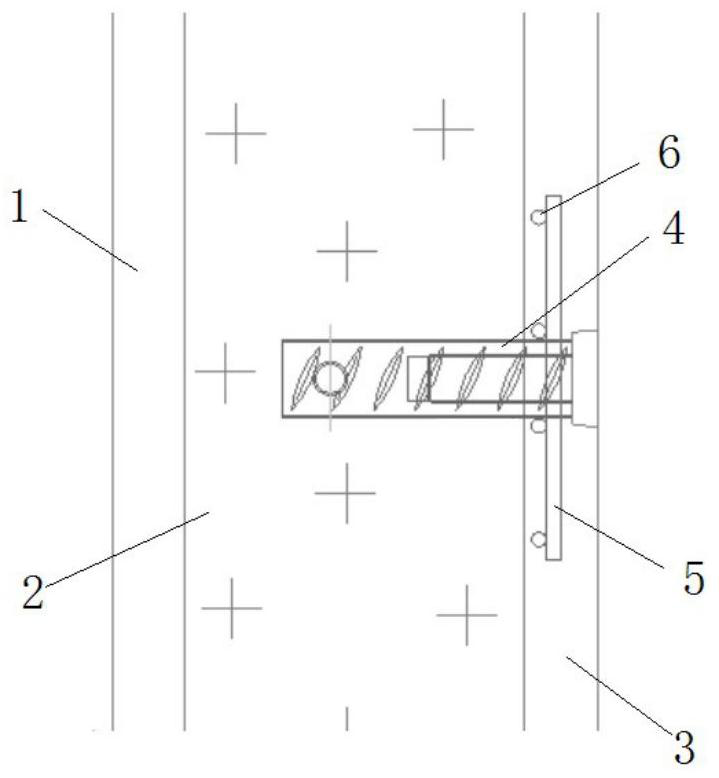

[0022] The prefabricated self-insulating lightweight wall is poured in three layers from bottom to top. The bottom and top are concrete layers made of fine stone concrete materials, and the middle layer is made of cement-based insulation materials. layer. The thermal insulation layer can be at least one or any one of modified cement expanded perlite material, foamed cement material, ceramsite concrete material, and cement-based inorganic thermal insulation mortar material.

specific Embodiment 2

[0024] The prefabricated self-insulating lightweight wall is poured from bottom to top, and the insulation layer in the middle is made of modified cement expanded perlite material. The modified cement expanded perlite material contains cement, expanded perlite, and water, and the weight ratio of cement: expanded perlite: water is preferably 5:3:6. At this time, the thermal insulation effect of the wall can reach the level of 0.08. Reason for optimization: When keeping other parameters unchanged, only adjusting the weight ratio of cement, expanded perlite, and water to 5:6:6, the thermal insulation effect of the wall is below 0.08; only adjusting the weight ratio of cement, expanded perlite, and water When the weight ratio is adjusted to 5:3:6, the thermal insulation effect of the wall is below 0.1; when only the weight ratio of cement, expanded perlite and water is adjusted to 5:1.5:6, the thermal insulation effect of the wall is below 0.12.

specific Embodiment 3

[0026] The prefabricated self-insulating lightweight wall is poured from bottom to top, and the foaming agent in the middle insulation layer does not exceed 30% of the mixing volume. In order to ensure that the performance of the wall reaches the engineering applicability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com